Boilers are all around us. From home water heating to massive industrial applications, they are everywhere. This article covers boiler basics, including the basic types of packaged boilers and their thermal configurations.

A case could be made for how the boiler ignited the industrial revolution by directly heating water with a flame to produce the steam used in the earliest engines. That concept remains essential across the industrial spectrum today, where the primary uses of boilers are in heating, power generation, and a wide range of manufacturing operations, food processing, and pharmaceuticals.

What Is a Boiler?

Also called a steam generator, a boiler is basically an apparatus that converts liquid into a vapor. In the vast majority of cases, it is water that is converted into steam. There are other types of boilers that use different fluids, but they are specialized applications. Boilers consist of:

- ■ A furnace or combustion zone.

- ■ Surfaces to transmit heat from the combustion products to the water.

- ■ An area where steam can form and collect.

The combustion zone or furnace is where heat is introduced to the boiler. This is often accomplished by a direct-fired unit equipped with a burner mounted in the combustion chamber that uses a mixture of fuel and air to fire directly into the boiler. Alternatively, the heat source can be a high-temperature exhaust stream from a gas turbine, thermal oxidizer, or some other process with a high-temperature exhaust, such as you might find in a refinery or chemical plant. The heat from the combustion zone is transferred to the water through tubes creating steam and the steam collects inside of a drum connected to the boiler.

General Boiler Classification

Boilers are classified in several ways. This is sometimes done based on their intended purpose. Thus, you hear about boilers for marine, institutional, light industrial, heavy industrial, utility, and cogeneration. Others classify boilers based on whether they are packaged in the factory, field erected, or of modular construction. Field erected boilers are slowly being replaced by package boilers, which can now be built on a much larger scale than in the past. For very large units, sections are built in modules for ease of transportation with final assembly done onsite.

More commonly, boilers are grouped according to their thermal configuration. Hence, you hear them defined as either being direct-fired boilers or waste heat boilers (often referred to as a heat recovery steam generator [HRSG]). Perhaps the simplest method is to split them into two basic groups: firetube and watertube.

Firetube Boilers

Firetube boilers (Figure 1) are by far the most popular type of boiler across the world. They are available in a wide variety of commercial shapes, sizes, and applications. A firetube boiler is typically considered to be a commercial boiler; whereas, watertube boilers are generally found in heavy industry. In large industrial applications, therefore, watertube models dominate.

|

|

1. A firetube waste heat boiler with elevated drum during fabrication. Courtesy: Rentech Boiler Systems |

Firetube boilers, as the name implies, have hot gas traveling through vertical or horizontal tubes surrounded by water. The water is heated through thermal conduction via the tube walls. Once it gets hot enough, it produces steam. The steam is fed to an outlet to be used in various processes. The exhaust gas is released through the stack.

Firetube boilers are typically cheaper than watertube boilers, and easier to clean, maintain, and operate. However, they are limited in capacity and pressure, and cannot provide superheated steam.

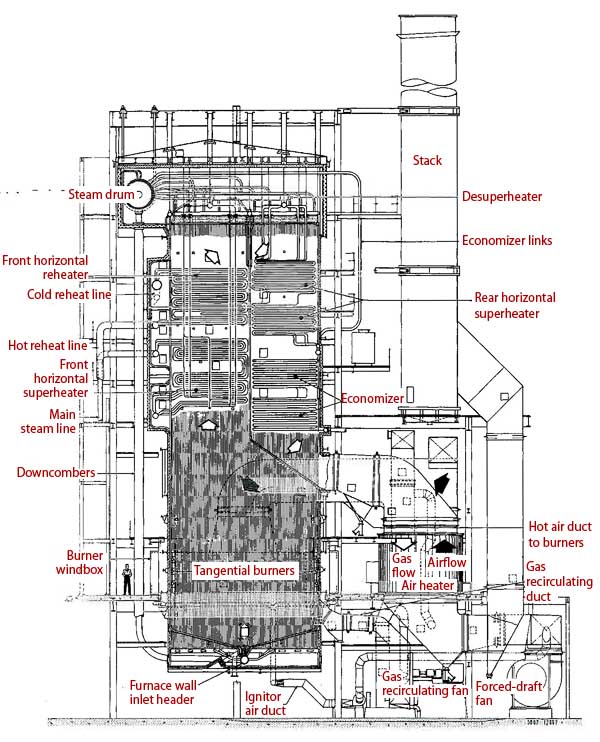

Watertube Boilers

A watertube boiler (Figure 2) has water circulating inside tubes that are heated externally by combustion gases. Hot gases in the furnace heat the water in the tubes, which rises into a steam drum. Saturated steam can then be drawn from the top of the drum. The advantages of watertube boilers include safety, longevity, and size. They are available in much larger sizes than firetube boilers and can handle much higher pressures and temperatures with the use of superheaters. In addition, the internal configuration of watertube boilers allows for better control of load swings with greater precision.

