Small modular reactor (SMR) developer X-energy has secured a binding reservation agreement with South Korean power-generation equipment giant Doosan Enerbility to manufacture main power system steel components for 16 Xe-100 SMRs. As part of the decisive move to industrialize the supply chain for advanced nuclear energy, Doosan has also committed to building a new dedicated SMR fabrication facility in Changwon, South Korea, to bolster X-energy’s 11-GW commercial pipeline—”equivalent to 144 advanced reactors,” X-energy noted.

The preemptive agreement marks a substantial boost for X-energy, enabling it to secure manufacturing capacity for some of the Xe-100’s most safety-critical and longest-lead components—including reactor pressure vessels, steam generator pressure vessels, and other large steel structures. It arrives at a time when supply-chain readiness is emerging as a central constraint on the deployment of first-of-a-kind SMRs.

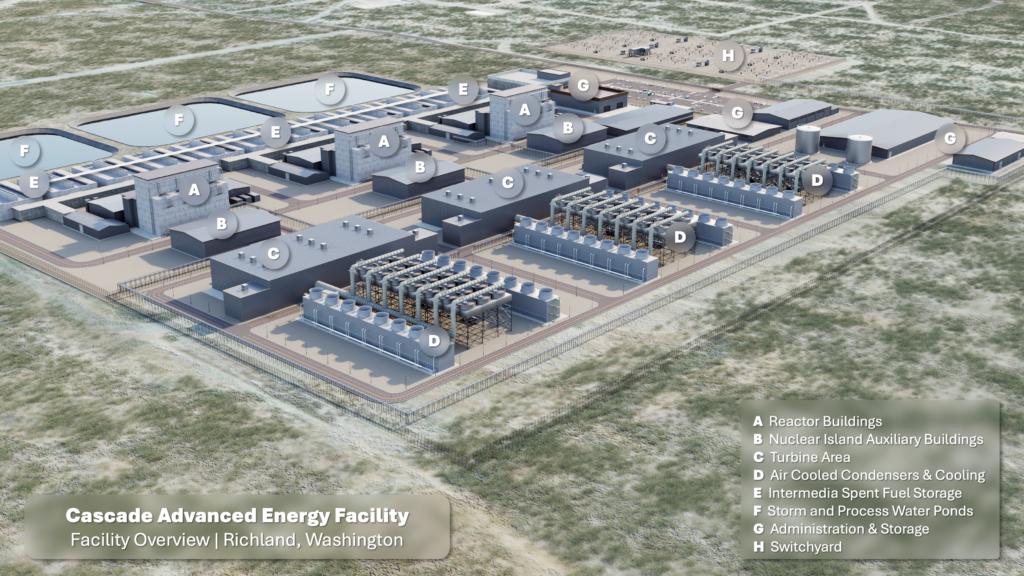

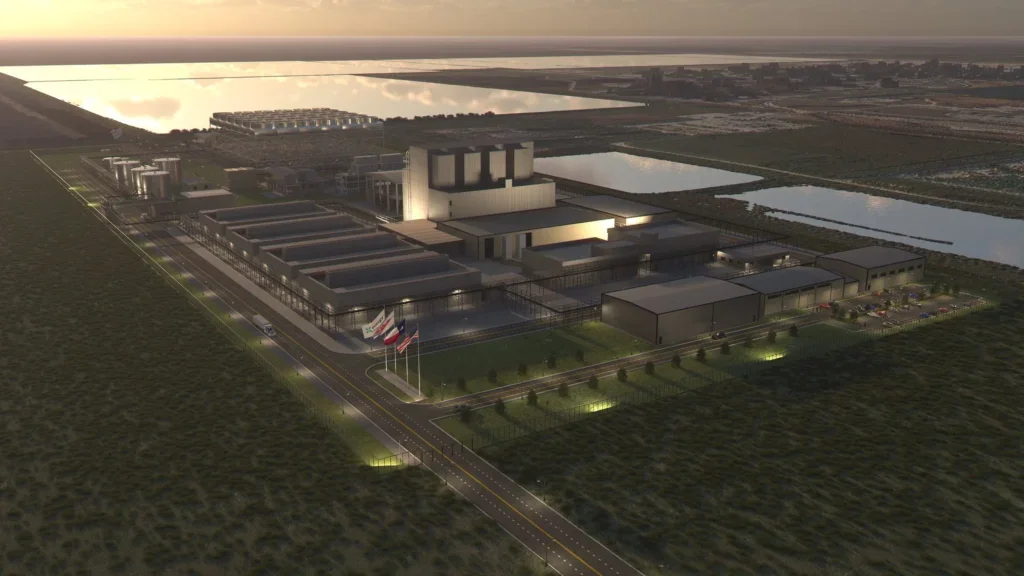

According to Doosan Enerbility, the 16 reactors covered by the reservation agreement are tied to X-energy’s initial commercial deployments, including the four-unit 320-MWe Long Mott Generating Station planned for Dow’s Seadrift Operations in Texas, and the 12-unit Cascade Advanced Energy Center proposed for Energy Northwest in Richland, Washington. The 5-GW Energy Northwest project—which X-energy is pursuing in collaboration with Amazon Web Services (AWS) and plans to deploy by 2039—is part of a larger development effort that ultimately envisions deployment of up to 60 Xe-100 reactors, Doosan said.

