Innovative Fabric Structures Offer Power Plants Options

The design of a power plant often revolves around efficiency and mapping out operations in a manner that decreases unnecessary expenditures, while increasing productivity. This challenge produces the need for creative industrial solutions that improve operations. Rethinking traditional layouts and implementing new building strategies could be a cost-effective scheme.

Brick-and-mortar buildings are common within the energy industry, and although not necessarily the most-efficient or cost-effective solution, they are generally viewed as the only reasonable option. Fabric structures, however, have begun to disrupt this idea, creating the opportunity to reconsider what a traditional building solution should entail.

While traditional buildings offer reliable coverage, they are greatly lacking in terms of versatility and affordability. They require high upfront costs for materials and construction, substantially greater property taxes, and higher energy and maintenance costs. Even further, traditional buildings generally don’t offer clear span designs and feature internal posts to engineer the building safely. Although brick and metal buildings are the most utilized structures within power plant designs, there is room to reconsider the standard building for smarter business solutions.

Fabric structures fulfill the same functions as conventional buildings, and they often surpass them when compared side by side. It’s time for businesses to strongly consider fabric buildings for their building needs, because they offer versatility, cost savings on a daily basis, and provide the durability required for industrial applications.

Versatility of Application

Fabric buildings offer a versatility to power plants that traditional buildings do not afford. Rather than erecting a single brick-and-mortar building to house operations, sites have the versatility to arrange one or multiple structures in the configuration best suited for their operational needs, because their site and foundation requirements are minimal.

Expansion and growth are expected over time, which has the potential to create a difficult transition period when accommodating additional equipment and operations. The unobtrusive appearance of a fabric building makes it easy to integrate into an existing site as a convenient storage solution and can be easily added near existing traditional buildings or elsewhere onsite. It is also a simple and affordable process to expand an existing fabric building, adding additional square footage to the structure at any time as sites need.

|

|

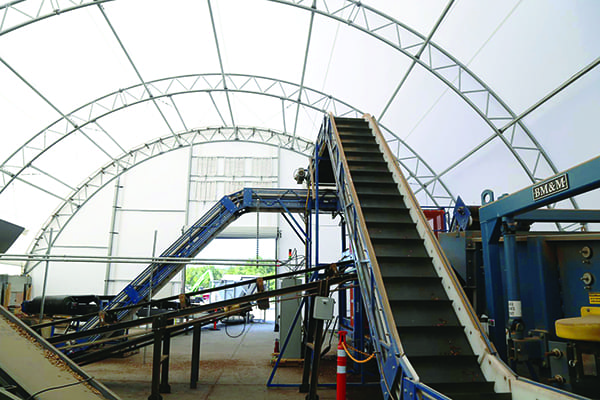

1. Proton Power installed a fabric structure, shown here, to protect its cellulose processing equipment. Courtesy: ClearSpan Fabric Structures |

Proton Power, a generator of clean energy from biomass and waste, chose to invest in a building from ClearSpan Fabric Structures to improve one of its existing sites. The structure currently provides coverage for a cellulose processing machine (Figure 1), protecting the equipment from inclement weather and reducing unnecessary damage from the elements.

Sean Hensley, purchasing and human resources manager of Proton Power, said, “We bought this structure so that we’d have the ability to expand and for mobility if we needed to be able to move it around here on our 30-acre site.”

Fabric buildings provide versatility with their mobile, customizable nature. Each structure can fulfill the specific space and height needs of individual businesses, without reaching the astronomical costs of traditional buildings of the same size.

Those at Proton Power appreciate the versatility of the structure and how it will grow with their adjusting needs over the years. Hensley continued, “The price was great, and we were able to work with ClearSpan’s engineers to make just the right structure for what we needed.”

Saving Time and Money

Power plant engineers will also find the initial investment of a fabric structure significantly less than that of a traditional building. Generally, this is due to far fewer resources required to erect the structure. Many fabric buildings are composed simply of the fabric cover and the steel frame. Traditional buildings require many more materials, such as siding, roofing, and drywall, among many other things, each of which takes additional time and money to build.

With fewer building components, fabric structures offer much shorter construction times. While traditional buildings can take anywhere from months to years to complete, fabric structures often take only days or weeks to build, depending on the building size and number of workers. In fact, experienced build crews are often able to construct up to 5,000 square feet of the fabric building in just one day.

This quick assembly is only advanced when fabric buildings are constructed with temporary foundations, many of which are durable enough for permanent use. Rather than taking time to pour concrete slabs, determining the permanent location of the structure, some companies offer other options to secure the structure to the ground while also allowing for easy relocation down the line.

