High-Performance Synthetic Rope Allows Craneless Wind Turbine Blade Replacement

Replacing blades on a wind turbine is not a simple task. Blades range from 40 to 60 meters in length and can weigh 16 tons or more. Combined with hub heights that can exceed 100 meters and locations that are, by definition, subject to prevailing winds, replacing blades becomes challenging. Add in the cost of a mobile crane capable of hoisting the weight to the required heights (as much as $150,000 to $200,000 per job) and the scheduling challenges of getting equipment on-site, blade replacement can become a major expense in both time and capital.

Eliminating the Crane (and Expense)

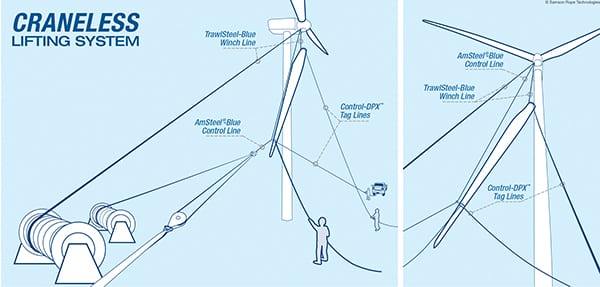

One turbine manufacturer, faced with the need to replace several blades in various locations, devised a craneless blade replacement system using high-performance synthetic ropes developed by Samson Rope Technologies Inc. Using a purpose-built, portable, skid-mounted winch system capable of both hoisting and controlling the blade as it is moved into position on the hub, blades were changed without the need for a mobile crane (Figure 1).

|

| 1. Reaching new heights. Winch, control, and tag lines made of synthetic rope allow the safe replacement of wind turbine blades without the use of a crane. Courtesy: Samson Rope Technologies Inc. |

Initially, steel-wire rope was considered for the system, but when the components for a three-part lifting/lowering system (main lifting/lowering line, tag lines, and control lines) were added to the weight of the wire itself, an alternative was sought. The snatch block and crane blocks required to meet the D/d ratio—the relationship between the drum diameter (D) and the wire rope diameter (d)—for steel-wire rope weighed more than 400 pounds, making it extremely difficult to maneuver within the limited confines of the rotor’s hub. It was quickly determined that synthetic lines would be preferable to steel-wire rope.

Synthetic ropes offer the same, or higher, strength compared to steel-wire ropes at greatly reduced weights and manageable D/d ratios for the hardware. In addition, the lighter weight allows easier handling. Dangerous fish hooks from broken wire strands are completely eliminated. The result: safer, more efficient operations.

Not All Synthetic Rope Is Created Equal

The synthetic rope chosen for the initial testing (a non-Samson product) proved unsuitable—it was diving, that is, pushing into the previously wrapped level below it on the winch drum, causing slack to form as the load was lowered. The result was a series of short free-falls as the slack sections on the drum came under load. The jerky descent was hard to control and had the potential to subject the rope to shock loading.

With wind a factor at the turbine sites, managing the orientation of the blade with the tag line as it was being hoisted was critical. The original synthetic tag lines purchased for the job had far too much elastic elongation to allow proper control of the blade as it was hoisted into position, allowing the blade to pendulum back and forth, potentially damaging the blade or the turbine tower in the process.

Assistance sought from the rope’s supplier and manufacturer didn’t produce any information that was helpful in resolving these issues. After extensive online research, the engineering team contacted Samson for information on products that could be used in this unusual application. Michael Quinn, director of sales and Samson’s main contact for crane applications, got involved and brought Dustin Heins, one of Samson’s application engineers, into the mix.

The customer’s engineering team quickly discovered the benefits of working with a manufacturer willing to partner with customers to help solve critical problems. With a considerable amount of technical information available online and the assistance of Samson’s sales and application engineers for suggestions, test results, and detailed specifications, Samson’s TrawlSteel-Blue was selected as the main hoist line.

New Application for a Proven Material

TrawlSteel-Blue is a 12-strand single braid made with Dyneema fiber for exceptional strength and light weight. It was originally developed for the commercial fishing industry for use as a winch-based trawl line. The addition of a non-load-bearing polyester control core gives this rope cross-sectional firmness for superior performance on winch drums. It keeps its round shape and packs well on the drum.

Ropes made with Dyneema fiber are typically 85% lighter than the steel-wire ropes they replace, making handling easier and reducing demands on the winch. In addition, a better D/d ratio allowed the use of smaller snatch blocks for the multiple-part main hoist line, saving weight and enabling the crew aloft to rig the hoist much faster within the space constraints of the rotor’s hub. The overall result was a more efficient operation.

A control line and a tag line were also rigged from two separate, smaller winch drums on the skid (Figure 2). These were both AmSteel-Blue, Samson’s flagship 12-strand single braid with a proven track record for strength and durability. Another pair of tag lines was used to help keep the blade from twisting during the hoist. Because these were operated from capstans, they required a higher coefficient of friction than the winch-based ropes. For these lines, Control-DPX was used.

|

| 2. Craneless lifting system. High-strength synthetic rope allowed wind turbine blades to be changed at a significantly reduced cost. Courtesy: Samson Rope Technologies Inc. |

Control-DPX is a 12-strand rope made with Dyneema fiber and Samson’s patented DPX technology. It blends the high coefficient of friction of spun polyester with the strength of Dyneema fiber to create a rope that excels on capstans, stoppers, and cleats. Control-DPX has the added feature of having an extremely “soft hand” for ease of handling and very low elongation for better control of the blade during the operation.

LFS Marine & Outdoor, a Samson distributor headquartered in Bellingham, Wash., supplied all the ropes used. LFS is a supplier to the commercial fishing industry with extensive experience with TrawlSteel-Blue.

Shea Kirkpatrick of LFS took charge of the order, working directly with the engineers to fabricate all ropes to their specific length and fabrication requirements. LFS supplied a combined total of 1,900 feet of TrawlSteel-Blue, AmSteel-Blue, and Control-DPX for the first outing, and an additional 2,100 feet for the subsequent outing.

When one of the ropes needed to be spliced in the field, and there was only about an hour to get it done, Kirkpatrick supplied easy-to-follow splicing instructions—complete with photos—that allowed the on-site team to perform the splice with the confidence that it was done correctly and would be safe to use. All of the ropes performed well and are being used for multiple blade replacement projects.

—Jeff Smith is partner/creative director for Smith Walker Design.