Commercialization Boost for Cobalt-Eliminating Battery Technologies Developed at ORNL

Energy Storage startup SPARKZ Inc. has exclusively licensed five technologies from the Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL) designed to eliminate cobalt in lithium-ion batteries. The development portends a significant new direction for battery storage technology, which has been hindered by costs and availability of the rare metal.

ORNL, which announced the licensing deal on Feb. 5, said the collaboration with SPARKS, a firm founded in 2019 by scientist, entrepreneur, and former DOE Energy Investor Center director Sanjiv Malhotra, would help accelerate the transition of the advanced battery technology suite to the marketplace and help accelerate production of electric vehicles and grid-related energy storage solutions.

Cobalt: A Tainted Commodity

Cobalt is a rare, costly, and difficult-to-access element that increases the performance but reduces the safety of lithium-ion batteries. “The metal is specifically used in a battery’s cathode, the positively charged end that determines much of a battery’s performance. However, because cobalt is costly and mined overseas, finding alternative materials has become a top priority,” ORNL said.

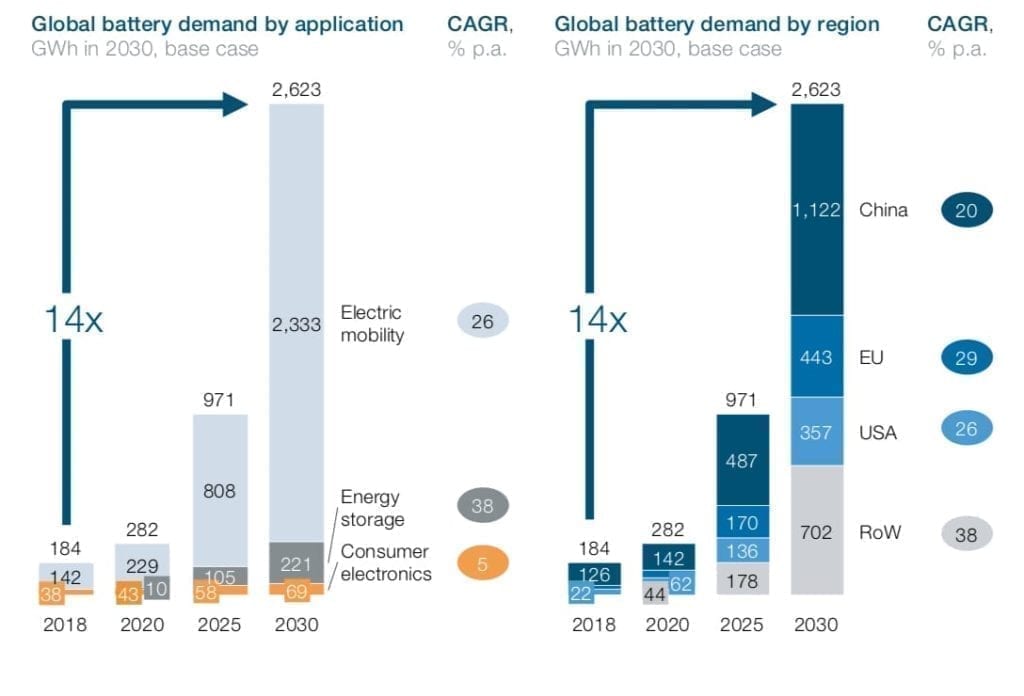

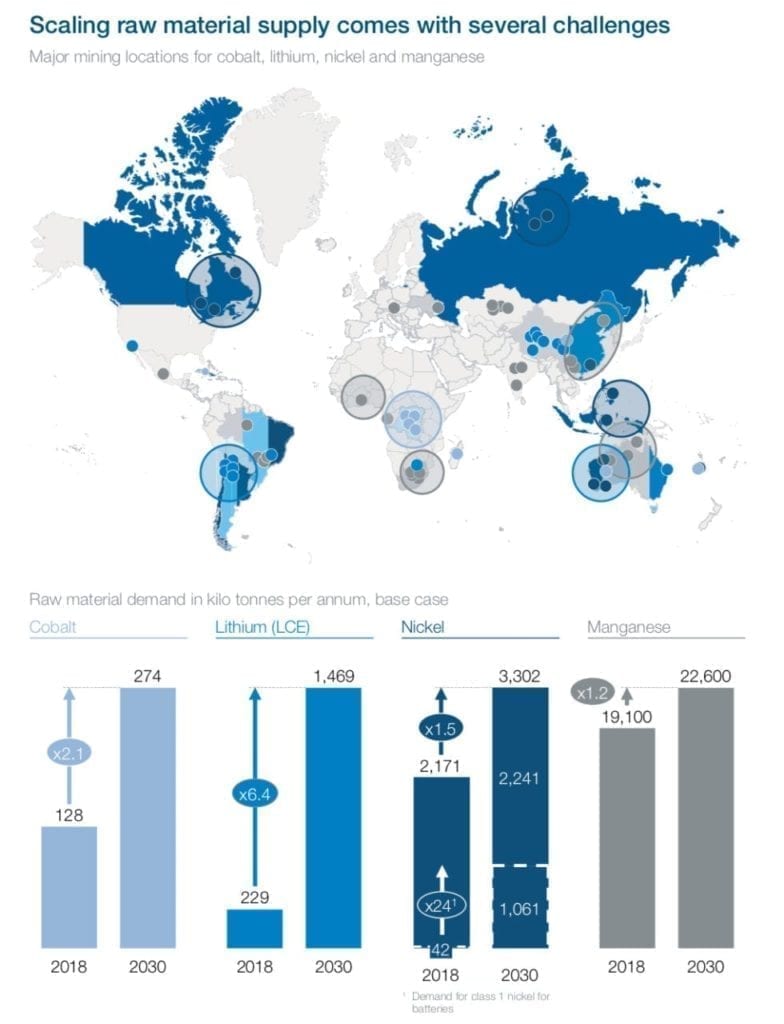

According to the World Economic Forum’s (WEF’s) Global Battery Alliance, batteries will be a major near-term driver to decarbonize the road transportation sector, but a key challenge hindering their widespread deployment is “responsible and sustainable” battery production. The alliance projects that to meet soaring demand, capacities along the full production value chain—from mining through cell production and recycling—will need to ramp up. Raw material demand driven by battery applications, specifically, will experience “unprecedented growth” in the coming years, including for lithium, nickel, and cobalt, it predicts.

Supply of lithium, which is well distributed in the Earth’s crust, will need to increase by a factor of six between 2018 and 2030. Battery demand for high-purity class 1 nickel will increase by a factor of 24 through 2030, “putting the market under pressure in the next few years.” Cobalt’s demand, meanwhile, is expected to surge by a factor of four—doubling overall global demand by 2030. About 70% of today’s mined cobalt—almost exclusively as a byproduct commodity, obtained mostly from copper and nickel mines—comes from the Democratic Republic of Congo (DRC), where up to 30% is extracted by hand using basic tools in “artisanal small-scale mines.” About 60% of cobalt refining operations are situated in China. However, the alliance notes that the surge in cobalt demand poses grave social, environment, and integrity risks. “Severe social risks have been well documented in the DRC’s artisanal mining industry. They include hazardous working conditions; deaths due to poorly secured tunnels; potentially various forms of forced labour; the worst forms of child labour; and exposure to fine dusts and particulates and DNA-damaging toxicity.”

