POWER

-

Nuclear

Charlie Brown, nukes, and the football

The term "nuclear renaissance" is on the lips of many in the nuclear power industry today, for good reason. The federal executive branch is friendly to nukes; a nationwide shortage of baseload generation looms; the nuclear industry has vastly improved its performance in running its 20th-century plants; and a new generation of plant designs is ready for the road.

-

Coal

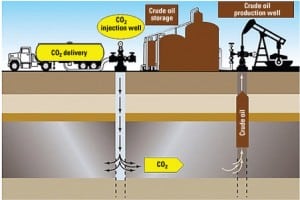

Exploring the many carbon capture options

Carbon capture and sequestration have many technical hurdles to leap in coming years. The capture and reuse of CO2 to enhance oil recovery preceded the current clamor over climate change, and that experience is often used as an example that the process is a viable way to handle this greenhouse gas. This article explores options for the first part of the process: CO2 separation and capture.

-

O&M

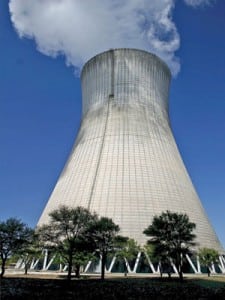

Adding cathodic protection to a hyperbolic tower

Hyperbolic cooling towers have a distinctive shape, but that form is subordinate to function—natural-draft cooling is cheaper than mechanical-draft cooling. The lower operating costs are offset to some degree by the higher cost of protecting internal tower surfaces from swings in humidity that foster corrosion damage. Learn how one utility added cathodic protection when it repaired its corroded hyperbolic tower, giving it a new lease on life.

-

O&M

Getting to the root of lube oil degradation problems

Doctors and engineers realize that solving a health problem is better done by identifying and eliminating its cause than by treating its symptoms. For machinery, the class of multidisciplinary methods known as root cause analysis (RCA) is an important tool for addressing chronic reliability problems. But RCA often is improperly applied to lubrication-related problems. Read on to learn how to use the technique correctly.

-

O&M

Utilities surpass other industries in asset maintenance practices

Want some good news about your predictive maintenance program for a change? A recent research report by the Aberdeen Group found the electric utility industry benchmarks exceptionally well against other industries in its PDM practices. In fact, the research found that best-in-class companies outperformed industry peers in improving asset availability by up to a three-to-one margin. In a web exclusive, the Aberdeen Group has provided its report for download from powermag.com as a service to our readers.

-

O&M

SO3’s impacts on plant O&M: Part III

Part I of this three-part series (POWER, October 2006) explored the negative impacts of sulfur trioxide (SO3) on the operations and maintenance of back-end plant equipment. Part II (February 2007) listed and quantified the likely and potential benefits of limiting the concentration of SO3 in flue gas to 3 ppm at the entrance to the air heater. This final part describes the characteristics of an optimal SO3 removal technology and details the operating experience of a patented process that has worked successfully at a half-dozen plants for up to three years.

-

O&M

Blades, better than new

The challenge for suppliers of aftermarket turbine blades is that their starting point is an existing blade and nothing else. There are no CAD models, drawings, measurements, tolerances, or inspection data associated with it. However, thanks to the latest in computer tools, a blade now can be digitally recreated to exact specifications and built using the latest design and manufacturing practices. Here’s an inside look at how turbine blades are captured, reconstructed, inspected, and remade to be better than the originals.

-

O&M

Practical guidelines for determining electrical area classification

A century ago, boiler explosions were an all-too-familiar event. But with the universal adoption of the ASME Boiler and Pressure Vessel Codes in 1914, explosions caused by poor design or manufacturing became relics of history. Electrical classification codes had the same effect on safety. This article explains how designers and operators practically apply those standards. Code details and samples of area classification drawings for a gas turbine plant are included in an online supplement (see end of story).

-

Gas

Balancing power and steam demand in combined-cycle cogeneration plants

The 2005 amendment to the 1978 Public Utility Regulatory Policies Act created some unique challenges for the design of cogeneration plants in general and combined-cycle cogeneration plants in particular. Because utilities are no longer obligated to buy electricity at "avoided cost" from qualifying facilities, plant owners must simultaneously balance power and thermal demand efficiently and economically. Here’s a prescription for your next plant design.

