Instrumentation & Controls

-

Instrumentation & Controls

Thermocouple Response Time Study for Steam Temperature Control, Part II

Mismatched or poorly maintained temperature sensors and thermowells can cause an often-unrecognized error in steam temperature measurement. The problem is often recognized only when sluggish steam temperature response times are noticed. Recent tests suggest some simple ways to resolve the problem.

-

Environmental

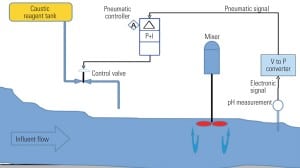

Sediment Pond Effluent pH Control

Many power plants have sediment retention ponds that require control of pH for the effluent. The following guidelines for fossil plant sediment pond pH control will help you design a robust system while staying within budget.

-

O&M

DHS: USB Drives Spread Malware in Control System Environment at Two Power Plants

A report by the U.S. Department of Homeland Security (DHS) Industrial Control Systems Cyber Emergence Response Team (ICS-CERT) reveals that infected USB drives spread common and sophisticated malware in the control systems at two power plants in separate incidents late last year.

-

Instrumentation & Controls

The Electric Grid: Civilization’s Achilles Heel?

Solar flares have proven destructive effects on transmission grids, but there are many other “black swan events” that threaten modern civilization. Experts disagree about which protective steps should be taken today.

-

O&M

As Cybersecurity Bill Dies, Newly Declassified Report Underscores Grid Vulnerabilities

Despite growing concern about cybersecurity both in and outside of Washington, the Senate’s cybersecurity bill died a second time on Nov. 13. The apparent inability of Congress to pass legislation designed to protect critical U.S. infrastructure could lead to President Barack Obama implementing some of the bill’s provisions via executive order. A day after the bill failed to gain 60 votes for passage, a recently declassified report was released that finds the U.S. power grid is vulnerable to attacks that could be more destructive than natural disasters such as Hurricane Sandy.

-

Nuclear

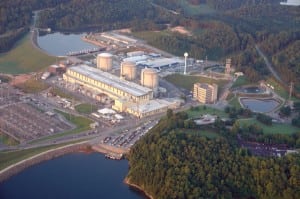

Top Plant: Oconee Nuclear Station, Seneca, South Carolina

With license extensions for its three units in hand, Duke Energy’s Oconee Nuclear Station began a digital controls upgrade program in 2006, and in January 2010, AREVA became the first supplier to receive Nuclear Regulatory Commission approval for a safety-related digital instrumentation and controls system.

-

Instrumentation & Controls

Chinese Hackers Blamed for Breach of Telvent’s SCADA-Related Network

Cyber attacks on the utility industry are no longer theoretical. According to multiple sources, smart grid technology vendor Telvent told U.S., Canadian, and Spanish customers on Sept. 10 that hackers had broken through its firewall and accessed “project files” related to its OASyS SCADA system. On Wednesday, reports surfaced that, based on the perpetrators’ “digital fingerprints,” the attack appears to be the work of a well-known Chinese hacker group.

-

Distributed Energy

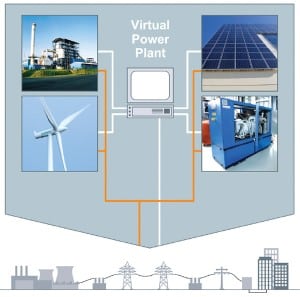

The Rise of the Virtual Power Plant

Siemens Infrastructure & Cities and Munich city utility Stadtwerke München (SWM) this April put into operation a virtual power plant (VPP), linking several small-scale distributed energy sources and pooling their resources so they can be operated as a single installation (Figure 1). The project comes on the heels of a February 2012 expansion of a […]

-

Instrumentation & Controls

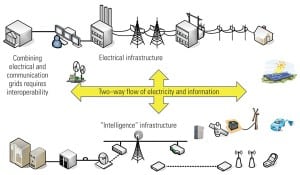

Guidance on Cybersecurity for the Electricity Sector

The cybersecurity needs of the electric power industry are unique, due to the critical nature of the product and the wide range of technologies that must be considered—from complex, modern industrial control systems to aging infrastructure elements.

-

O&M

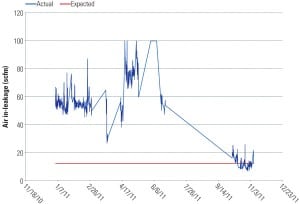

Improve Condenser Performance Through Better Instrumentation

Most power plants use some form of condenser performance-monitoring protocol. Some of those protocols are deficient because the proper instrumentation is not installed to collect the necessary data. Three case studies illustrate how collecting good condenser performance data enabled plant staff to troubleshoot problems and make good plant performance improvement decisions.