|

|

2. A large Rentech packaged boiler being transported to a site. Courtesy: Rentech Boiler Systems |

Watertube boilers are especially common in large industrial applications such as power generation, petrochemicals, and oil refining. They can use a variety of fuels including natural gas, refinery gas, hydrogen, and oil. They are generally rated based on their production in terms of pounds per hour (PPH) of steam. Utility boilers can be designed to produce millions of pounds of steam per hour; operate on solid fuels such as coal and biomass; and can produce pressures in excess of 3,000 psig (supercritical). For the purposes of this article, we will be discussing packaged watertube boilers with steam capacities as high as 650,000 PPH and pressures up to 2,000 psig. The pressures or capacities of even the largest firetube boilers don’t come anywhere close to that.

Boiler Thermal Configurations

Boilers can also be classified based on their thermal configurations. This separates them into: packaged and field erected boilers, heat recovery steam generators (HRSGs), and waste heat recovery boilers (WHRBs).

Packaged Boilers. Packaged boilers, as the name implies, are fully assembled in a factory before being shipped to a site. Depending on the customer’s needs, the boiler manufacturer will determine the maximum capacity available that can be shipped as a fully assembled unit. Limitations in road travel and rail access are often the determining factors on whether a package boiler can be provided, or if multiple smaller packaged boilers will be needed.

Field-Erected Boilers. Field-erected or stick-built boilers are constructed at the site from a series of individual components. This is done at times when they are too large to transport as an entire assembly. Sometimes their components require special transportation and lifting considerations because of their dimensions and weight. Field-erected boilers are slowly being replaced by package boilers, which can now be built on a much larger scale than in the past. For very large units, packaged boiler sections can often be built in modules for ease of transportation with final assembly done onsite.

|

|

3. A waste heat recovery boiler connected to a fluidized bed combustor. Courtesy: Rentech Boiler Systems |

Waste Heat Recovery Boilers. While many boilers are direct-fired, others harness a heat source from somewhere else, such as a thermal oxidizer, fluid catalytic cracking (FCC) unit, or some other process with a high-temperature exhaust, such as you might find in a refinery or chemical plant. The heat from this exhaust is ducted to a boiler (Figure 3) where it is used to produce steam for the facility.

HRSGs. Perhaps the most common waste heat boiler is the heat recovery steam generator (HRSG) found in a combined cycle facility. The exhaust heat from the gas turbines is fed into the HRSG where a large amount of steam is generated and directed into a steam turbine to boost the efficiency of the plant. Some HRSGs may include duct burners, which can supplement the heat of the turbine to produce more steam.

Package Boiler Types: A, D, and O

Within the packaged watertube category, there are several configurations to choose from. The most common kinds of packaged boilers are A-, D-, and O-Type boilers. Their classification is based on how the drum and burner are positioned.

A-Type boilers have one steam drum and two mud drums. They are known for their narrow furnace and low draft loss. A-type boilers are typically used in specialty applications and are the least common of the package boilers.

D-Type units are named due to their offset configuration. They are by far the most common kind of watertube boilers, accounting for more than 70% of those installed in industrial applications. They are designed with a large furnace, which helps to lower emissions while adding to the longevity of the unit. They are often specified for larger capacities (up to 650,000 PPH). Their superheater can be designed to be entirely convective, which also contributes to a longer lifespan.

O-Type boilers generally have a smaller footprint and can be engineered with a radiant superheater, if necessary. O-type boilers are especially popular with rental companies as they can be built with an integral trailer and are more easily transported by truck.

Commercial vs. Industrial Boilers: Understanding the Divide

There are many ways to classify boilers. It can be done based on their intended purpose, how they are made, and their thermal configuration. But the most basic mode of classification is into two camps: firetube and watertube.

Firetube boilers are used in commercial applications. They are relatively cheap, and easy to clean, maintain, and operate. However, they are limited in capacity and pressure; and cannot provide superheated steam.

For industrial applications, however, watertube boilers are the norm due to their versatility and scale. That’s why you find them in power plants, in chemical facilities, and in oil and gas applications.

—Drew Robb (drewrobb@sbcglobal.net) has been a full-time freelance writer for more than 25 years specializing in engineering and technology.