“By securing capacity early in the project lifecycle, X-energy’s investment is expected to enable greater cost and schedule certainty for a highly specialized long-lead component, helping to mitigate overall supply chain risk for its first projects,” X-energy said on Thursday.

Pioneering Capacity Reservations for Advanced Nuclear

Generally, in the power sector, a capacity reservation is a binding contract that secures future access to a supplier’s production capability—typically for long-lead, safety-critical components—in exchange for an upfront financial commitment. As POWER has reported, slot reservations—which are time-bound capacity reservations—have become increasingly common as demand for key equipment has outpaced manufacturing capacity. In the gas turbine market, the surge in power demand from data centers and industrial loads has triggered record backlogs at OEMs, including GE Vernova, Siemens Energy, and Mitsubishi Power. Capacity reservation agreements are also widely used in other capital-intensive industries, such as offshore wind, aerospace, and liquefied natural gas, in which vessel availability or fabrication slots can dictate overall project schedules.

However, capacity reservation agreements of this scale are rare in the nuclear sector, where suppliers have historically waited for a licensed owner, a finalized reactor design, and firm construction schedules before committing capital to new manufacturing capacity.

At the American Nuclear Society 2025 Winter Conference & Expo in Washington, D.C., in mid-November, X-energy CEO Clay Sell spoke candidly about supply chain constraints, warning that delayed action could narrow future options for project developers. “We are eventually going to run into constraints on the supply chain there that are going to limit options for those that choose to go later,” Sell said.

Sell, like others in the nuclear industry, has repeatedly championed supply-chain alignment—and repeat deployment—as a critical missing link that could bolster the future of U.S. nuclear construction. X-energy’s strategy with Amazon—which has committed to deploying up to 5 GW of Xe-100 capacity—could break the historical pattern of bespoke, one-off projects, he suggested. “With that one customer choosing one technology on three to four sites, we will get to an nth-of-a-kind cost. We will de-risk the deployment, and we will give optionality to this sector to come alongside either with Amazon or after Amazon,” he said.

Shoring up the supply chain also depends on demand signals that extend beyond the U.S. market, he noted. In September 2025, X-energy announced a joint development agreement with British utility Centrica to explore the deployment of up to 6 GW of Xe-100 capacity in the UK. The preferred first project under the agreement is a 12-unit deployment at Hartlepool, totaling roughly 960 MW. X-energy has said the project is targeting first electricity in the mid-2030s and could anchor a broader fleet-scale deployment across multiple UK sites, subject to licensing, financing, and government support mechanisms. Centrica is pursuing initial project capital to initiate full-scale development activities beginning in 2026.

X-energy has described its U.S. and UK projects as elements of a single, expanding orderbook. “We’ve always intended to have an order book that is scaling through the 2030s, towards the end of the decade, getting bigger and bigger, so that we’re able to deploy more and more reactors each year,” Benjamin Reinke, senior vice president of global business development and deputy chief commercial officer at X-energy, told POWER in September.

What the Reservation Covers

Under the binding agreement announced by X-energy on Thursday—and disclosed by Doosan Enerbility earlier on Dec. 12—Doosan will manufacture 16 complete sets of main power system components, including reactor pressure vessels (RPVs), steam generator pressure vessels (SGPVs), and associated large steel structures. Those components are central to the Xe-100 reactor design.

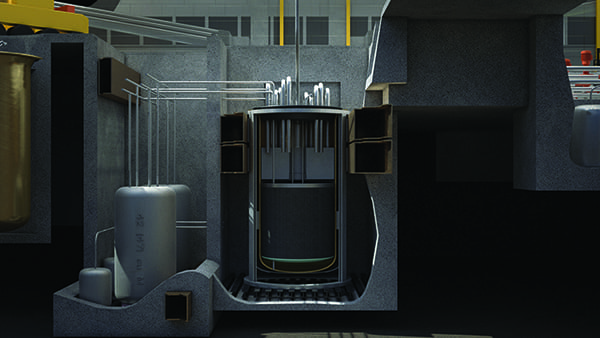

The Xe-100 is a high-temperature gas-cooled reactor (HTGR) that uses helium as its primary coolant and TRISO-coated (TRISO-X) fuel particles embedded in graphite pebbles. Each module produces about 200 MWt and is designed to operate at outlet temperatures of roughly 750C—more than twice that of a conventional light-water reactor—enabling both electricity generation and high-value industrial heat applications. Unlike water-cooled reactors, the Xe-100 relies on a large, uninsulated steel reactor pressure vessel and graphite moderation to passively dissipate heat during off-normal conditions, a design choice that places exceptional demands on the main power system hardware.

