Coal

-

O&M

World’s Largest Circulating Fluidized Bed Boiler Begins Commercial Operation

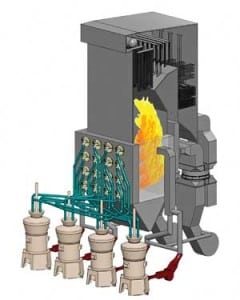

When the Åagisza power plant began commercial operation in late June 2009, it marked the beginning of a new era in the evolution of circulating fluidized bed (CFB) technology. At the heart of this 460-MW plant is the world’s largest CFB boiler, which is also the world’s first once-through unit supercritical CFB boiler.

-

Coal

EPA Tightens Emissions Rules for Coal Processing, Preparation Plants

The U.S. Environmental Protection Agency has adopted final rules tightening emissions limits for coal preparation and processing plants and imposing new reporting requirements on those facilities.

-

Coal

Expect New Mercury Rules by 2011

In a major air regulatory development, the Environmental Protection Agency has agreed to issue rules by November 2011 to reduce mercury and other hazardous air pollution from coal- and oil-fired power plants under a settlement agreement resolving a lawsuit filed by a host of environmental organizations.

-

Coal

EPA Signals Move to Toughen Ozone Standard

The Environmental Protection Agency has decided it will reconsider the 2008 ozone standards issued by the Bush administration, with the agency suggesting in a court that it would toughen the standards because it has concerns about whether standards “satisfy the requirements of the Clean Air Act.”

-

O&M

Four Methods of Fly Ash Sampling

There are four approaches to measuring fly ash content and, therefore, the quality of fuel combustion in a boiler. Before choosing one, you should understand their relative levels of complexity and accuracy.

-

Coal

What Is BACT for CO2?

Assume, for the moment, that the U.S. Congress is unable to agree on legislation aimed at reducing carbon emissions from industry, vehicles, and power plants (the carrot approach). Further, assume that the Environmental Protection Agency (EPA) eventually promulgates rules that require power plants to reduce carbon emissions (the stick approach). Have you given any thought to the range of possible best available control technologies (BACT) that the EPA might require under the Clean Air Act (CAA)?

-

Coal

Three CCS Tests Worldwide

This September — a year after Vattenfall launched the world’s first oxyfuel pilot plant for carbon capture and sequestration (CCS) at the Schwarze Pumpe lignite-fired plant south of Berlin, Germany — three high-profile and long-awaited carbon capture tests started operation around the world.

-

O&M

Condenser Tube Life-Cycle Economics

The decision to retube a heat exchanger or condenser begins with understanding why tubes are failing. Only when the “why” is understood can the economic replacement tube material be selected. We explore the most common tube material failure mechanisms and then illustrate how to perform a proper life-cycle analysis for that new set of condenser tubes your plant so desperately needs. In sum, there are many reasons to consider getting the copper out of your condenser.

-

Coal

Court Revives CO2 “Nuisance” Suit Against Utilities

In another major legal victory for states pressing for controls on industry emissions of carbon dioxide, a federal appeals court has reversed a lower court decision and ruled that eight states and the city of New York City could bring “nuisance” suits against five coal-burning utilities to curb greenhouse gas discharges that the states claim are causing damage to their natural resources.

-

Coal

EPA to Clamp Down on Coal Plant Wastewater

The Environmental Protection Agency announced it plans to “revise” existing, decades-old guidelines for water discharges of toxic metals from fossil fuel-fired power plants, saying a recently concluded EPA study focused mostly on wastewater discharges from coal-fired power plants uncovered elevated levels of toxic pollutants.

-

Coal

EPA Finalizes Greenhouse Gas Reporting Rules

In a major climate change rulemaking, the Environmental Protection Agency has issued final regulations that will require most large emitters of greenhouse gases in the U.S. to report their emissions beginning in 2010.

-

O&M

Texas Wind Boom Cutting into Fossil Generator Profits

Can wind turbines actually reduce the amount of fossil fuels consumed? A Wall Street Journal analysis concludes that ERCOT utilities will begin to feel the squeeze in their profits this year and to expect the amount of fossil fuels used to generate electricity to be reduced.

