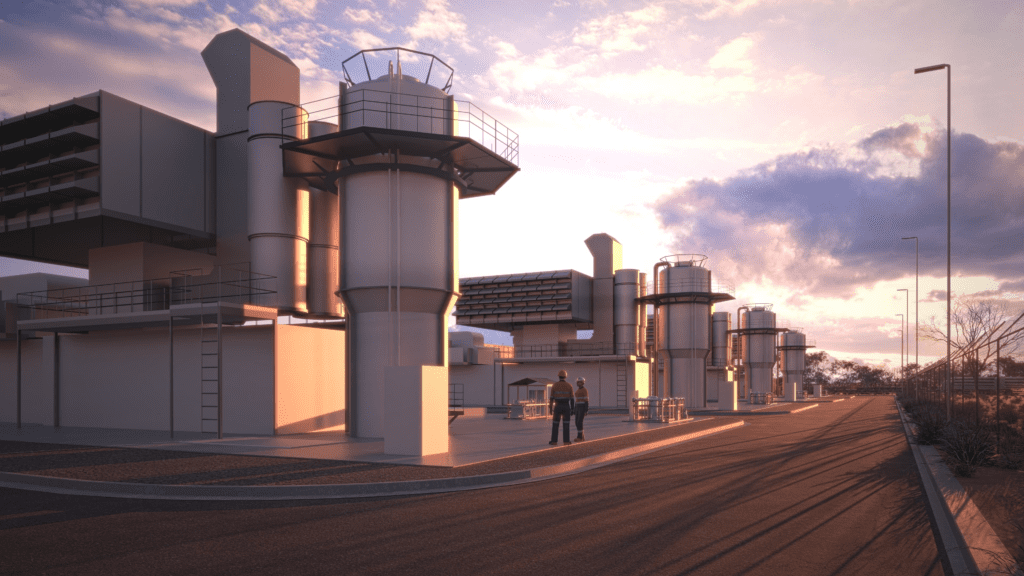

EnergyAustralia has begun operations at the 320-MW Tallawarra B gas-fired power station in New South Wales (NSW)—Australia’s first peaking power plant capable of operating on a natural gas and hydrogen fuel blend. The project’s start on Feb. 19 also marks GE Vernova’s first deployment of a hydrogen-capable dual-fuel 9F gas turbine.

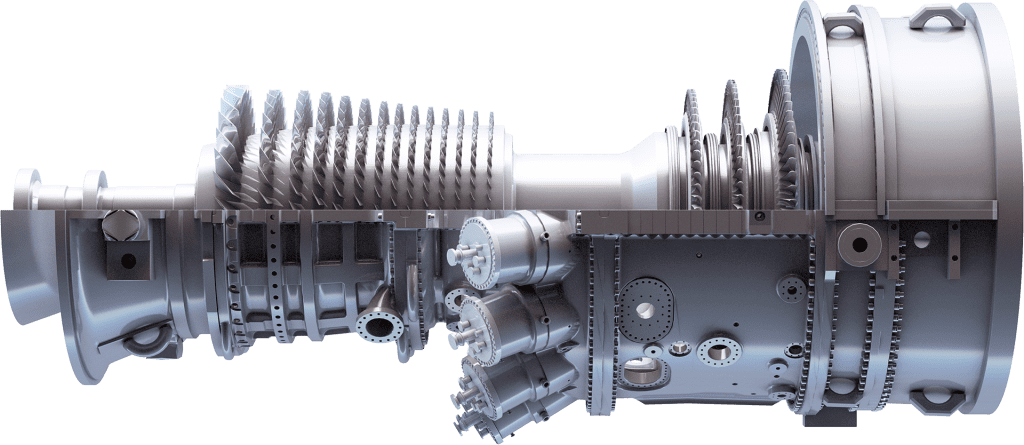

The $300 million ($196 million) open cycle gas turbine (OCGT) project features a GE Vernova 50-Hz 9F.05 gas turbine. It is expected to run initially on natural gas and transition to a blend of 5% of hydrogen by volume by 2025, depending on “the development of a hydrogen manufacturing industry of an appropriate size and scale,” GE Vernova said on Monday.