-

Business

ELECTRIC POWER Conference set for record year

ELECTRIC POWER 2007, sponsored by POWER magazine, will be presented at the Donald E. Stephens Convention Center in Rosemont, Ill., May 1 through May 3, 2007. A full agenda of preconference workshops and tutorials is scheduled for Monday, April 30.

-

News

This month in POWER …

March 1886 POWER reported on the latest development of a new and improved engine: "The chief feature of the Corliss engine [from Kendall & Roberts, Cambridgeport, Mass.] is the valve gear, which consists of four cylindrical valves, two each for admission and exhaust, operated from a central swing or stud plate; the steam valves being […]

-

Commentary

A vision for speeding up science and technology developments

As David Wojick explains in his article, "Mapping technology chaos," on page 36, power engineers are under the gun to innovate. The president and Congress are calling for dramatic new advances in power technology. They are even considering legislating progress in areas such as efficiency and emissions control. Turning data into information Power engineers know […]

-

Unequivocal bragging rights

The new congressional leadership has promised a "new" agenda for fighting climate change based on reducing the quantities and rate of growth of greenhouse gases (GHG) discharged to the atmosphere. My first question to the Democrats: Where have you been the past few years? My second: How much are you willing to spend to make […]

-

Gas

Global Monitor (March 2007)

Winter storms ravage Nebraska grid / Waste-fired plant coming to Arizona / Wartsila lands jobs in Azerbaijan, Sweden / Yet another controversial LNG project / Siemens lands two-gasifier order in China / IndyCars drink nothing but ethanol / New Otto/diesel engine to debut in Russia / POWER digest / Readers talk back

-

O&M

Focus on O&M (March 2007)

The critical subset / Aging workforce challenges / Tighter tolerances in retrofits / Writing sensible start-up and shutdown procedures

-

Legal & Regulatory

Why raising renewable portfolio standards won’t work

Almost half of U.S. states now insist that their investor-owned electric utilities serve a specified percentage of their load with electricity from renewable resources by a date certain. Utilities struggling to comply with their mandate increasingly warn that they will be unable to achieve the required level on time. Yet even as utilities express these […]

-

Water

Reclaimed cooling water’s impact on surface condensers and heat exchangers

Because water is more precious than power in many regions of the U.S., plant designers are more frequently specifying the use of treated wastewater for plant cooling. Using "gray water" poses its own challenges for critical service equipment like condensers and heat exchangers. Some problems—like corrosion—are familiar, whereas others are rare. But so far, none has been a match for the ingenuity of multidisciplinary design experts.

-

Business

Mapping technology chaos

Power engineers are in a predicament: Technology is advancing at a dizzying pace, but we are unsure how to mine information from disparate sources or predict the next big thing. Becoming expert at finding technology hones your competitive edge in both the workplace and the marketplace. Bring your pick and shovel, and we’ll show you where to start digging.

-

Business

U.S. Commercial Service helps suppliers go global

Successful exporting of goods and services is essential for U.S. companies seeking to exploit the increasingly open world economy. In the export business, the challenge is learning the ropes without getting hung out to dry when entering a potentially lucrative but unfamiliar market. Take advantage of the significant experience of the U.S. Commercial Service—its people really are here to help.

-

Water

Fish and cooling water intakes: Debunking the myths

Thermal power plants are required to use fish protection technologies or make changes in plant operation to protect aquatic organisms. We intuitively understand that some organisms in the water drawn in to cool a power plant can be injured or killed when they hit a screen or enter the circulating water system. You have options for compliance with EPA rules; some are extremely expensive and burdensome, whereas others are brilliant in their simplicity. This article debunks several fish impingement myths and gives practical advice for successful compliance.

