Strategies for Operating Safely within Power Construction Zones

Temporary work zones are often required when constructing or rehabilitating power generation facilities and infrastructure. Safety is the essential factor in any industrial setting, and this is especially true when it comes to activities that disrupt normal operations. The introduction of vehicles, equipment, materials, and personnel to any environment can necessitate new strategies for keeping people safe and managing traffic flow in and around the site.

For renovation/repair projects, work zones must be created in such a way as to minimize potential hazards and the impact of construction activities on both the environment and the safety of those who might be affected. For all activities, the work zone must be set up according to the specific requirements of the project.

Steps to Safer Work Zones

Properly designed work zones will, above all, limit access to the construction site to keep disturbances to a minimum. Regular maintenance of the work area is necessary during construction, including routine inspections and enforcement of safety protocols. When setting up work zones, it is important to take a methodical approach to protecting people, property, and progress:

- Safety Planning. The first step is to create, implement, and communicate a comprehensive safety plan specific to the work activity. (No two construction projects are alike, nor are safety measures identical.) A comprehensive safety plan should be implemented prior to the start of any work and should include clear objectives, measurable goals, and a straightforward process for achieving them. Communication between all involved parties is vital to maintaining the safety of the work site. Regular meetings and toolbox talks should be held where safety protocols and procedures can be discussed, and plant personnel and construction crews should always be encouraged to speak up if they feel unsafe or have any concerns.

- Safety Training. Beyond routine workplace safety training, focused training may be required for employees in active construction zones. There are many types of work zone training programs available through organizations like the National Safety Council, Federal Highway Administration, and the National Work Zone Safety Information Clearinghouse to name a few. Courses can range from designing work zones to project coordination training to using smart technologies to improve access point safety. Employees can take courses to improve their knowledge and understanding in specific construction environments, and supervisors can track the progress of individual students to ensure that they are prepared to carry out their duties safely.

- Safety Gear. All safety equipment approved for the project should be tested and maintained on a regular basis. For example, vests, hard hats, goggles, and hearing protection should all be kept in good condition, securely stored, and regularly inspected. Additionally, personal safety equipment such as safety harnesses and lanyards should be correctly fitted. Note that American National Standards Institute (ANSI) guidelines require full-body harnesses to have “breakaway” lanyard keepers that break if any pressure greater than 120 lbs is encountered. Furthermore, for any lanyards that might be worn around the neck, this is necessary to make sure that the lanyard will snap and release to prevent injury or strangulation.

- Risk Assessment. Prior to beginning, risk assessments of the work site should be performed regularly to identify potential hazards. During any active work, a pre-job safety briefing should be conducted at the start of each day (and as shifts change) by the site supervisor to review safe practices, discuss any problems or incidents that may have occurred the previous day/shift, and to assess current conditions and known factors (such as peak traffic times, goods/materials scheduled for delivery, equipment/vehicles on-site, etc.) that might impact the work zone throughout the course of that day.

- Access Control. Also important is to put in place access control measures that ensure only authorized personnel can enter the work zone. This can be done by installing access control systems—commonly card or badge readers—at the gate or other entry points. In some cases, it may be necessary to ensure that there is only one point of entry and exit, which should be monitored at all times by a security guard and/or traffic supervisor depending on the project environment.

- Electronic Surveillance. Continued advances in wireless security technology have also made electronic surveillance more feasible and cost-effective for temporary work zones. This can include closed-circuit television (CCTV) cameras, motion sensors, and other networked devices that can monitor and detect work zone intrusions or suspicious activity. Additionally, the surveillance system may be linked to a data center allowing authorized personnel to monitor the work zone in real time.

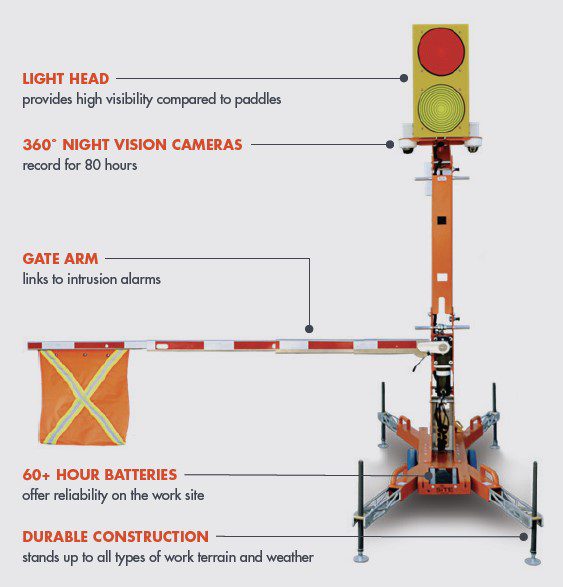

| AFADs Automated Flagger Assistance Devices (AFADs) are one example of how technology is improving work zone safety. AFADs can be monitored by a human operator standing at a safe distance or, other times, without the need for an operator to be present. These devices are equipped with sensors that detect oncoming vehicles and deploy the flagging process accordingly. This can help reduce the total cost of controlling work zone traffic, thereby making it more budget-friendly for companies with construction projects to manage.

|

Experts Can Help

It is essential to have a safe and efficient process for moving vehicles, equipment, materials, and personnel around work zones in order to quickly complete projects and avoid unnecessary delays or accidents. For this reason, power professionals, and engineering and construction firms alike, are advised to consider the assistance of a professional traffic control services provider when constructing or rehabilitating facilities and infrastructure.

Professional services providers know the ins and outs of designing safe work zones and tend to be better equipped to handle unexpected issues that may arise during the construction process—everything from the need to quickly evacuate personnel to modifying the work zone in response to changing conditions. Furthermore, by utilizing a provider who is well-versed about local laws and industry regulations, companies can reduce the risk of an unfriendly audit or fines due to noncompliance issues.

For any power related projects, it is essential for employees and officials to remain vigilant when it comes to safety. A properly planned and implemented work zone can add peace-of-mind that everyone is better protected.

—Mark Ludewig is the vice president of Safety for AWP Safety, North America’s leader in professional traffic management. Mark has more than 30 years of experience in environmental, health, and safety management, and leads AWP Safety’s ongoing enterprise initiatives to deliver the safest work zones by leveraging industry data, aligning enterprise with all-encompassing traffic control solutions, and ensuring compliance at all levels. Mark holds a master’s degree in safety engineering and management from West Virginia University and a bachelor’s degree in psychology from West Liberty University. He is a Certified Safety Professional, Safety Trained Supervisor, and Smith System Driver Instructor.

AWP Safety manages a broad range of industrial construction and rehabilitation projects requiring the use of sophisticated traffic control devices in combination with control methods administered by certified protectors. In addition, the company is responsible for the submittal of necessary plans and approvals including permitting, material estimates, and field surveys. In all cases, AWP Safety ensures that all elements of the project comply with federal and state regulations. Learn more at awpsafety.com.