The Global Energy Challenge Makes a Strong Case for Battery Energy Storage

The value of electricity has increased dramatically as a product of the global energy challenge—and this trend is unlikely to diminish. Energy providers are actively seeking ways to reduce their reliance on natural gas while also avoiding curtailment of energy from renewables.

Using batteries to store abundant energy at low prices, then selling it when prices are high (arbitrage) was not economically viable a decade ago—mostly due to the relatively high cost per installed kilowatt-hour (kWh) for a four-hour system. Besides, the renewable energy production from solar and wind could be easily absorbed by the grid.

Today, however, demand is shifting from short-term applications to more energy-focused, longer-term durations to facilitate the transition to renewables. Fortunately, battery energy storage systems (BESS) can cater to this demand through time-shifting (storing energy from peak production for later use in periods of peak demand).

As we all work toward net zero, BESS can play a critical role in capturing and valuing precious zero-carbon electricity that otherwise risks being curtailed—at an economic and environmental cost.

BESS to the Rescue

The power grid needs flexibility and capacity. The need to balance the variations of demand and supply increases with the growing penetration of variable, non-dispatchable renewable generation. It also needs sufficient capacity to deal with peak demand to guarantee supply security for several hours, particularly during cold winter evenings. The need for capacity reserves is heightened due to the unpredictable nature of renewables. Traditionally flexibility and capacity reserves are provided by fast-reacting resources like combined cycle gas turbines (CCGT). Yet, BESS offers a greener replacement to this fossil fuel–based resource.

A primary concern, however, is around the cost of BESS. While the overall cost of Li-ion battery energy storage has reduced significantly over the last decade, it has risen by 15% in the last year due to the increase in raw material costs. But it is not all doom and gloom because a reduced capacity for industrial refining, not a shortage of natural resources, was responsible. Subsequently, we have seen raw material prices decreasing again since the beginning of the year.

This means that battery energy storage has become increasingly competitive, delivering peak power at a similar cost to gas peakers. Battery solutions are already winning tenders over gas-peaking in the U.S. In the European Union (EU), BESS are now a more profitable venture than before due to soaring energy costs.

Due to the ever-increasing amount of renewable generation, we currently see a steady increase of curtailed renewable energy. The major role of storage, therefore, consists of absorbing renewable energy when produced in excess of consumption or in excess of the grid’s transmission capacity, so that no energy is lost for the community.

Increasing Digitalization

Modern BESS are also becoming increasingly digitalized, enabling real-time system management. This improves efficiency while reducing downtime and maintenance costs. Data interfacing with the cloud provides remote monitoring of key performance indicators (KPIs) and control over all operational parameters of their system.

In some newer installations, a contract might specify that the BESS must provide a minimum amount of energy, measured in megawatt-hours (MWh), at a specified availability, say 98%. With Saft’s I-Sight system, for example, the digital platform monitors performance in real-time to ensure the BESS delivers on that KPI. The platform will alert the customer and Saft of any deviations, enabling them to take immediate action.

It is also now possible to resolve most issues without ever needing a site visit, thanks to remote diagnostic and reconfiguration tools. This increased digitalization means that just 10% of cases now require a site visit. When an on-site visit is required, the time-to-repair (TTR) is reduced because the technician has foresight of the issue, so is better equipped to solve it.

Scaling Up Faster

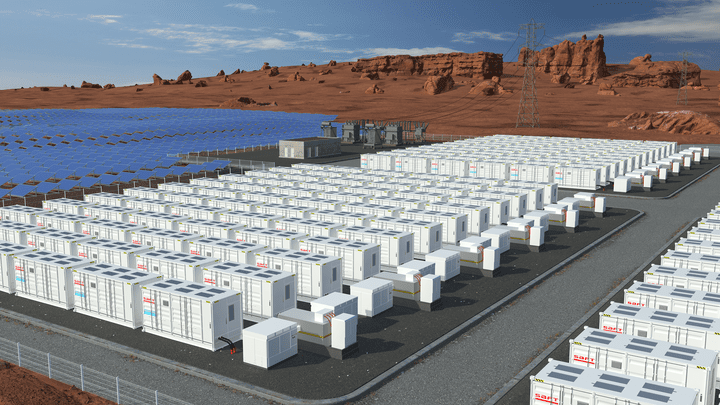

Today, systems of 100 MW are commonplace. So, installation space is becoming an increasing challenge.

