Proper valves, pipes, and fittings are important for the successful operation of power generation facilities. This equipment includes products with versatile designs to establish effective joining and sealing methods, and better joint integrity, ensuring safe operation in thermal, nuclear, and renewable energy power plants. Manufacturers cite improved safety and efficiency, reductions in scheduled and unscheduled maintenance downtime, and lower installation and operating costs when promoting their products. Some of the leading manufacturers and service companies for power plant valves, pipes, and fittings are featured here.

Conval Valves Help Control Boiler, Turbine Blowdown

|

|

Courtesy: Conval |

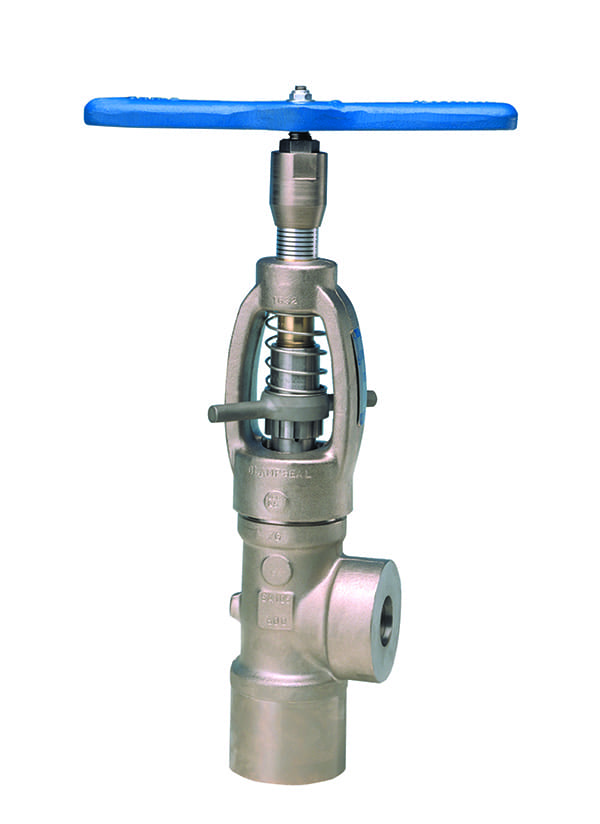

Conval offers Clampseal Blowdown Service Valves to provide necessary control for continuous or tandem boiler or turbine blowdown and bottom blow-off service. Blowdown valves are available in 3/4-inch through 4-inch sizes with butt or socket weld and flanged ends. Clampseal blowdown valves are fully serviceable in-line, using standard Conval tools. The valves feature a uniform one-piece gland, which eliminates the potential for stem damage from gland cocking. With leak-proof bonnet, the cartridge-style packing chamber allows rapid access to valve trim for inspection and maintenance. Conval, Enfield, Connecticut

conval.com

Val-Matic’s QuadroSphere Solves Application Problems

|

|

Courtesy: Val-Matic |

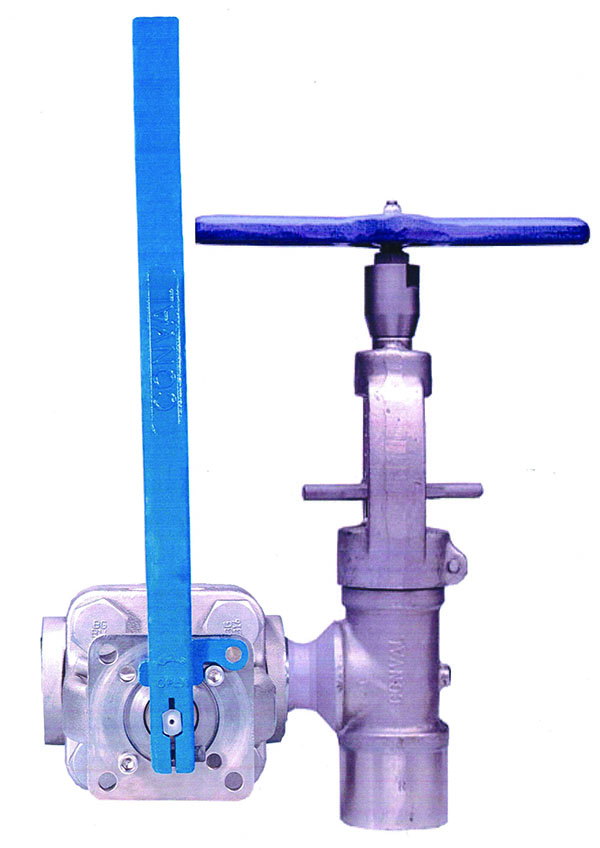

The Val-Matic QuadroSphere ball valve has more than 20 years of proven operational experience. It helps solve difficult application problems in many industries, including power generation, geothermal, and others. The QuadroSphere’s most prominent feature is the unique abrasion-resistant ball design. Four recessed surfaces of the ball provide multiple flow paths through the valve and provide for self-flushing to prevent clogging by avoiding high scale and solids build up while also protecting the seats from damage. Special machining of the ball substantially reduces the ball to seat surface contact creating less resistance during cycles, lowering the operating torque. Reduced seat engagement results in up to 70% less wear, improving the performance life of the ball and seats. Val-Matic Valve & Manufacturing Corp., Elmhurst, Illinois.

