In This Issue

-

Business

The return of compressed air energy storage

Faced with soaring energy prices, researchers and developers worldwide are giving compressed air energy storage (CAES)—a technology almost 50 years old—a dusting, a spit shine, and a new life. In particular, they see it as a critical component for the dispatch of wind and other renewable power. The technology, which involves storing off-peak-generated energy in […]

-

News

Double duty flowmeter

As fluid passes through Exact Flow’s new DX-DL dual-rotor turbine flowmeter, the dual rotors become hydraulically coupled due to their counter-rotation. Not only does this allow the rotors to overcome the inertia and drag that typically affect single-rotor turbine flowmeters, it also extends the flow range to 500:1—five times the 100:1 flow range of a […]

-

Coal

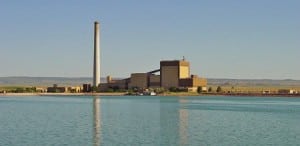

Rawhide Energy Station, Fort Collins, Colorado

Top Plant: The staff of the Rawhide Energy Station have been racking up operating stats and an environmental performance record that is the envy of other plant managers. In the past decade Rawhide has enjoyed an equivalent availability factor in the mid- to high 90s and an average capacity factor approaching 90%. Still not content with this performance, Rawhide invested in new technology and equipment upgrades to further optimize performance, reduce emissions, and keep cost competitive.

-

News

Data interface flaps

Enclosure manufacturer Rittal Corp.’s latest products are designed to be incorporated into electrical systems to help ensure safety against arc flash hazards. Data interface flaps, shown here, provide rapid system access via integrated USB, SUB-D9 RJ 45, and NEMA 5-15 sockets when needed. The affected enclosure remains closed and is thereby protected from ambient influences […]

-

O&M

Entergy’s “big catch”

Entergy christened its Performance Monitoring and Diagnostic Center several years ago to leverage the expertise of its most senior operators and technicians across the company’s entire fleet of plants. The center also makes use of advanced software tools that increase plant availability and reliability by identifying faults before they become major, unplanned outages. The center paid for itself for years to come with a single “big catch” last year.

-

News

Flaw-finding family

GE Sensing & Inspection Technologies’ new family of ultrasonic flaw detectors incorporates conventional and phased array ultrasound technology in three upgradeable models: Phasor CV, Phasor 16/16 Weld, and Phasor XS. Each solution, designed for applications ranging from corrosion monitoring to defect detection and sizing, is compliant with all major inspection codes. The Phasor XS (shown […]

-

Coal

Map of Coal-fired Power Plants in the United States

Courtesy: Platts Data source: Platts Energy Advantage and POWERmap. All rights reserved.

-

News

Tight seal, easy retraction

An advanced seal technology for hydraulic bolt tensioners recently developed by UK-based Boltight Ltd. takes advantage of the latest composite materials to eliminate oil leakage while allowing the tensioning piston to be retracted more easily after use. The new seals are a two-piece self-energizing design with an “O” ring made from a self-lubricating and durable […]

-

Coal

Boryeong Thermal Power Complex, Boryeong-Si, Chungcheongnam-do Province, South Korea

Top Plant: From tall skyscrapers and flashing neon signs to Buddhist temples and pagodas, South Korea is a mixture of the new and old Asia. Doing its part to help modernize this country, the Boryeong Thermal Power Complex operates six coal-fired 500-MW units that provide electricity to power South Korea’s economic growth. One of the important reasons for this facility’s overall success is its operational reliability. An example of this is Boryeong Unit 3’s outstanding achievement of 3,000 days of trouble-free operation.

-

News

Sonar sensors

Hawk Measurement Systems has launched a new line of “fourth generation” sonar transducers designed for improved sensing of interface levels in clarifiers and thickeners. The new transducer designs include three to seven sonar crystals mounted in a single head. Each sonar array produces a concentrated sonar beam, providing more emitted power and collecting more returned […]

-

Coal

Dubuque Generating Station, Dubuque, Iowa

Top Plant: Alliant Energy’s Dubuque Generating Station is a fine example of why small doesn’t mean insignificant in the power generation industry. This winner of the EUCG Best Performer award in the small plant category shows that its operating excellence towers over that of many larger and much newer coal-fired power plants.

