Coal

-

Coal

Alstom’s chilled ammonia CO2-capture process advances toward commercialization

Carbon dioxide emissions aren’t yet regulated by the EPA, but it’s likely they will be soon. There are many technically feasible, but as-yet-undemonstrated ways to reduce the considerable carbon footprint of any coal-fired plant, whether it uses conventional or unconventional technology. One promising approach to removing CO2 from a plant’s flue gas uses chilled ammonium bicarbonate to drive the separation process.

-

Coal

Accelerating the deployment of cleaner coal plants

The dearth of commercial operating experience for advanced coal-fired facilities is forcing their early adopters and builders to use long development cycles and pay high costs for unique engineering design studies. A broad-based industry collaborative effort fostered by EPRI to address this issue is beginning to show results.

-

O&M

Who’s doing coal plant maintenance?

POWER has reported on several EUCG benchmarking studies over the past several years. This month we examine the maintenance staffing of 45 coal plants reported by 13 EUCG member utilities. If you benchmark your plants or fleet, as you should, some of the study’s results challenge what is considered conventional wisdom.

-

Commentary

What Congress can learn from Google

Chances are good that legislation to “cap and auction” greenhouse gas (GHG) emissions will become law as early as 2009. While many environmentalists, utilities, and energy companies agree that cap and auction is the right framework, huge differences remain. Environmentalists want an 80% reduction of GHG emissions by 2050, or sooner. Energy companies want more […]

-

Coal

Global Monitor (February 2008)

FutureGen picks Mattoon, Ill./Duke applies for first greenfield COL/PPL to work with UniStar on another COL

/Areva seeks NRC certification of its reactor/Mitsubishi also in line at the NRC/PV project shines in Nevada/SunEdison commissions Colorado PV plant/Big concentrating solar plant proposed/Super Boiler celebrates first anniversary/Small fuel cell uses JP-8 jet fuel/POWER digest -

O&M

Focus on O&M (February 2008)

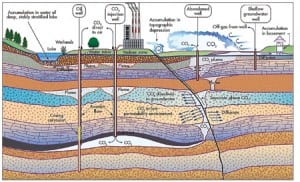

Survey captures industry’s carbon concerns; Sequestering coal plant emissions; Comparing mercury measurement methods

-

Coal

Global Monitor (January 2008)

Dominion applies for new Virginia reactor / ABB commissions world’s largest SVC / Google Earth adds air quality data / Alstom supplies integrated solar/CC project in Morocco / DOE updates coal plant database / Dam the Red Sea? / Complying with CWA Section 316

-

Coal

Regulatory risks paralyzing power industry while demand grows

In our second annual report on the state and future of the U.S. power generation industry, we combine the considerable experience of POWER’s editorial staff with the market savvy of Industrial Info Resources Inc. (see next story) to preview the industry’s direction in 2008. We anticipate that the specter of carbon control legislation will hobble coal and make renewables the hot ticket while nukes continue to inch forward in a generation market that is basically treading water.

-

Coal

Greater fuel diversity needed to meet growing U.S. electricity demand

Industrial Info Resources’ strengths are tracking capital projects and cost projections and providing intelligence about the power generation market, among others. IIR has used its large industry databases and numerous industry contacts to develop its outlook for 2008. Here’s what you should expect and plan for this year.

-

Coal

Speaking of Coal Power: With Chaos Comes Opportunity

Combat veterans use the phrase "fog of war" to explain why carefully prepared battle plans are quickly overwhelmed by chaos once the first bullet is fired. Survivors often describe experiences that are markedly different from those of others standing only yards away. The fog of our industry’s battle to build new generating plants permeates the […]

-

Coal

The Coal Patrol: Growth in PRB Coal Use Will Be Fueled by New Projects

Production from Wyoming Powder River Basin (PRB) coal mines ended last year with a increase of only about 1.1%, reflecting a record 451.3 million tons, according to the Department of Energy’s Energy Information Administration. Production of PRB coal spiked with a record 10% growth in 2006 following two derailments on the PRB’s main triple-track line […]

-

O&M

The Coal Patrol: Court Rejects Industry Suit Targeting Miner Safety Rules

A federal appeals court has rejected a National Mining Association (NMA) suit seeking to throw out new regulations issued by the Mine Safety and Health Administration (MSHA). The rules were to improve protection for miners in the wake of accidents at two West Virginia coal mines in January 2006 that killed 15. (See COAL POWER […]

-

Coal

Tech Notes: Giving PRB Coal the Respect It Deserves, Part 1

Use of Powder River Basin (PRB) coal for power generation set another record in 2007. In fact, PRB coal now accounts for about 40% of all the coal fired in the U.S. to produce electricity. Yet we have barely dented the estimated 800 billion tons of the fuel’s proven reserves in Wyoming. The size of […]

-

O&M

Coal Plant O & M: Condition Monitoring Cuts Mirant Mid-Atlantic’s Costs

Condition monitoring (CM) has become an increasingly important aspect of power plant maintenance philosophy. Today many utilities are using a variety of predictive maintenance (PM) techniques like CM to lower their operation and maintenance expenses. Over the years, gencos have developed a diverse collection of CM programs of various breadth, depth, and formality. All are […]

-

Coal

FutureGen: FutureGen Finds a Home But Can’t Pay the Mortgage

The FutureGen Industrial Alliance Inc. selected Mattoon, Ill., as the site of the $1.8 billion FutureGen project just before Christmas, but the plant may never move off the drawing board.. FutureGen, the proposed prototype of a near-zero-emissions coal plant, is to demonstrate advanced technologies for coal gasification, electricity production, emissions control, CO 2 capture and […]

-

Coal

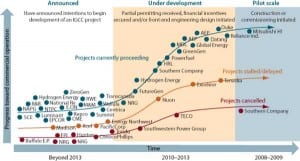

IGCC: IGCC’s Future Hinges on a Workable Carbon Framework

Integrated gasification combined-cycle (IGCC) technology, a process of gasifying coal that allows the capture of carbon dioxide emissions, has tremendous potential for meeting future baseload generation demand. Though it is one of the leading alternatives for producing clean power from coal, IGCC faces a precarious future due to rising capital costs and regulatory uncertainty. We’re […]

-

O&M

Safety: Worker Health and Safety Now Top Priorities for Alabama Power

Employees of Alabama Power, a Southern Company subsidiary, routinely work near energized wires, intense heat, nuclear fuel, heavy equipment, moving vehicles, and pressurized equipment, as well as under other conditions that require exceptional safety attitudes and measures. Though it is vitally important to provide electricity to customers, neither company believes that doing so is worth […]

-

Coal

Global Monitor (November 2007)

NRG applies for first COL / TVA green-lights Watts Bar 2 / Southern Co. and Florida muni launch IGCC project / UK approves wave energy "hub" / New Jersey-New York HV system launched / Membrane strips CO2 from methane faster / POWER digest

-

O&M

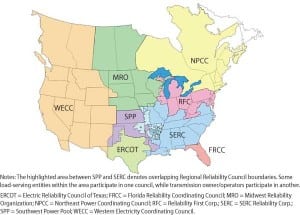

The Coal Patrol: Demand Growth — and Reliability — Are Still Supply-Limited

While noting marginal improvements since last year, America’s power reliability watchdog recently warned that the nation’s growing thirst for electricity will still far exceed planned increases in generation capacity over the next 10 years, and that reserve margins could dip below optimal levels within two or three years in California, the Rocky Mountain states, New […]

-

Coal

Advanced Combustion: Cofiring Coal and Biomass or Non-Recyclable Waste

Burning biomass or nonrecyclable commercial, municipal, or industrial waste along with coal represents one of the nearest-term and lowest-cost options for reducing carbon dioxide (CO 2) emissions from existing utility power plants. At more than 150 plants worldwide, doing so has produced lower CO 2 emissions than burning coal alone. Indeed, with the number of […]

-

Coal

The Coal Pile: Dreaming of a Green Christmas

On November 20, New York City Mayor Michael R. Bloomberg and top executives of the real estate company Tishman Speyer announced several energy conservation measures to be implemented at Rockefeller Center this holiday season. One is the outfitting of its famous Norway Spruce Christmas tree with 30,000 light-emitting diodes (LEDs) strung on five miles of […]

-

Coal

Coal Plant O&M: Retrofit Flyash-Handling System Pays Dividends

Like many older coal-fired plants, Westar Energy’s Jeffrey Energy Center (JEC) was built with traditional, pneumatic flyash-handling and removal systems. Such systems collect flyash in hoppers attached to the bottom of a unit’s electrostatic precipitator (ESP) and/or baghouse. Periodically, the hoppers are emptied into tanks and the flyash is conveyed away for disposal or beneficiation. […]

-

Coal

Safety: Detecting Fires on PRB Coal Conveyors

All conveyor systems are at risk of fire caused by the ignition of transported materials or equipment failure. But the propensity of Powder River Basin (PRB) coal to self-ignite introduces an exceptional hazard requiring special fire prevention and automatic detection and suppression efforts. To that end, this article discusses the technologies of linear heat detection […]

-

Coal

Speaking of Coal Power: Polar Bear Politics

During his June 2007 speech to the National Press Club, presidential candidate and former U.S. Senator John Edwards called America’s 37 million residents living below the poverty line "the great moral issue of our time." He proposed setting a national goal of ending poverty in 30 years. The Heritage Foundation, a conservative think tank, disputed […]

-

O&M

Tech Notes: Intelligent Sootblowing Needed to Keep Uprated Units Clean

The National Coal Council estimates that 40,000 MW of additional generating capacity is available to existing U.S. coal-fired plants simply by making efficiency improvements. Because decreases in production costs go straight to a plant’s bottom line, efficiency projects usually have short payback periods, especially if implemented in concert with mandatory environmental upgrades. One often-overlooked consequence […]

-

Coal

Pleasant Prairie Power Plant Air Quality Control Upgrade Project, Pleasant Prairie, Wisconsin

We Energies’ Pleasant Prairie Power Plant is a good example of how existing plants retrofitted with NOx and SO2 removal systems benefit from early planning and action. P4, as everyone calls it, recently completed a multiyear project to add a selective catalytic reduction system to one of its two units and a scrubber to both. The unique design and contracting aspects of the project make Pleasant Prairie one of POWER’s top coal-fired plants of 2007.

-

Coal

Polk Power Station Unit 1, Mulberry, Florida

Ten years ago, POWER selected Tampa Electric’s 250-MW Polk Power Station and its revolutionary integrated gasification combined-cycle demonstration project as the magazine’s 1997 Plant of the Year. Although no new commercial IGCC projects have been built since then, interest in deploying the coal-gasification technology is getting traction in some parts of the U.S. In 2007, POWER recognizes Polk Unit 1 as a Top Plant for developing trailblazing O&M practices and technical improvements that enable it to operate today as reliably as a modern pulverized coal plant, with lower pollutant emissions.

-

Coal

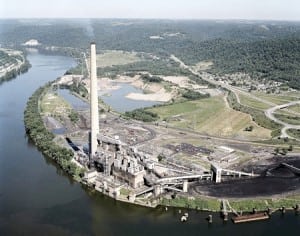

R.E. Burger Plant, Shadyside, Ohio

FirstEnergy’s R.E. Burger Plant has hosted a number of R&D projects over the years, but none as large as the demonstration of Powerspan’s 50-MW Electro-Catalytic Oxidation (ECO) multipollutant removal process a few years ago. Credit Powerspan for scaling up the demo unit and for adding CO2 as a target of a new pilot process called ECO2. And don’t forget the behind-the-scenes support of Burger’s plant staff and their willingness to incubate R&D projects while producing power. That’s what makes R.E. Burger a Top Plant in our book.

-

Coal

Managing air to improve combustion efficiency

The average pulverized coal–fired coal plant is more than 30 years old and has a heat rate in the neighborhood of 10,300 Btu/kWh operating with an "off-design" coal. Add a high load factor (or increased cycling service), squeezed maintenance budgets, reduced plant staff, and increased time between overhauls to meet the plant’s pro forma, and you’ve got major stress. Fortunately, there is a way to come in under your NOx budget and lower the stress. Breathe deeply and read carefully.