The reactor pressure vessel houses the nuclear core and TRISO-X fuel and maintains the primary helium pressure boundary under sustained high temperatures, while the steam generator pressure vessel contains the heat-exchange system that transfers thermal energy from the reactor to the secondary steam cycle. The two vessels are linked by a cross vessel and hot gas duct, which directs high-temperature helium from the reactor to the steam generator while preserving thermal efficiency and structural integrity.

“Together, these large, steel structures form the exterior and structural interior of the Xe-100, and are among the largest and most safety-critical elements of the design,” X-energy noted.

Fabricating those components requires nuclear-grade heavy forgings, specialized welding and machining, and certification under ASME Section III nuclear code requirements, factors which drive extended lead times and sharply limit the number of qualified suppliers worldwide. “By securing capacity early in the project lifecycle, X-energy’s investment is expected to enable greater cost and schedule certainty for a highly specialized long-lead component, helping to mitigate overall supply chain risk for its first projects,” X-energy added.

Xe-100 Main Power System ComponentsThe Xe-100’s main power system—the integrated assembly of reactor and steam generator vessels and their internal structures—comprises five major steel pressure-boundary structures and internal assemblies that form the core of the plant’s thermal system. Together, they house the reactor core, manage the flow of high-temperature helium coolant, and transfer heat to generate steam for electricity production or industrial process use. The pressure-retaining components are designed and fabricated in accordance with ASME Section III nuclear code requirements.

Reactor Pressure Vessel (RPV). The primary containment structure that houses the reactor core, TRISO-X fuel, and maintains the pressure boundary for the Xe-100’s helium coolant. This large steel vessel is designed to withstand high temperatures and pressures while containing the nuclear reaction and providing radiation shielding. Steam Generator Pressure Vessel (SGPV). The containment structure that houses the Xe-100 steam generator. This vessel maintains the pressure boundary for the heat exchange process, circulating high-temperature helium from the reactor core to generate steam for electricity production or industrial applications. Cross Vessel & Hot Gas Duct. The connecting piece between the Reactor Pressure Vessel and the Steam Generator Pressure Vessel. Within this cross vessel is the Hot Gas Duct (HGD), which is the insulated pathway that directs hot helium gas from the reactor to the steam generator while maintaining thermal efficiency and providing structural integrity for the connection between the two main vessels. Reactor Internals (RI). Structural components inside the reactor pressure vessel that support the nuclear fuel and helium circulation. These include components like the core barrel, core support structures, and other internal elements that ensure proper operation of the reactor. Steam Generator Internals (SGIA). Comprises the internal components of the steam generator, including heat transfer tubes and other structures that facilitate efficient heat exchange from the reactor coolant to the steam generation system. |

Doosan and X-energy’s Evolving Manufacturing Partnership

Doosan’s role in the reservation reflects a partnership that has been building for several years around manufacturability and scale. The South Korean company began collaborating with X-energy in 2021 on engineering and design to optimize the fabrication of Xe-100 components, an effort that was followed by Doosan’s equity investment in X-energy in 2023. The relationship was further formalized through a strategic collaboration agreement signed in August 2025 by X-energy, Doosan Enerbility, Amazon, and Korea Hydro & Nuclear Power (KHNP) during President Lee Jae Myung’s state visit to the U.S. The four-party MOU essentially outlines broad cooperation across reactor engineering design, supply chain development, construction strategy, and investment planning. As notably, the signatories committed to mobilizing up to $50 billion in public and private investment for Xe-100 projects by 2039.

For now, according to Doosan, “follow-up agreements on commencing the manufacturing of the SMR forgings and modules are expected to subsequently take place between the two companies.”

On Thursday, however, the company revealed it has “committed” to build a “a new, state-of-the-art SMR fabrication facility” in Changwon, South Korea to support execution of X-energy’s 11-GW commercial pipeline and meet growing global demand for advanced nuclear components. “The expansion is expected to produce new manufacturing capacity sufficient to support approximately 20 Xe-100 reactors annually at full production, with flexibility to scale based on market needs,” it noted.

Doosan has characterized the reservation as a transition from planning to execution. Jongdoo Kim, CEO of Doosan Enerbility’s Nuclear Business Group, said the agreement “represents a meaningful milestone, signaling that SMR manufacturing is entering a more advanced stage of preparation.” He added that “Doosan intends to support X-energy’s program with rigorous quality standards and reliable delivery.” In earlier remarks tied to the Dec. 12 signing, Kim said the agreement also “signif[ies] that we are now officially embarking on the manufacturing process.”

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).