Siemens Energy Seals Deal for Hydrogen-Ready Coal-to-Gas Switch

European energy giant EnBW will pilot switching a 114-year-old coal-fired waste incineration and district heating power plant in Stuttgart-Münster, Germany, to gas-fired technology while ensuring the regionally significant plant will be ready to combust hydrogen “as quickly and completely” as possible.

Siemens Energy on Nov. 17 sealed an agreement with the utility for an overall package that will ensure all systems at the conversion in Germany’s southwestern state of Baden-Württemberg will be designed “from the very beginning” to enable the natural gas project, which could be operational by 2026, to be fueled with hydrogen.

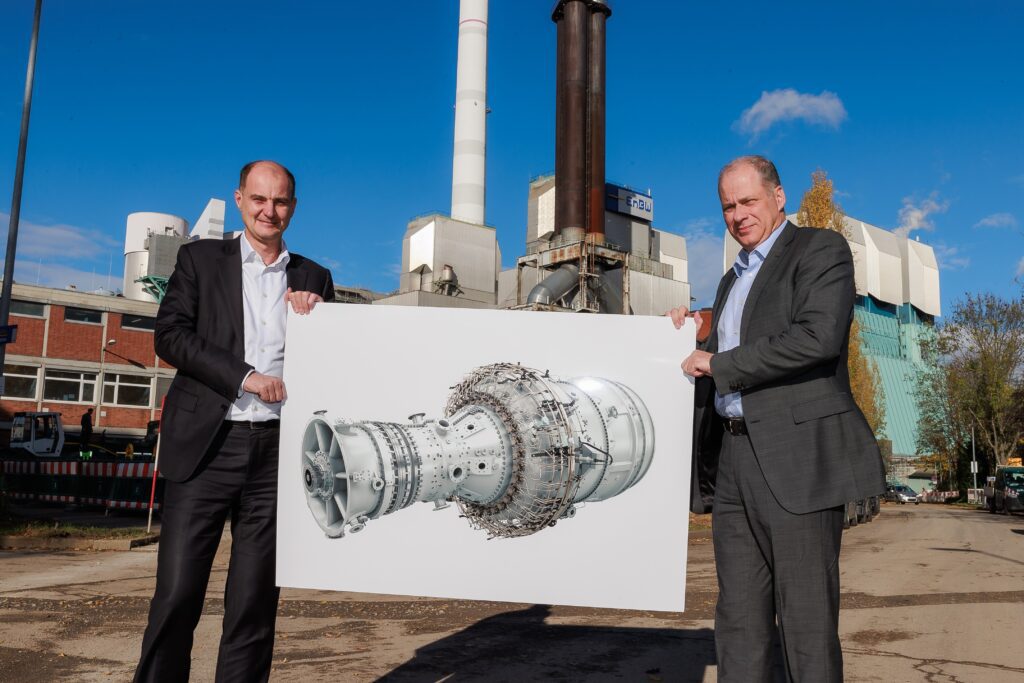

The task will involve installing two Siemens Energy 62-MW SGT-800 gas turbines to replace the Stuttgart-Münster combined heat and power (CHP) plant’s three coal boilers, as well as a downstream waste heat recovery system, the companies said in a joint statement on Thursday. “Pipelines, control systems, and boiler technology also have to be converted as quickly and easily as possible when green hydrogen is available,” said EnBW engineer Diana van den Bergh.

A Hydrogen-Ready Industrial Turbine

Siemens Energy says its current generation of gas turbine models is already able to burn blended fuels containing 30% to 75% hydrogen. The gas turbine manufacturer has set out to enable a 100% hydrogen combustion capability for all its gas turbine offerings by 2030.

The company’s SGT-800 gas turbine, notably, is a compact and modular industrial model that is widely used for CHP installations. Each single-shaft SGT-800 has a 15-stage compressor and 3-stage axial flow turbine, with a rated output of 45 MW and a simple cycle efficiency of 37%. The turbine’s design incorporates an annular combustion chamber with 30 DLE (dry low emissions) burners that are capable of fuel flexibility, including for high-content inert gases, hydrogen, and heavy hydrocarbons in the gas fuel composition, without a maintenance impact.

Under the agreement signed with EnBW on Thursday, Siemens Energy provided an “assurance” that the new turbines will be able to process up to a 75% hydrogen admixture from the time they’re shipped in 2025, but that the overall package will be prepared to handle 100% hydrogen. Siemens Energy’s assurances are bolstered by independent certification of its power plant “H2-Readiness,” which it received from inspection and certification firm TÜV SÜD in November 2021.

EnBW, however, acknowledged that the project’s complete conversion to 100% hydrogen combustion might not be achieved for 10 to 12 years owing to hydrogen supply constraints. “We can’t yet reliably predict when green hydrogen will be available in sufficient quantity and at affordable prices,” noted EnBW Managing Board Member Georg Stamatelopoulos. “But the technology should be in place by that time. We’re not going to put the cart before the horse. Which, by the way, is the objective in all our fuel switch projects.”

EnBW Banking on Coal-to-Gas-to-Hydrogen as Decarbonization Strategy

The project is an important pilot for the EnBW, which wants to complete its gradual phaseout of coal and achieve climate neutrality by 2035. By 2030, the utility plans to decommission approximately 2.5 GW of coal power and achieve “hydrogen readiness” as part of preparations to switch its gas power plants to use hydrogen. Its plans factor in the looming retirement of the 1.4-GW Neckarwestheim II, a nuclear plant that produces about a sixth of Baden-Württemberg’s total electricity consumption.

While mainly driven by sustainability initiatives, EnBW has also set out to reduce its dependence on deliveries of Russian coal. And while the company in 2021 acquired 8,249 GWh of natural gas to generate power and heat, it plans to reduce its gas fuel dependency on Russian suppliers. “Activities in the [liquefied natural gas (LNG)] sector are something that will become increasingly important in the future,” it said in its 2021 annual report released this April. “They will generally open up access to additional sources of supply from global exporters of gas and LNG.”

Along with the conversion at Stuttgart-Münster, EnBW plans fuel switches at Heilbronn, a 1-GW hard coal plant in Heilbronn, and Altbach-Deizisau, a 1.2-GW CHP plant in Altbach. “By switching from coal to gas in Altbach/Deizisau and Münster, we are phasing out coal for the entire so-called ‘Mittlere Neckar Line.’ This means that the biggest overarching district heating system in southern Germany will be coal-free by 2026,” the company said last year.

Stuttgart-Münster, built in 1908, comprises a coal-fired power plant with three coal boilers, a waste incineration plant with three waste boilers, two steam turbines, and a gas turbine plant. The plant has an output of 154 MW and a total thermal output of 450 MWth.

“The treatment capacity of the waste-to-energy plant amounts to 420,000 tonnes per year (reference calorific value 11,000 kJ/kg). EnBW thus makes an important contribution to reliable, environmentally friendly, and economical residual waste disposal in Baden-Württemberg,” the company said. “Residual waste is and will remain the most important energy source in Münster,” it noted. “The city recycles approximately 450,000 metric tons of this waste every year and converts it into electricity and heat.”

“The fuel switch from coal to gas in Münster is an important building block that will allow us to continue to have sufficient power generating capacity in the coming years,” said Stamatelopoulos. “This is the only way we can support the expansion of renewable energy. Today’s agreement shows that we’re taking the next step very seriously. Over the medium term, we’ll be replacing gas as a fossil fuel with hydrogen. We’re already laying the groundwork today. This contributes to our goal of first significantly reducing our company’s CO2 emissions and then becoming climate-neutral by 2035.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).