-

O&M

Zonal Combustion-Tuning Systems Improve Coal-Fired Boiler Performance

Coal-fired power plants that fire low-cost coals or that are equipped with combustion modifications for NOx controls are challenged with maintaining good combustion conditions while maximizing generation and minimizing emissions. In many cases, significant unit derates, availability losses, and an increase in unburned carbon levels can be attributed to poor combustion conditions that occur as a result of poorly controlled local air/fuel distribution within the boiler furnace. Fortunately, a new generation of combustion optimization technologies is available that uses burner air and fuel controls and spatially distributed combustion monitors to detect and correct local furnace air/fuel distribution imbalances.

-

Coal

Top Plants: Bull Run Fossil Plant, Clinton, Tennessee

When TVA’s Bull Run Fossil Plant was erected in the mid-1960s, it could boast of having the largest boiler in the U.S., and the plant has enjoyed a long, enviable efficiency track record. Today the public judges coal plants by their emissions. Now that it’s been outfitted with the most advanced air quality control systems, including the latest flue gas desulfurization system design, Bull Run scores a perfect "10" in both categories.

-

Coal

Top Plants: Hirakud Power, Sambalpur, Orissa, India

Hirakud Power uses environmentally friendly circulating fluidized bed (CFB) combustion technology to produce electricity for one of the world’s oldest aluminum-smelting operations. This "captive power plant" has engineered a number of technical fixes to its original boiler designs to improve plant reliability and reduce outages and boiler repair costs. It also has made strategic investments in upgraded machinery to reduce auxiliary power consumption. In addition to an excellent environmental track record, as evidenced by being Asia’s first ISO 14001 (BS 7750) – certified power plant, Hirakud Power has solidified its position as an industry leader in CFB boiler operating experience and efficient power production.

-

Coal

Top Plants: Hutsonville Power Station, Crawford County, Illinois

This plant’s staff proves that a can-do attitude and high productivity can be compatible with a safer workplace. The proactive approaches they used at the 162-MW Hutsonville plant ranged from improving boiler efficiency to better managing risks to workers.

-

Coal

Top Plants: Nebraska City Station Unit 2, Nebraska City, Nebraska

Omaha Public Power District commissioned Unit 2 at its Nebraska City Station in May of this year. The new 682-MW unit joins Unit 1, which went commercial 30 years ago in the same month. The project is outfitted with all the requisite air quality control systems and sports a very good thermal efficiency. More importantly, the plant will provide reasonably priced power for customers of eight municipal utilities that share ownership of the plant’s electrical output. Those utilities paid for their portion of the construction cost and now receive a like portion of the electrical output from Unit 2 under a unique participation power agreement.

-

Coal

Top Plants: Rockport Power Plant, Rockport, Indiana

Hard work was required at the 2,600-MW Rockport Plant to make improvements to equipment, materials, and processes. But that hard work has paid off: The plant’s units operate much better, employee safety has improved, the facility is setting generation records with both of its 1,300-MW units, and it earned the PRB Coal Users’ Group Large Plant of the Year honors.

-

Coal

Top Plants: Seminole Generating Station, Palatka, Florida

Complying with a corporate environmental policy requires much more than just writing a check for equipment upgrades. It takes a dedicated and knowledgeable staff that’s willing to invest years of work to permanently reduce a plant’s environmental footprint. The staff of Seminole Generating Station have completed multiple, incremental plant improvements over the past decade that have significantly reduced air emissions and minimized solid waste disposal.

-

O&M

Update: Benchmarking Boiler Tube Failures

Boiler tube failures continue to be the leading cause of downtime for steam power plants. Is your boiler tube failure reduction program showing improvement when compared to programs at peer plants? The EUCG’s recent update of its boiler tube failure study can help you answer that question. The full study is available only to members, but this POWER exclusive presents many of the key results, which could help you improve the operation of your plant.

-

Coal

Coal-Fired Generators Worried About Getting Burned

The expected renaissance for U.S. coal-fired generation has been more evolutionary than revolutionary: Less than half of the announced plants will likely progress to construction. However, the percentages for coal-fired plants aren’t significantly different from those for combined-cycle plants a decade ago, when dozens were ultimately canceled, leaving developers with warehouses full of unused gas turbines. The difference this time: The threat of carbon control legislation has moved many projects to the “wait and see” category.