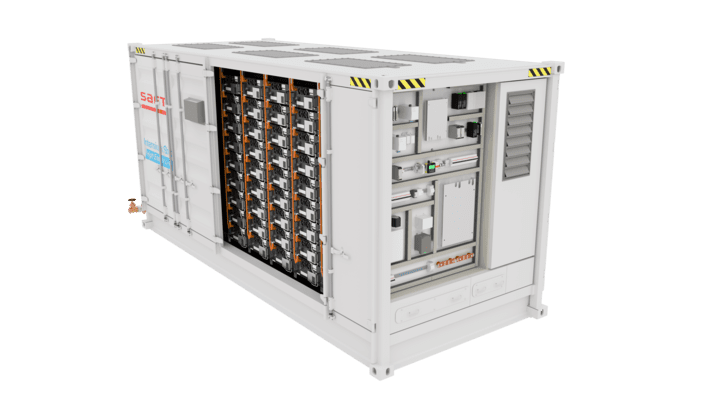

BESS energy storage capacity per container has increased, facilitating a smaller system footprint. For example, Saft’s new containers, Intensium Shift, have increased from 2.3 MWh to 3 MWh (Figure 1). This is provided by greater energy per module and an enhanced system design.

Developments in container design are also reducing footprint and installation time. For our new containers, we have now integrated the blast panels as well as the heating, ventilation, and air conditioning (HVAC) inside the container. These save about one to two hours of installation time, as previously they had to be installed on-site. If your system needs 100 containers, then the time and cost savings are significant in relation to the entire project.

Advancements in Control

One challenge that comes from increasingly large and long-duration systems is avoiding the multiple power conversion systems (PCS) needed to convert the direct-current (DC) output of several multiple containers into the alternating current (AC) required by the grid. Increasing the number of PCS at lower power rating reduces the risk of unbalanced state-of-charge (SOC) in the connected battery units. However, it leads to sub-optimized space usage—the more PCS, the more space is needed—and higher cost as smaller PCS are more expensive per MW than larger ones.

We developed the Cube control system that accurately manages up to eight containers (Figure 2) in parallel. This allows you to design system architectures based on the largest, cost-optimized PCS systems available on the market. A typical 4-MW, four-hour shifting service would involve a single string with one 4-MW PCS connected to six Intensium Shift containers (totaling 18 MWhDC). You can then replicate that setup to scale up to hundreds of MW, if required.

The increased energy density of the container building blocks, combined with advanced controls and a space-saving plug-and-play installation, is game-changing. All in all, this means the industry can now deliver utility-scale BESS for up to eight hours of energy shifting, all while halving the floorspace and installation time.

Where Now for BESS?

In contrast to the EU—where storage durations generally do not exceed an hour since the energy market is driven by grid services—shifting energy by a couple of hours is already quite common in the U.S. This is because 30% to 40% of photovoltaic (PV) solar operations already come with BESS. The Inflation Reduction Act (IRA) has increased the amount and duration of tax incentives associated with new solar farms, and solar farms with co-located storage, extending them to standalone batteries. This will further boost storage investments in the U.S.

While there was once less incentive for BESS, the tide is now turning. As we integrate more and more renewables, we must capture, store, and deploy that energy when it is needed. Otherwise, we risk wasting energy—an increasingly precious resource in today’s world.

—Michael Lippert is director of Innovations and Solutions for Energy at Saft, a subsidiary of TotalEnergies. For more information, visit https://www.saftbatteries.com.