Electric Co-op Shines a Light on Rack Selection

Clay Electric Cooperative was determined to dramatically improve its logistics, reliability, and productivity, even before the Florida member-owned utility set out to build a new warehouse to consolidate maintenance materials from various storage facilities into one location.

The group knew that a new facility was needed to resolve the most-pressing issues of its existing properties, including lowering costs and reducing future downtime. The co-op, which serves about 170,000 accounts and provides service across an area covering 14 northern Florida counties, had ongoing issues with forklifts running into and damaging the racking at its existing facilities. Bidding for equipment at a new warehouse would come down to more than the lowest-cost bid. In choosing value over price alone, the co-op was looking for the best long-term solution.

“The co-op wanted to invest from day one in the proper safety gear to get the most life out of their equipment, since the value of their purchase and the safety of their operations are paramount,” said Buddy Chadwell, president of Kardex Storage, a material-handling equipment distributor in Florida. Because the new warehouse (Figure 1) would not experience high-volume traffic, employees would not be full-time forklift operators, which in the past had increased the instances of forklift impact-related rack damage. The new racking had to be capable of not only withstanding accidents, but also needed to require only minimal maintenance.

Improve Safety, Reduce Costs

Increasing rack resistance to impact can improve safety and operations while reducing the total cost of ownership, including repair and premature replacement. There are several ways to achieve this, which involve choosing the appropriate racking materials and options.

“Typical rack that uses three-sided upright columns with an open back, called open-back roll-form rack, is more susceptible to potential accidents by operators lifting a load too high and backing out,” said Chadwell. “This can place twisting, torsional loads on the rack that can shorten its lifespan and even lead to it tipping over. It is seldom the best choice when the structure must endure frequent or long-term forklift impact.”

A better choice is a cost-effective racking system designed to withstand the increased impact, and then supplement the most impact-prone areas with additional protection. Chadwell conferred with Steel King Industries, a national manufacturer of storage rack and material-handling products, whose engineers reviewed the co-op’s warehouse layout and blueprint.

The engineers recommended a tubular-upright rack product, with a robust four-sided column structure that offers a more suitable choice at a similar price point. For the project, the co-op decision-makers chose SK2000 pallet rack (Figure 2), a boltless, closed-tubular upright product by Steel King.

Compared to open-back roll-formed columns, the closed-tubular uprights are 44 times more torsion/twist resistant, with 250% greater frontal impact resistance and 68% greater side impact resistance. All beams are constructed of high-strength (55,000 psi minimum) steel, and holes are placed on the column’s face, not the corners, minimizing strength loss.

“The tubular rack is much more resistant to rack movement and twisting than open-back channel designs,” said Chadwell. “This translates into a much longer usable lifespan and more operational uptime with minimal maintenance.”

Resistant to Impact

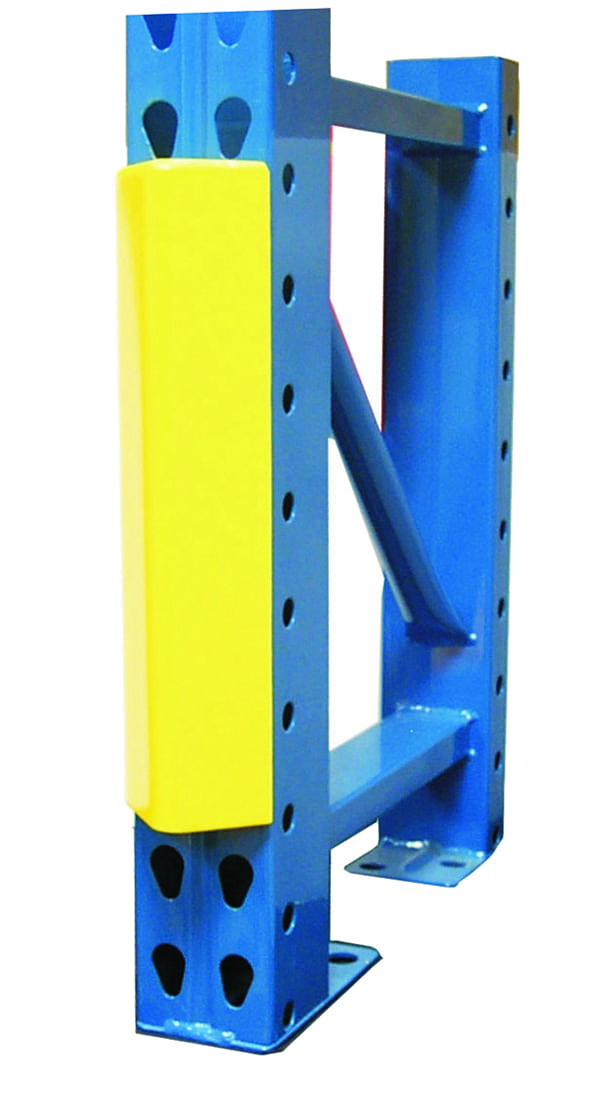

To make its storage racking system even more impact resistant, Clay Electric also implemented an innovative, adjustable, boltless rack-column protector, called Snap-Guard (Figure 3), which safeguards the upright rack column from forklift damage. Constructed of structural angle, with a 4-rivet connection that automatically locks into the upright column, it can be adjusted and removed as needed to protect the desired storage level.

|

| 3. Safeguarding the rack column. An innovative, adjustable, boltless rack column protector, called Snap-Guard, safeguards the upright rack column from forklift damage. Courtesy: Steel King Industries |

“Instead of a typical bolt-on design, the snap-on protector snaps into the rack’s teardrop holes, which makes it very easy to install and adjust,” said Chadwell.

Since a rack upright’s first six inches to a foot of column from the floor is also prone to fork truck impact, particularly at end rows and intersections where maneuvering is tight, Kardex Storage also recommended and installed Guard Dawg guard rail rack protection. The guard rail, constructed of high-strength steel angle, protects upright columns and comes in right, left, or double-ended guards so it is fully compatible with most end row racks.

According to Chadwell, there were distinct advantages to this turnkey approach toward integrated racking versus a less-comprehensive piecemeal approach.

“Too often when a company purchases rack and then tries to mix and match guardrail or other accessories from third-party sources, there can be compatibility or accountability issues,” said Chadwell. “When buying from an integrated manufacturer like Steel King, it is all engineered to work together, with one company taking full responsibility if support is ever needed.”

As for the end result, Chadwell said, “The closed tubular selective rack, with its accompanying guardrail and column protection, is designed to last decades longer than typical open-back rack, with less maintenance and more uptime.” ■

—Del Williams is a technical writer based in Torrance, California.