UCC Knife Gate Valve Designed for Isolation Service

|

|

Courtesy: UCC |

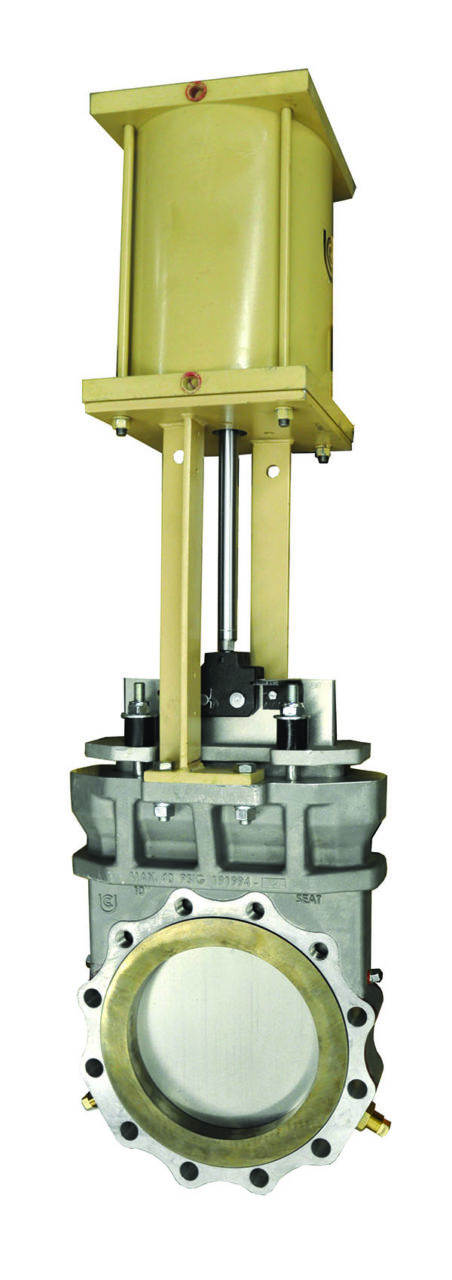

United Conveyor Corp.’s (UCC’s) 40D Knife Gate Valve is designed specifically for on/off pipeline isolation service in pneumatic conveying applications of abrasive material such as dry fly ash. UCC has taken this reliable design and incorporated several enhancements for improved sealing performance, greater reliability, and extended service life. This rugged and easy-to-maintain valve is complete with a spring-loaded packing feature that maintains seal pressure during operation to prevent leakage and extend the life of the blade and packing. The 40D Knife Gate Valve ships fully assembled to help reduce field assembly and installation costs. United Conveyor Corp., Waukegan, Illinois

uccenvironmental.com

Tru-Tech Offers Diaphragm Valves

|

|

Courtesy: Tru-Tech Valve |

Tru-Tech is an original licensee of the Arco-Wynn design. The company’s valves are available in straight-through (on-off) and enhanced-weir (throttling) designs. Tru-Tech offers diaphragm valves in MSS SP-88 (long-body) form factor, which is interchangeable with other diaphragm valves, as well as ANSI B16.10 (short-body) design, which makes it interchangeable with most solid-wedge, double-disc, and resilient-wedge gate valves as well as short-pattern plug and ball valves. The valves are well-suited for corrosive, abrasive, suspended solids, slurries, and clean service applications. Tru-Tech’s valves offer higher operating pressures (125 psig to 200 psig); zero fugitive emissions; and in-line maintenance. The valves include a double-studded diaphragm, and come in a range of valve body materials, coatings/linings, and diaphragm materials for full chemical compatibility. Tru-Tech Valve, Canonsburg, Pennsylvania

trutechvalve.com

Valves Designed to Withstand Abrasive Solids

|

|

Courtesy: Everlasting Valve Co. |

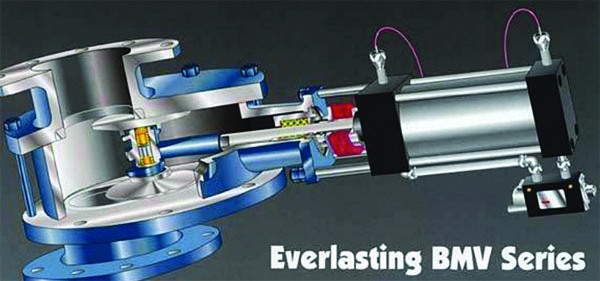

The Everlasting BMV Series of valves is designed for applications where abrasive solids are handled. The valves come in sizes from 2-inch to 12-inch; have vacuum to 100 psig; and can handle temperatures up to 550F. Everlasting valves can replace knife-gate valves, slide-gate valves, and metal-seated ball valves in power generation applications such as transporting fly ash within a plant, handling bottom ash, and handling materials for flue-gas treatment. Everlasting Valve’s bulk material valves are designed to work for years, often requiring no maintenance. They are designed to resist erosion and handle high-temperature, high-cycling abrasive fine. The valves have an innovative rotating-disc design that polishes away scratches and wipes away any particulate that has accumulated, forming an increasingly tighter seal with every pass. Everlasting Valve Co., South Plainfield, New Jersey ■