The project in Yallah (60 miles south of Syndey) is located next to EnergyAustralia’s 440-MW Tallawarra A gas-fired station, a GT26 combined cycle power plant built to replace a 320-MW coal-fired power station that operated until 1989. While Tallawarra A is slated for an efficiency upgrade later this year, Tallawarra B’s fast-start and dual-fuel capabilities complement Tallawarra A’s flexibility attributes, which are growing crucial for regional balancing. Tallawarra B is notably Australia’s “first gas-peaking power station with total emissions offset over its operational life,” said EnergyAustralia.

The company, a CLP Group subsidiary that serves as a major retailer across eastern Australia and holds a 5-GW generation fleet, said NSW’s fast-start and flexibility needs have grown more urgent after AGL, Australia’s largest generator, shuttered its massive 1.6-GW coal-fired Liddell Power Station in the NSW Upper Hunter region in April 2023. “Tallawarra B enables and complements more renewables entering the system as coal-fired power stations retire,” said Mark Collette, EnergyAustralia’s managing director.

Pinning Down Adequate Hydrogen Supply

Development of Tallawarra B kicked off in May 2021, furnished with A$78 million from the NSW government to help deliver financial close, along with A$5 million from the federal government to ensure the project was hydrogen-ready.

Under the May 2021 funding agreement, EnergyAustralia will buy 200,000 kilograms of renewables-based hydrogen—up to 5% of the plant’s fuel use—starting in 2025 to offset direct carbon emissions from the project over its operational life. According to NSW’s Hydrogen Strategy, unveiled in October 2021, the funding will position Tallawarra B as a foundational off-taker of hydrogen produced by the proposed Illawarra hydrogen hub. In March 2023, the NSW government awarded Linde subsidiary BOC A$28.5 million to develop the hydrogen technology hub on its existing Port Kembla operations site.

BOC, however, has not yet made a final investment decision. The proposed hub is expected to include a 10-MW electrolyzer with the potential to produce about 4 tonnes of hydrogen per day, though over the long term, the project could be expanded to a 650-MW electrolyzer. NSW, notably, in August 2023, also furnished Origin Energy with A$45 million to develop the Hunter hydrogen hub 200 miles north in Newcastle.

Tallawarra B: Purpose-Designed

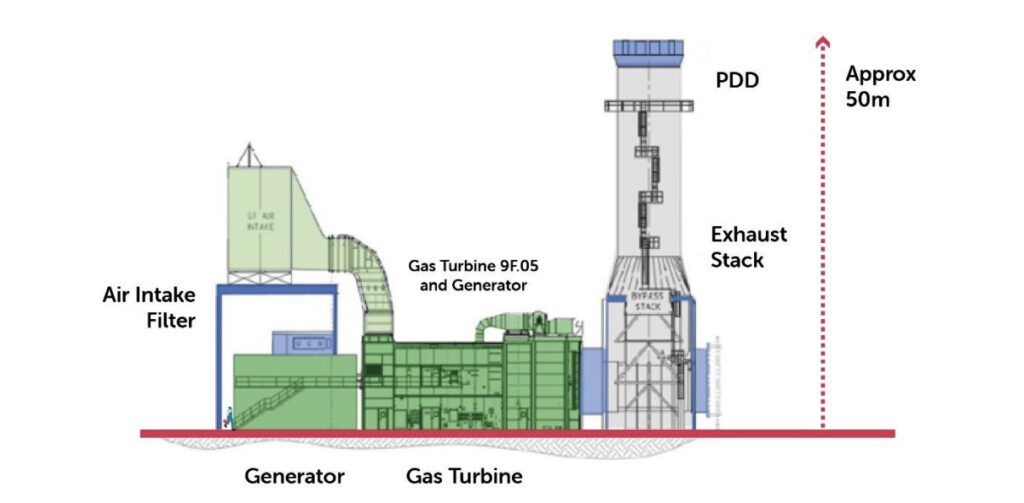

EnergyAustralia said it chose an OCGT for Tallawarra B over a combined cycle gas turbine “because it is faster to start and can provide electricity into the grid more quickly when there is high demand.” It ultimately picked a consortium comprising GE Vernova and engineering, procurement, and construction (EPC) firm Clough to build the project.

GE provided the plant’s GE 9F.05 gas turbine—its most advanced F-class machine—along with the project’s A78 generator, a generator step-up transformer, and a Mark* Vie control system. Gas turbine accessories were “packaged in modules for the project, which reduced on-site installation work while offering simpler and faster serviceability for the plant operator,” it noted.