A Suite of Cobalt-Eliminating Battery Technologies

According to ORNL, partly owing to these reasons, finding cobalt alternatives “has become a top priority.”

“The hallmark of Oak Ridge National Laboratory’s technologies is developing low-cost, cobalt-free cathode materials without compromising on energy density,” said Jagjit Nanda, a principal investigator on several of the licensed technologies, who works in ORNL’s Chemical Sciences Division.

The suite of technologies licensed by Castro Valley, California–based SPARKZ includes:

- High energy density secondary lithium batteries. The technology involves a high-density lithium battery design that uses novel cathode and anode compositions to overcome energy density limitations of existing technologies for more efficient rechargeable batteries. Energy density, or the amount of charge that a given quantity of a material holds, “is especially important for electric vehicles,” ORNL noted. “Fast-charging, energy dense batteries developed by ORNL and scaled by SPARKZ could allow electric charging stations to take over as the ‘gas stations of the future.’ ”

- Cobalt-free layered oxide cathodes. This technology involves a “low-cost, cobalt-free” cathode material that was created for the development of improved lithium-ion batteries.

- Nonaqueous electrolyte with lithium bis(fluorosulfonyl)imide salt for fast charging/discharging of Li-ion batteries. “Electrolytes are the liquid medium by which cathodes and anodes ‘talk’ to each other in batteries by exchanging electrons,” ORNL explained. The new electrolyte formulation allows faster charging for lithium-ion batteries and can perform at a 23% higher capacity during a 12-minute charge than other formulas, it added.

- Early transition metal stabilized high capacity oxidatively stable cathodes of lithium-ion batteries. This technology improves on lithium-ion cathodes by replacing early transition metals, namely cobalt, at relevant sites in cathodes, and by varying the lithium composition, ORNL said.

- Battery materials scale up and processes. A manufacturing innovation, this technology enables industrial-scale production of battery materials through a series of chemical processes.

SPARKZ said it is now evaluating a location for a research and demonstration and prototyping facility in the U.S. to scale these technologies to meet the demands of customers in the mobility and grid sectors. “We have chosen Oak Ridge National Laboratory to be our partner because ORNL provides all those functionalities which are essential to get a product rapidly to market; namely, access to the world’s best battery technologists, or human capital; access to the best technology, or intellectual capital; and access to the best infrastructure,” said SPARKZ CEO Sanjiv Malhotra.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine)