Project Pele, the Department of War’s (DOW’s) first-of-its-kind transportable nuclear microreactor prototype, has received its tri-structural isotropic (TRISO) particle fuel at Idaho National Laboratory (INL), where formal system testing is slated to begin as early as 2027. The fuel—manufactured by BWXT Technologies (BWXT) and shipped from its Lynchburg, Virginia, facility—represents the first TRISO microreactor fuel delivered at its final destination and builds on more than two decades of TRISO fuel development and qualification work.

BWXT’s Specialty Fuels Fabrication Group completed fabrication and shipment of the 40,000 TRISO fuel compacts from its Lynchburg facilities to INL’s Transient Reactor Test Facility (TREAT) on Nov. 5, completing a key prerequisite for the forthcoming demonstration phase. Site construction is already underway, having kicked off in September 2025.

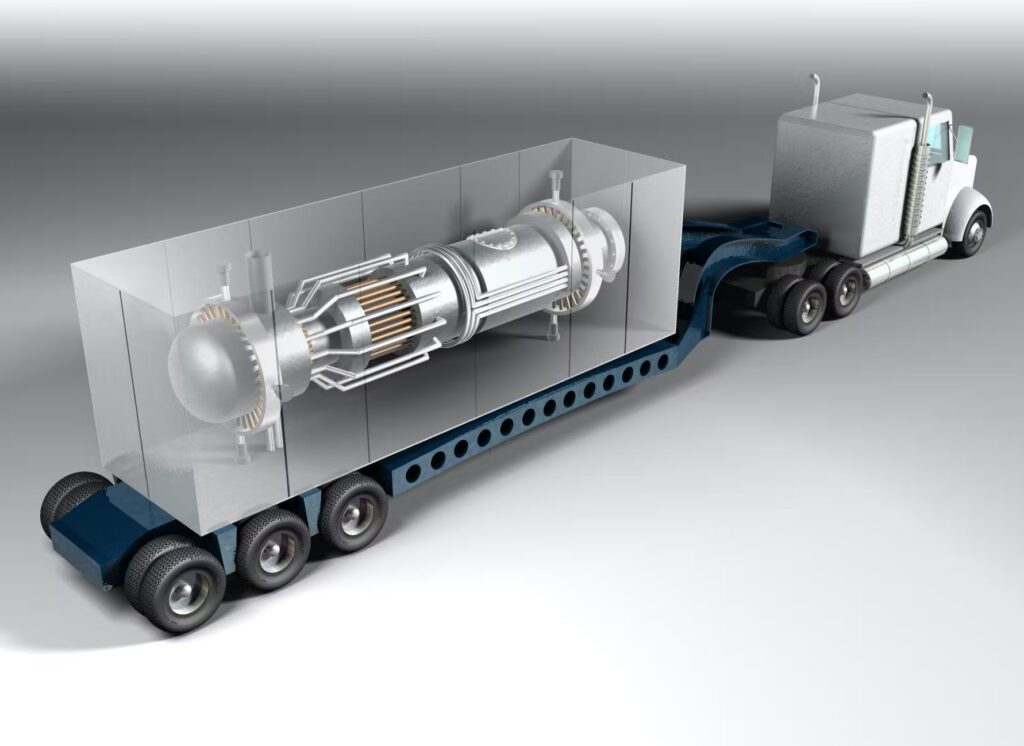

Project Pele, developed under a DOD Strategic Capabilities Office (SCO) initiative, aims to build and demonstrate a high-temperature gas-cooled (HTGR) mobile microreactor manufactured by Lynchburg, Virginia–headquartered BWXT Advanced Technologies. Fueled with TRISO particle fuel, Project Pele will produce 1 MWe to 5 MWe for INL’s Critical Infrastructure Test Range Complex (CITRC) electrical test grid for about three years.

However, the Pele prototype is still currently under construction at BWXT’s Innovation Campus in Lynchburg, where the company and industry partners Rolls-Royce LibertyWorks, Northrop Grumman, and Torch Technologies are assembling reactor, power-conversion, and control-system modules. The completed transportable system—designed to be housed in four standard-sized shipping containers—is scheduled to be transported to INL in 2026, and formal system testing is planned to begin as early as 2027.

On Nov. 5, 2025, the U.S. marked a major milestone in advancing mobile nuclear energy: the delivery of 40,000 TRISO fuel compacts to Idaho National Laboratory’s Transient Reactor Test Facility, as INL notes in this video. “The step moves Project Pele closer to its goal of demonstrating a mobile microreactor by 2028. Watch as precision handling, advanced fuel technology, and strategic partnerships come together to shape the future of nuclear innovation.” Source: INL

The milestone was widely celebrated. “This is real nuclear microreactor fuel delivered at its final destination, rather than some letter or memorandum promising to make fuel at a later date,” noted Dr. Jeff Waksman, principal deputy assistant secretary of the Army for Installations, Energy and Environment. “Project Pele is a transformational leap toward Gen-IV nuclear power,” he said.

Project Pele’s immediate payoff will likely be for the Army’s October 2025–announced Janus Program, which will “follow on to deliver affordable, reliable, commercial nuclear power to ensure that our critical infrastructure has the power they need, whenever they need it, even if the electric grid is disrupted,” Waksman said.

The Janus program, formally launched as a next-generation nuclear power effort to deliver “resilient, secure, and assured energy” for national defense installations and critical missions under Executive Order 14299, directs the DOW to commence operation of an Army-regulated reactor at a domestic installation by Sept. 30, 2028. Janus will use a milestone-based contracting model, in partnership with the Defense Innovation Unit, to build commercially owned and operated microreactors and model its approach on NASA’s Commercial Orbital Transportation Services program, leveraging Army and DOE oversight of safety, the fuel cycle, and supply chains. While it will build on “lessons learned from Project Pele,” Waksman has pledged to personally oversee the program, saying Janus “is going to deliver real hardware, not PowerPoint slides” as the Army moves “at lightning speed to make next-generation nuclear power a reality.”

Pele: From Concept to Demonstration reactor

Fuel delivery to Project Pele marks a substantial notch for a program that began in 2016, after a Defense Science Board study flagged the Department of War’s (then Department of Defense’s) need for a mobile, reliable, resilient power source that could cut fuel logistics as battlefield energy use climbs. The study identified nuclear power as the solution, and the Strategic Capabilities Office (SCO) moved forward with a full-scale high-temperature gas-cooled (HTGR) mobile microreactor concept designed to supply 1 MWe to 5 MWe for about three years at INL’s CITRC electrical test grid.

Following a two-year reactor design competition that began in March 2020, the SCO considered two engineering designs from BWXT Advanced Technologies and X-energy’s Mobile Nuclear Power Plant. In April 2022, after completing the National Environmental Policy Act (NEPA) process and issuing a Record of Decision, the DOW formally opted to proceed with Project Pele. The SCO in June 2022 picked BWX Technologies’ HTGR-based design for the prototype, and in September 2023 exercised a one-year contract option for X-energy to keep advancing its own mobile design in parallel.

The DOW broke ground at INL on Sept. 24, 2024, where the transportable reactor will be placed for testing in 2026. The assembled configuration will use four 20-foot ISO containers—housing the reactor, an intermediate heat exchange module, a control module, and a power conversion system module—positioned inside a concrete shield structure at CITRC and tied into INL’s specialized electric microgrid. Under an agreement between the DOW and DOE, Project Pele will be tested and operated under DOE authorization at INL, with the Nuclear Regulatory Commission providing input through its Advisory Committee on Reactor Safeguards as part of a broader microreactor transportation framework.

A Major Triumph for TRISO

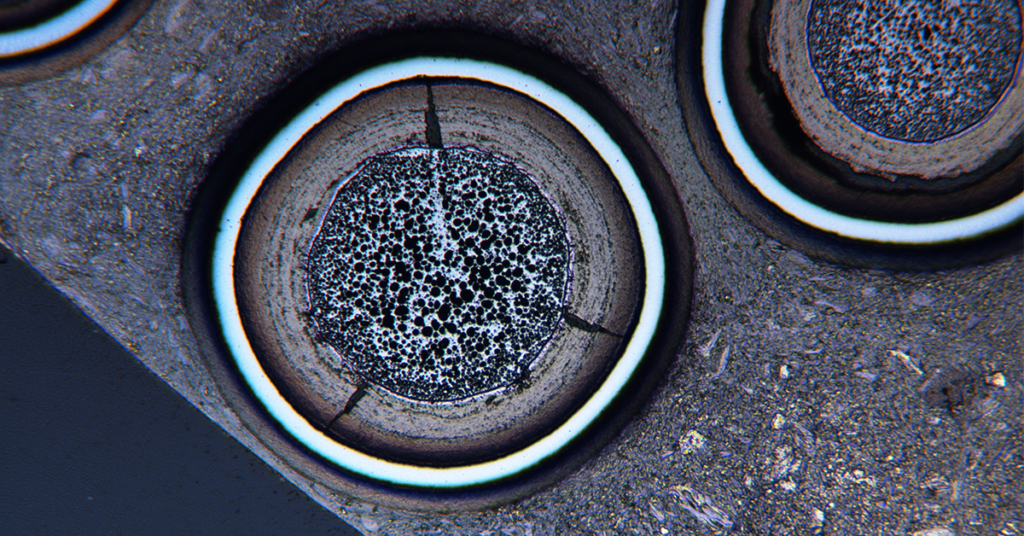

However, the milestone is just as significant for TRISO development. While the concept of coated-particle fuel for gas-cooled reactors dates to the early 1950s, the first practical demonstrations began in 1960 in the Dragon Reactor (UK), the Arbeitsgemeinschaft Versuchsreaktor (AVR, Germany), and Peach Bottom Unit 1 (Pennsylvania). TRISO’s modern tri-structural architecture—with its uranium oxide or uranium oxycarbide kernel surrounded by successive layers of pyrolytic carbon (PyC) and silicon carbide (SiC)—evolved over the 1970s in response to early coating failures and performance challenges. By the 1980s, particularly through German work with low-enriched uranium (LEU) fuel, TRISO had been refined into a robust design capable of achieving extremely high-quality fabrication and low defect fractions.

Each modern TRISO particle, roughly the size of a poppy seed, functions as a miniature pressure vessel, capable of retaining fission products even under extreme accident conditions—withstanding temperatures exceeding 1,600C without melting or releasing gaseous inventory for hundreds of hours.

Project Pele’s fuel delivery, notably, validates decades of U.S. government investment in TRISO qualification. The DOE’s Advanced Gas Reactor (AGR) Fuel Development and Qualification Program, initiated in 2002 at Oak Ridge National Laboratory and Idaho National Laboratory, established the technical basis for licensing TRISO fuel in new reactor designs and, critically, reduced market-entry risk for commercial TRISO suppliers by demonstrating fuel performance aligned with or exceeding design specifications.

Yet TRISO’s uptake has been constrained less by its proven performance than by fuel cycle economics and market uncertainty. As BWXT’s Senior Director of Advanced Nuclear Fuels Joshua Parker explained to POWER in August, suppliers have long been stuck in a “chicken-and-egg” bind: a purpose-built Category II TRISO plant—licensed to handle higher-enriched special nuclear material under NRC physical security and material control requirements—can cost hundreds of millions of dollars and requires steady demand at ton-per-year levels, but—until recently—advanced reactor developers had not committed to clear volumes or timelines. “Fuel costs are going to always make up probably a larger percent of a microreactor or a smaller advanced reactor,” Parker said, noting that a greenfield TRISO facility only makes sense if developers collectively signal ton-per-year demand rather than “100 kilograms” at a time.

Parker noted BWXT’s coated-fuel work, including for TRISO, dates back to programs in the 1980s and early 1990s, and that for at least the past 20 years, it has been DOE’s manufacturing partner on the Advanced Gas Reactor program, manufacturing TRISO particles that were then tested in the Advanced Test Reactor at INL. That R&D work—producing fuel primarily for irradiation experiments and qualification studies—was critical in generating the data that underpins today’s NRC-approved TRISO fuel performance, he said. Project Pele pushed that R&D line into operational production mode through 2023–2025, allowing BWXT to observe and optimize its entire TRISO manufacturing system for higher throughput, greater reliability, and longer-term commercial production.

BWXT’s strategy for TRISO fuel production now centers on driving down the unit cost to ensure competitiveness for advanced reactor customers, he said. That approach is supported by investments in automation, in-situ inspection, and sophisticated, data-driven quality control throughout the production line to reduce the cost of each fuel particle. Simultaneously, BWXT is working to aggregate demand from multiple advanced reactor developers, so that any new TRISO manufacturing capacity is right-sized for actual, pooled ton-scale orders—avoiding the risks of bringing new plants online too early, at too small a scale, or underutilized.

What Is TRISO?As Joshua Parker, senior director of Advanced Nuclear Fuels at BWXT, recently explained to POWER, TRISO’s relevance is only now being fully realized, despite its decades-long development. “TRISO is not new. TRISO has been around, being developed since the 1970s,” Parker says. “It’s a particle-based fuel. It’s got a kernel of uranium. It’s got multiple coatings on the outside. And when you look at it, it’s a highly engineered fuel product that’s about the size of a poppy seed. On any bad day inside of one of those advanced reactors, that TRISO particle holds all the fission products in place.” What does this mean for reactor design and deployment? Parker stresses, “It helps you reduce the cost of the deployment of advanced reactors. It helps reduce the safety barrier around those reactors, so that we can bring those to bear in the market. And it’s really enabled these ideas of microreactors or even nanoreactors.” The revolutionary containment of fission products means that TRISO offers both strong intrinsic safety and new flexibility for advanced nuclear systems, including applications requiring high process heat and small modular footprints. The renewed interest in TRISO is being fueled by nuclear’s traditional value as a reliable power source, as well as by shifts in industrial demand and advances in allied engineering fields. “If you look at the project Dow is undergoing at Seadrift, Texas, they need industrial heat,” Parker explains. Traditional reactor designs can’t efficiently provide that kind of output, but “TRISO as a fuel form…enables you to get up that heat curve and enables an industrial heat solution.” In addition, advances in materials, Parker adds, have helped make high-temperature and flexible nuclear designs much more practical than in earlier decades. BWXT’s role in the TRISO renaissance is both foundational and forward-leaning, Parker points out. “We have been manufacturing TRISO for at least the past 20 years, as a partner with the Department of Energy and the Advanced Gas Reactor program.” The company is now investing in automating and optimizing production, investigating advanced forms like uranium nitride-based TRISO, and evaluating new facility sites to meet surging demand, he said.

|

TRISO Is Becoming an Industry

Since August 2025, BWXT has effectively shifted TRISO from a government R&D line into a commercial business platform. In late August, the company formally launched BWXT Advanced Fuels, LLC, a dedicated subsidiary to commercialize advanced nuclear fuel such as TRISO, explicitly leveraging more than 20 years of TRISO manufacturing at Lynchburg and positioning itself as a merchant supplier for the “coming wave” of advanced reactors, including SMRs, sodium-cooled designs, and HTGRs.

In September, BWXT and Kairos Power announced a collaboration to optimize commercial TRISO production for the Hermes 2 demonstration plant and future reactors, including potential joint development of a TRISO fabrication facility that would combine Kairos’s pebble capabilities with BWXT’s TRISO line and automation work at its Innovation Campus. Over the same period, BWXT commissioned a specialized chemical vapor infiltration furnace and associated equipment for uranium nitride (UN) TRISO and additively manufactured fuel forms, giving it the ability to load UN TRISO into complex geometries with higher uranium density and longer life for DOE’s Advanced Reactor Demonstration Program (ARDP)–backed BWXT Advanced Nuclear Reactor (BANR) microreactor and other Gen-IV concepts. And in parallel, BWXT has advanced siting work for a proposed NRC Category II greenfield TRISO plant, including a Wyoming concept backed by a recommended $100 million state grant and a targeted in-service date around 2030.

BWXT proposes to build a $500 million TRISO nuclear fuel manufacturing facility in Gillette. Construction of the “Category II” plant would begin about a year from now, with an in-service target of 2030, according to the Lynchburg, Virginia-based company.

Across the broader market, BWXT’s efforts are being mirrored by other emerging nuclear fuel vendors racing to stand up TRISO capacity. X-energy’s TRISO-X subsidiary began vertical construction in November on its TX-1 commercial fuel fabrication facility in Oak Ridge, Tennessee—poised to become the nation’s first Category II fuel facility in decades. X-energy is targeting NRC licensing by mid-2026 and an initial output of 5 metric tons of uranium per year to support its Xe-100 fleet.

Standard Nuclear, meanwhile, is positioning itself as the nation’s only independent, reactor-agnostic TRISO fuel supplier. The Tennessee-based company emerged from stealth in June 2025 with $42 million in venture backing, having acquired fuel manufacturing assets from now-defunct USNC. Operating a fully permitted commercial-scale facility on the former K-25 site in Oak Ridge, Standard Nuclear had booked $5 million in contracts and more than $100 million in non-binding orders for 2027 by midyear, drawing customers from both advanced reactor startups and government agencies. In August, the company won selection to the DOE’s Fuel Line Pilot Program and was tasked with expanding fuel fabrication facilities in Tennessee and Idaho by mid-2026. And in September, Standard Nuclear announced a joint venture with Framatome to leverage Framatome’s existing Richland, Washington infrastructure, with plans to commence manufacturing in 2027 and ramp to roughly 2 metric tons of TRISO fuel annually.

Federal policy is also actively accelerating TRISO deployment. The DOE in September 2025 fast-tracked conditional selections for its Fuel Line Pilot Program, naming four companies—Oklo, Terrestrial Energy, TRISO-X, and Valar Atomics—alongside previously selected Standard Nuclear for accelerated NRC licensing pathways and federal support. Executive Order 14299, “Deploying Advanced Nuclear Reactor Technologies for National Security,” meanwhile, directs the DOW to have an operational Army-regulated reactor by Sept. 30, 2028, in a bid to create an immediate demand signal for TRISO fuel.

For now, the advanced reactor ecosystem is still carefully watching Project Pele. “This milestone reflects years of dedicated effort by the Office of Nuclear Energy’s Advanced Gas Reactor TRISO Fuel Qualification Program to fabricate and qualify TRISO fuel using world-class capabilities at INL’s Advanced Test Reactor and Materials and Fuels Complex, and Oak Ridge National Laboratory—capabilities that exist nowhere else in the world,” said INL Director John Wagner. “That investment is now enabling Project Pele to move forward with the speed and confidence our national security demands to accelerate American innovation and demonstrate the leadership that will define this era of nuclear energy,” he added.

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).