As a crucial project component, GE Vernova also provided a A$13 million Plume Dispersion Device (PDD), a 54-tonne device that sits on top of the exhaust stack to reduce the plume’s vertical velocity. “An OCGT works in a manner similar to a jet engine,” EnergyAustralia explained. “The exhaust from the turbine is incredibly hot and, as we know, hot air rises. The heat of the exhaust gases relative to the outside air temperature means it rises rapidly in the air. Without a PDD on top of the exhaust stack, the exhaust gases would rise into the atmosphere as a column of hot air.”

The PDD at Tallawarra B, crucially, minimizes the “potential effects on the safety of aircraft using the nearby Shellharbour Airport,” EnergyAustralia said. Tallawarra B’s “exhaust gases must meet a critical plume velocity of no more than 6.1 meters/second or below 700 feet above mean sea level, as stipulated by the Civil Aviation Safety Authority,” it noted.

The World’s First GE Vernova Dual-Fuel 9F.05 Gas Turbine

Since launching its first F-class machine in 1991, GE Vernova has received orders for over 450 GE 9F gas turbines. The launch of Tallawarra B in 2021 marked not only the first of its kind built in Asia but also the inaugural F-class machine designed to run on a blend of natural gas and hydrogen.

As Jeffrey Goldmeer, now GE Vernova director of Hydrogen Value Chain, explained to POWER in 2021, the F-class gas turbine’s hydrogen capability as configured with the DLN2.6+ combustion system “is closer to 15% to 20%.” The pilot project Tallawarra B was planned to begin operations with 5% hydrogen to take into account available green hydrogen, he suggested. “So that’s not a gas turbine limitation, that’s an entry point to the gas turbine,” he said. “There’s room to grow as the green hydrogen supply chain increases, as production increases.”

GE Vernova has since made significant headway in exploring combustion solutions to enable 100% hydrogen combustion throughout its fleet. That includes a series of notable hydrogen combustion “firsts” for its H-class and aero-derivative gas turbines, including at commercial power plants. However, it has also set out to demonstrate hydrogen combustion’s system peaking capabilities. Later this year, for example, a fully functional project at Duke Energy’s DeBary power plant in Florida is slated to demonstrate an integrated 100% hydrogen power-to-power system for commercial peaking, leveraging one of DeBary’s four 83-MW GE 7E gas turbines.

The company’s efforts to outfit its F-class with 100% hydrogen capabilities are, for now, progressing under a project that is backed with $6.6 million in funding from the U.S. Department of Energy. In tandem, the company has separately set out to develop a retrofittable 100% ammonia-capable gas turbine combustion system that would be compatible with GE’s existing 6F.03, 7F, and 9F models. A collaboration announced in January 2024 with Japanese integrated heavy industry group IHI Corp. targets a potential commercially available ammonia-capable product by 2030.

Ramesh Singaram, president and CEO of GE Vernova’s Asia Gas Power segment, on Monday highlighted Tallawarra B’s significance, suggesting that the project would serve as a demonstration of the “substantive role that gas technologies can play in reducing carbon emissions, ensuring reliable electrical supply, and fighting climate change.” GE Vernova is “committed to delivering reliable, stable, cost-effective energy that supports energy providers, like EnergyAustralia, to assist with developing a hydrogen supply chain and transitioning Australia to a lower carbon future,” he said.

Australia’s Quest for Decarbonized Reliability

Tallawarra B marks the first gas-fired power station built in NSW in more than a decade, but it is just one of several capacity additions the state needs to urgently bolster its reliability profile.