-

Instrumentation & Controls

Ensuring the Cybersecurity of Plant Industrial Control Systems

Industrial control systems (ICSs) manage global industrial infrastructures, including electric power systems, by measuring, controlling, and providing a view of control processes that once were visible to the operator but now are not. Frequently, ICSs are not viewed as computers that must operate in a secure environment, nor are they often considered susceptible to cybersecurity threats. However, recent cybersecurity failures have proven these assumptions wrong.

-

Instrumentation & Controls

Upgraded Controls Position McIntosh Plant for Efficient Operations

Lakeland Electric’s C.D. McIntosh, Jr. Power Plant is a microcosm of the entire power generation industry. On a single site is a once-baseload coal-fired plant that is now operating fewer hours plus a peaking gas-fired combined cycle plant that has swung to baseload operation. A complete controls upgrade of the gas-fired plant last year prepared the plant for its expanded role in producing electricity for this 108-year-old public power provider.

-

O&M

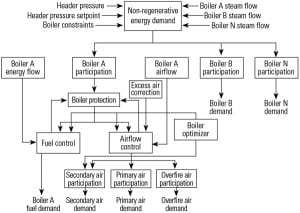

Intelligent Control of FBC Boilers

Optimizing combustion control is critical to reducing emissions and increasing plant operating efficiency, particularly for fluidized bed combustion (FBC) boiler plants burning biomass fuel that has unpredictable moisture content. The secret: measuring actual energy flow.

-

Instrumentation & Controls

Power Generation: Automation Today and Tomorrow

Handheld smart devices providing custom applications and Internet access at the touch of a virtual button are common today. Hidden beneath their touchscreens is a global network of digital technologies that respond to each command. Will these familiar commercial technologies and apps make their way to industrial digital control systems?

-

Nuclear

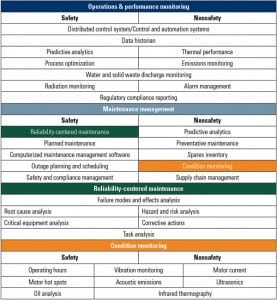

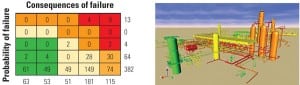

Comprehensive Asset Management for Nuclear Plant

Asset management means different things to different people. But it boils down to converting raw data and observations about equipment and components into information and knowledge that is then used, propagated, and shared by workers and digital components to manage performance. Nuclear plants have special asset management needs, given the level of their safety, reliability, and regulatory requirements.

-

Coal

Enhanced Load Dispatch Rate and Furnace Protection Through Model Predictive Control

The enhanced plant performance achieved at the 1,477-MW Morgantown Generating Station shows the value of model predictive control in conjunction with intelligent distributed control algorithms. This project update looks at how the project team moved from ramp rate improvements to reducing tube metal temperatures to improved component life.

-

Instrumentation & Controls

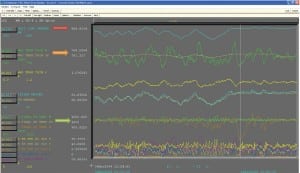

Monitoring Control Loop Performance

Control loop performance-monitoring software can help to improve loop performance at electric power plants by automatically collecting data, assessing several aspects of loop performance, and providing the results in reports and user interfaces.

-

Nuclear

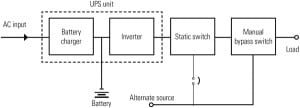

Specifying Nuclear DCS Power Supplies

The consideration of power supplies has become critical to the success of converting analog instrumentation and control systems to digital control systems (DCSs). Careful planning is particularly necessary for nuclear power plants, where instrumentation systems are required for safely shutting down a reactor, mitigating the consequences of an accident, and performing post-accident analysis.

-

Nuclear

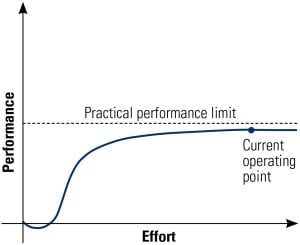

Crossing the Digital Divide

One of the great successes of the power generation industry over the past two decades has been the significant increase in nuclear plant reliability and other performance standards. However, there is reason to be concerned that the design, operation, and maintenance practices used by the current fleet of plants do not leverage all the possible advantages from a digital controls upgrade. Perhaps past success is the biggest barrier to future success.