When selecting the right fabric building, it can also become a great source of money and energy savings in the long run. Because many fabric covers are temperature regulating, they naturally create a more-moderate climate inside, while the translucency allows natural light inside during the day. These features are unique to fabric buildings and reduce the need for additional heating, cooling, and lighting systems, which increase energy requirements, something every business strives to minimize as much as possible.

Geoffrey Ching, director of Sales with ClearSpan Fabric Structures, commented on the savings and convenience he sees customers experience on a daily basis, stating, “Owners of fabric-clad structures experience a brighter, more-natural interior. High-peak designs provide more interior space, creating a cathedral effect that occupants love. Being able to operate without interior lights during daylight hours also promotes significant energy savings and can help owners qualify for green rebates and credits. In some areas, the buildings are also considered temporary and can be exempt from property taxes.”

Owners of fabric buildings not only save on initial construction time and costs, but they also experience significant savings while the building is in use.

Providing Durability

Many people believe that saving money on a building means compromising on structural integrity, but this does not have to be the case, especially on sites such as power plants where unstable infrastructure can become catastrophic. People often cite lack of durability for why they choose not to use a fabric building, expecting the fabric cover to tear at the slightest stretch or the entire frame to blow away with a gust of wind. This is a clear misconception, as fabric buildings can be engineered with just as much strength, if not more, than traditional brick-and-mortar structures.

Reputable fabric building manufacturers offer stamped, engineered drawings to ensure users are receiving a structure that will last, making them just as reliable as metal, wood, or brick buildings. The fabric and frame can be designed to specific regional codes and specifically created to withstand wind, snow, and other weather conditions of the area. In addition to this reliability in design, customers should also look for a warranty to back their building purchase. Steel frames should be backed by at least 50 years under warranty, exhibiting a company that stands by its product and offering peace of mind for users.

Drew Pritchard, an employee of Nuark Warehouse and Logistics, understands the durability of fabric structures all too well. The Arkansas-based company purchased a fabric building as an economical solution to store coal before processing. The structure was a beneficial choice for its expansive space, offering plenty of room to house the large aggregate piles and also providing space for workers and heavy machinery to access the building. It also serves as a necessary coverage solution for the coal, preventing potentially harmful particle emissions into the air and surrounding areas.

After purchasing a fabric building in 2016, Nuark Warehouse and Logistics experienced a tornado on its site just one year later. Pritchard recalled the experience, stating, “In the spring of 2017, we had a tornado touch down about a quarter of a mile behind the building, then raise up and drop down about a quarter of a mile in front of it. The structure made it through 80-mile-per-hour winds with no problem.”

The fabric building, featuring a concrete block foundation, did not require any repairs or replacement after the natural disaster. The building remained in place with the same durability of a permanent structure, and the fabric cover withstood high winds and flying debris without a tear. Pritchard continued by expressing his satisfaction with the fabric structure’s durability and said, “I do recommend the ClearSpan building. It has held up great.”

|

|

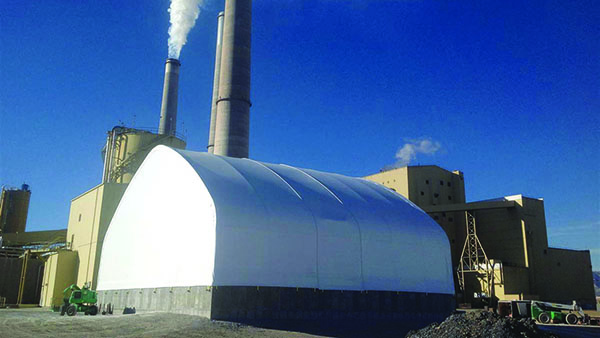

2. Although the fabric structure shown here has a permanent footing, structures can also be designed with temporary foundations, many of which are durable enough for long-term use. Courtesy: ClearSpan Fabric Structures |

Users are often impressed with the sustainability their fabric building provides (Figure 2). Not only are they a durable choice with the same reliability as any other building, they offer the advantage of convenience and flexibility. Fabric buildings with a clear span of space can provide many solutions for power plants, from housing aggregates to equipment protection and storage, and even the potential to serve as office space.

Fabric structures are also suitable for sites of any size and can be built to hundreds of feet in length and width. They create the open space necessary to increase operational efficiency and ultimately boost business profits. Translucent fabric covers, perhaps the most unique and beneficial aspect of the structures, allow natural sunlight to fill the space during the day and regulate inside temperatures. These energy and cost savings, alongside the versatility and durability of the structure, provide the sustainability power plants need to grow and advance into the future. ■

—Nicole Pulyado is the public relations and digital content specialist with ClearSpan Fabric Structures.