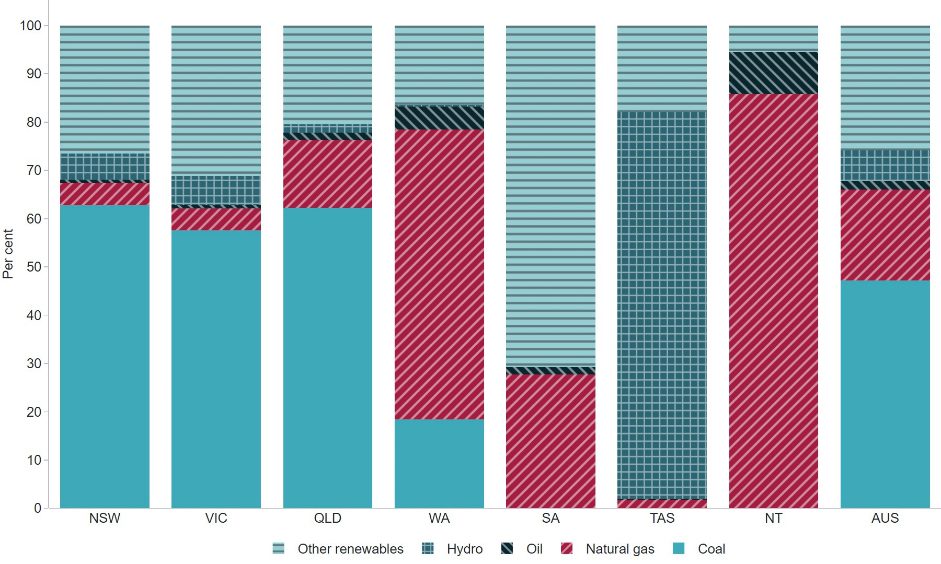

NSW currently procures around 60% of its power from four coal plants, but by 2033, three are set to retire: the 1.3-GW Vales Point B (by 2033), 3-GW Eraring, and 2.7-GW Bayswater (2030–2033). The state’s urgency balance its supply and demand profile amplified further in February 2022, when Origin Energy notified the Australian Energy Market Operator (AEMO) of plans to retire the 3-GW Eraring Power Station early in August 2025, citing economic hurdles.

While the AEMO’s latest Energy Security Target (EST) Monitor Report for NSW forecasts a surplus of up to 1 GW for the region through 2025, it has warned that Eraring’s closure will precipitate a supply shortfall of up to 1.4 GW by 2030. “At this point, firm capacity from outside this sub-region would be called upon to meet demand in peak demand periods, but cannot be made available to the majority of New South Wales customers due to forecast constraints on intra-regional transmission infrastructure,” it said.

At least over the near term, NSW may add 650 MW of additional variable renewable energy (VRE) generation. By 2033, new VRE sources will add up to 3 GW. NSW plans to firm up the VRE with 3.7 GW of additional storage by 2033.

That will include Snowy Hydro 2.0, a 2.2-GW pumped hydro storage megaproject that is projected for completion in December 2028. Another notable major storage project under construction is Black Rock’s Waratah Super Battery, an 850-MW/1,680-MWh lithium-ion battery storage project that should come online in 2024/2025. When operational, that project could become the world’s largest battery energy storage system, Black Rock claims.

However, the AEMO stresses that gas power will continue to play a significant role. Along with Tallawarra B, Snowy Hydro is expected to add a 660-MW OCGT plant near Kurri Kurri by the end of 2024.

The Kurri Kurri project, known commercially as the Hunter Power Project, will feature two Mitsubishi Power hydrogen-ready F-class (M701F) gas turbines. Snowy Hydro expects the OCGTs will be capable of initially running on up to 15% hydrogen. With “additional investment, we expect they will be capable of up to 30% hydrogen,” it said. Like Tallawarra B, “the ability to run on hydrogen is dependent on the balance of plant modifications and the availability of green hydrogen,” the company noted.

Tallawarra A Poised for Future-Resilient Upgrade

On Monday, EnergyAustralia’s Managing Director Collette suggested the company’s hydrogen capability forms a cornerstone of its future strategy. “We are positioning both Tallawarra stations to play a long-term role in New South Wales’ energy future and our own plans to achieve net zero by 2050,” he noted.

At Tallawarra A, EnergyAustralia is pursuing a project to upgrade Tallawarra A’s 14-year-old GT26 gas turbine with a high-efficiency (HE) upgrade. The HE upgrade “blends cutting-edge technology from GE’s industry-leading F and H class fleets with additive manufactured parts and innovations in aerodynamics, material science, and combustion dynamics,” GE Vernova has noted.

While GE Vernova last year suggested the upgrade may be operational by mid-2024, EnergyAustralia has made investments to ensure Tallawarra A is “also gas/hydrogen-capable when the green hydrogen manufacturing industry in the Illawarra is of an appropriate size and scale,” Collette said.

“In April, we will commence a [A$90 million ($59 million)] upgrade and overhaul of Tallawarra A,” he noted. “This will increase the capacity and efficiency of the station from 440 MW to 480 MW while also enabling the use of up to 37% hydrogen as a fuel when green hydrogen is commercially available.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).