-

Instrumentation & Controls

Managing Equipment Data Through Asset Virtualization

Asset “virtualization” extends and combines the technologies of 3-D visualization and virtual reality to a new, practical level for the life-cycle management of power industry equipment. All pertinent data for a component, subsystem, or plant is associated with, stored, and accessed through as-built 3-D digital models of the actual plant that are constructed using laser scanning techniques.

-

Instrumentation & Controls

NERC CIPS Update: The Advantages of an Integrated Factory Acceptance Test

When adding, modifying, or upgrading a system, many critical infrastructures conduct a factory acceptance test (FAT). A FAT includes a customized testing procedure for systems and is completed before the final installation at the critical facility. Because it is difficult to predict the correct operation of the safety instrumented system or consequences due to failures in some parts of the system, a FAT provides a valuable check of these safety issues. Similarly, because cyber security can also impact the safety of critical systems if a system is compromised, it makes sense to integrate cyber security with the FAT.

-

O&M

The New Water Lab

Recent advances in water laboratory instrumentation—from improved sample conditioning to advanced online instruments—have reached the market. Here’s a look at the equipment you’ll find in the best-equipped power plant laboratory this year.

-

Instrumentation & Controls

Twin Pac Controls Upgraded

In November 2008, a central Texas utility commissioned HPI, a full-service turbomachinery design and construction firm based in Houston, to perform a major upgrade of its plant’s power distribution and turbine control systems.

-

O&M

Artificial Intelligence Boosts Plant IQ

Neural networks have already found practical application in many plants, and recent advancements in artificial intelligence promise to shape the design of the next generation of power plant supervisory controls. Will future plant operators be fashioned from silicon?

-

Instrumentation & Controls

K-Power Upgrades Combined- Cycle Automatic Generation Controls

Tightly managed grids require combined-cycle plants equipped with power block controls that can quickly respond to automatic generation control signals with minimal error. K-Power’s successful controls upgrade demonstrates that that goal—and more—is achievable.

-

Instrumentation & Controls

Fully Automating HRSG Feedwater Pumps

Modern distributed control system platforms can provide many tools to capture best operating practices and automate them. This case study shows the steps taken to automate a hypothetical simplified feedwater pump system for a combined-cycle power plant. It describes a combination of controls automation strategies and human-machine interface techniques designed to increase the overall level of automation while improving ease of use.

-

O&M

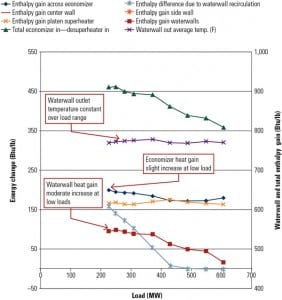

Increasing Generation Ramp Rate at Morgantown Generating Station’s Coal-Fired Units

At Morgantown Generating Station, plant personnel used innovative methods to combine model predictive control with distributed control system–based process control algorithms to improve waterwall temperature control and main steam temperature control and to enhance unit ramp rate capability. The previous heat rate and NOx optimization performance gains were retained. Focusing beyond basic loops of feedwater, air, and O2, the project considered issues such as PID controller override configuration and limitations. The techniques used to overcome these challenges improved unit ramp rate capability beyond any previous unit performance.

-

Nuclear

I&C Update on Plant Vogtle Units 3 and 4

Development of Vogtle Electric Generating Station Units 3 and 4—the first new nuclear power plant units in the U.S. in decades—has generated considerable excitement. The next generation of nuclear plants, represented by these units, includes at least two major improvements: the use of passive safety systems and a reliance on digital control systems. The latter represents a gigantic leap in modernization and a fundamental change in control of the plant.

-

O&M

New Tools for Diagnosing and Troubleshooting Power Plant Equipment Faults

The Electric Power Research Institute has developed a pair of diagnostic tools that combine and integrate features from multiple sources of plant information. The Diagnostic Advisor and the Asset Fault Signature Database will improve diagnostics for and troubleshooting of equipment faults by providing a holistic view of the condition of plant equipment.

-

Gas

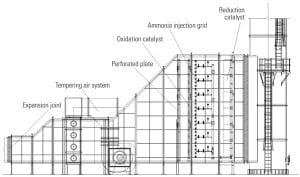

Automated Exhaust Temperature Control for Simple-Cycle Power Plants

A common concern for gas turbine power plants is treating exhaust gases to comply with laws restricting pollutants present in the gases that are emitted into the ambient atmosphere. The challenge for designers is to control the exhaust gas operating temperature within a range that maximizes performance of the oxidation and reduction catalysts.