-

O&M

Water hammer and other hydraulic phenomena

The term "water hammer" encompasses a handful of hydraulic and thermohydraulic mechanisms. They include water hammer in steam and water piping, water piston, water induction, flash condensation and evaporation, and shock waves generated by transonic flow. All can lead to failures of steam and water cycle components and put plant operators and workers at risk. Proper design and O&M practices can keep water hammer and similar phenomena under control.

-

Gas

Will turbines require expensive retrofits to handle imported LNG?

With domestic reserves of natural gas declining and demand for gas rising, imported liquefied natural gas will increasingly fill the shortfall in U.S. pipeline supply. More than 40 LNG receiving/regasification terminals on three coasts are in various stages of development. Yet many questions about the operational and emissions impacts of the "hotter" LNG imports on today’s cleaner-burning gas turbines remain unanswered.

-

O&M

Focus on O&M (February 2007)

The compliance clock is ticking / First-class maintenance in a developing country / Bypass losses squander big bucks / Revised operating procedures

-

Legal & Regulatory

The tyranny of the final, nonappealable condition

The financing of power generation projects increasingly depends on the execution of a long-term power-purchase agreement (PPA). A common prerequisite for considering a PPA to be "effective" is a "final and nonappealable" regulatory order approving it. Purchasing utilities justifiably insist on such certainty to immunize their PPAs from after-the-fact regulatory scrutiny and possible penalty. Unfortunately, […]

-

Nuclear

Arc flash protection should be job No. 1

Arc flash is arguably the most deadly and least understood hazard faced daily by plant personnel. Research indicates that even the best safety plan, training regimen, and protective equipment may be no match for the heat and blast effects of an arc flash. Consider this article a wakeup call to retrofit every switchgear cubicle in your plant with a properly designed remote racking system. Forewarned is forearmed.

-

Instrumentation & Controls

Innovative boiler master design improves system response

A quick and nimble boiler distributed control system can end up moving at the speed of molasses in winter after a low-NOx retrofit. In one utility fleet, several units—despite being equipped with a modern DCS—were experiencing firing system time lags and degraded dynamic loading capability. Swinging steam pressures and opacity excursions were forcing operators to constantly remove the unit from the load dispatch. Read how a new boiler master design read the riot act to those unruly steam generators.

-

O&M

To optimize performance, begin at the pulverizers

A systematic, performance-driven maintenance program for optimizing combustion can achieve great results. The challenge for an O&M staff is deciding which proven strategy and tactics for reducing NOx and improving plant reliability to adapt and implement. The structured approach presented here has proven its worth at several plants that have wrestled with problems similar to yours.

-

O&M

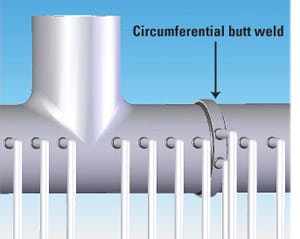

Finding and fixing cracks in high-temperature headers

The welds on superheater and reheater headers are arguably the most stressed parts of a modern steam plant. For that reason, it’s surprising that they also may be the most under-inspected. Cracks are rare, but they can be repaired if found early. One plant avoided a long forced outage to replace a reheater outlet header by using the correct condition assessments and welding techniques.

-

O&M

SO3’s impacts on plant O&M: Part II

Part I of this three-part series (POWER, October 2006) explored the negative impacts of sulfur trioxide (SO3) on the operation and maintenance of back-end plant equipment. In this issue, we list and quantify the likely and potential benefits of limiting the concentration of SO3 in flue gas to 3 ppm at the entrance to the air heater. Part III—to appear in the April 2007 issue—will describe the characteristics of an optimal SO3 removal technology and present the technical details and operating experience of one patented process that has worked successfully at a half-dozen plants for up to three years.

-

Coal

Sealing abandoned mines with treated flyash kills two birds with one stone

Environmentally benign disposal of coal combustion products/by-products (CCPs) such as flyash and bottom ash has been a problem since the first coal-fired power plant went on-line. In recent years, ways have been developed to recycle CCPs into useful commercial products like bricks and roadbase. This article describes an innovative State of Maryland program that is putting CCPs to yet another use: stabilizing abandoned mines to permanently sequester acids and harmful metals.