-

O&M

Measuring Coal Pipe Flow

Once pulverized coal flows have been measured, they can be balanced and optimized. Until then, tuning is simply guesswork. The right way to balance furnace fuel flows is to establish solid baseline performance by proper measurement of fuel flow, fineness, and velocity. Only then can all the coal pipes be accurately balanced and followed by a tune-up of the boiler controls.

-

Coal

Enel’s Fusina Hydrogen-Fueled Plant Goes Online

Italy’s Enel said in August that it has successfully begun operating a power plant in Fusina, near Venice, in the Veneto region of Italy, that is fueled 100% by hydrogen. The industrial-sized plant’s building site was officially opened in April 2008, after which infrastructure and technology work was carried out on schedule. Initial testing of the turbine using methane gas was conducted in the spring of 2009, and now — after completion of the special pipeline — the plant has switched to 100% hydrogen fueling, Italy’s largest energy company said.

-

Coal

Combined-Cycle Carbon Capture: Options and Costs, Part I

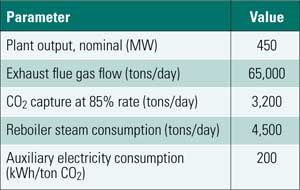

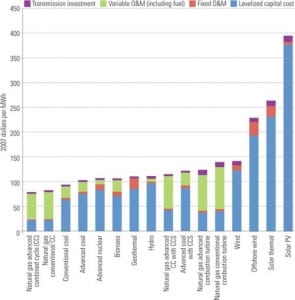

Uncertainty about CO2 emissions legislation is prompting power plant owners to consider the possibility of accommodating "add-on" CO2 capture and sequestration solutions for coal-fired plants in the future. Those same plant owners may be overlooking the possibility that future natural gas – fired combined cycles will also be subject to CO2 capture requirements. This month we examine the capture options. In a future issue, Part II will present the installation and operating costs of different carbon capture technologies.

-

Coal

Report: Costs for First-Generation Carbon Capture Plants Will Soar

Carbon capture and storage (CCS) has of late gained steam as the best way to mitigate emissions of the greenhouse gas carbon dioxide (CO2) from fossil fuel power plants, despite evidence that the approach would require much energy and increase the fuel needs of a coal-fired plant by more than 25%. A new study from […]

-

Coal

Operation of World’s First Supercritical CFB Steam Generator Begins in Poland

The world’s first supercritical circulating fluidized-bed (CFB) steam generator began successful operation at the Lagisza power plant in Poland early this July, according to power equipment and engineering firm Foster Wheeler. The new CFB — believed to be the world’s largest — replaced 1960s-era pulverized coal units at the power plant owned by Polish utility […]

-

Legal & Regulatory

SWEPCO’s Construction Conundrum

"If you build it, they will come" — the litigants, that is. The lawsuit involving the construction of Southwestern Electric Power Co.’s (SWEPCO) John W. Turk Jr. ultrasupercritical coal-fired power plant in Arkansas gives new meaning to that popular quote from the movie Field of Dreams.

-

Coal

Top Plants: Riverside Repowering Project, Minneapolis, Minnesota

Xcel Energy has completed the third and final project required by its 2003 Metropolitan Emissions Reduction Project agreement: repowering the Riverside Plant with a gas-fired 2 x 1 combined-cycle plant and tearing down the old coal-fired plant. Saved from demolition was the Unit 7 steam turbine system that now serves the new plant. Xcel staff expertly managed the project to an on-time start-up and accepted many important construction tasks, harkening back to the days when utilities took a more active role in the design and construction of projects.

-

O&M

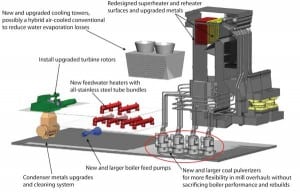

What if New Source Review Were Repealed?

The New Source Review (NSR) permitting program was originally created as part of the 1977 Clean Air Act Amendments to ensure that new power generation facilities were properly outfitted with all the necessary air quality control systems when constructed. Plants in operation were exempt until they made plant modifications viewed as beyond “routine maintenance,” a term whose definition has been a moving target. Is it time for the NSR to take a back seat to improved plant efficiency and reduced carbon emissions?