-

Commentary

Transmission: Lines that connect the renewable energy dots

The United States is used to transporting fuels to electric generation centers that are close to where the power supply is needed. We see trains carry coal by the carload from resource-rich areas to generation centers across the country. Natural gas is distributed through pipelines. Even uranium is transported to supply our nuclear stations. However, […]

-

Rope-a-dope politics

Republican presidential candidate John McCain made reference to the word “fight” 25 times during his September 4 nomination acceptance speech. While watching McCain’s histrionics, my mind wandered back to another historic fight—the “Rumble in the Jungle.” Muhammad Ali, arguably the best boxer who ever stepped into the squared circle, was pitted against then-World Champion George […]

-

Coal

J.K. Spruce Power Plant, Unit 1, San Antonio, Texas

Top Plant: CPS Energy’s J.K. Spruce Power Plant, Unit 1 was recently recognized by the EUCG Fossil Productivity Committee as the best performer in the large coal plant category over the 2002-2006 evaluation period. The competition was tough, with more than 80 plants in the running, but Unit 1 emerged as the clear winner by earning top points for high plant reliability and very low nonfuel O&M costs.

-

Water

Cooling water intake structure regulations

In the wake of a recent federal case, large power plants are off the hook for now as far as complying with the U.S. Environmental Protection Agency’s (EPA’s) 2004 rule intended to protect fish and other aquatic organisms by controlling cooling water intake practices.

-

News

Hand-arm vibration gauge

No U.S. federal standards exist to limit worker exposure to hand-arm vibration (HAV), but the National Institute for Occupational Safety and Health suggests that high HAV acceleration levels (5-36 m/s2) can cause physical effects—and even permanent injury—if left unchecked and untreated. A new series of triaxial accelerometers launched this August by PCB Piezotronics’ Larson Davis […]

-

Coal

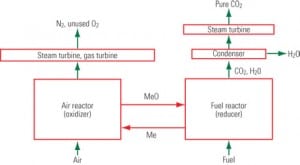

Chemical looping and coal

What does human metabolism have in common with coal combustion? Quite a bit, it turns out, say researchers at the National Energy Technology Laboratory (NETL) who are studying chemical looping combustion (CLC) involving coal gasification, an emerging technology for clean energy production from fossil and renewable fuels.

-

Legal & Regulatory

Texas loses “food vs. fuel” biofuel feud

How often do you get a clash between two great Lone Star icons?

-

Business

World energy use to surge 50% between 2005 and 2030

Worldwide energy consumption is projected to grow 50% between 2005 and 2030, driven by robust economic growth and expanding populations in the world’s developing countries, the U.S. Energy Information Administration (EIA) said in a reference case projection from its International Energy Outlook 2008 in June.

-

Coal

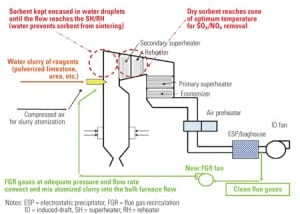

Bringing down the cost of SO2 and NOx removal

A twist on an old technique, flue gas recirculation, helps prevent slagging in the upper furnace and convective pass, according to pilot testing recently completed by APTECH CST and the Southern Research Institute. The technology—along with a companion technology for furnace sorbent and urea injection for SO2 and NOx control—could help owner/operators of smaller, older coal-fired plants meet emissions limits at a reasonable cost.

-

Geothermal

U.S. sees 20% jump in planned geothermal

The U.S., which continues to lead the world in on-line geothermal energy capacity, saw a 20% jump in new power projects since January this year, a survey released by the Geothermal Energy Association (GEA) in August showed.

-

O&M

Managing software life-cycle issues

Software ranges from shrink-wrapped products available “off the shelf” to custom corporate implementations of enterprise systems that require sessions with shrinks to keep everyone sane. Regardless of its complexity, every piece of software a plant uses, or interfaces to, poses critical issues that require life-cycle management. Although functionality has always been the chief specification for software, plants must pay far more attention to long-term quality issues. These two concerns are often at odds with each other.

-

Hydro

New workshop completes first overhaul

In early August, a special transport departed from Voith Siemens Hydro’s Heidenheim workshop bearing the company’s 300-ton, 300-MVA hydro motor-generator back to Schluchseewerk AG’s Wehr pumped-storage station in Germany’s Black Forest.

-

Coal

Finessing fuel fineness

Most of today’s operating coal plants began service at least a generation ago and were designed to burn eastern bituminous coal. A switch to Powder River Basin coal can stress those plants’ boiler systems, especially the pulverizers, beyond their design limits and cause no end of operational and maintenance problems. Many of those problems are caused by failing to maintain good fuel fineness when increasing fuel throughput.

-

Solar

Scorching asphalt and solar power

Through asphalt, researchers are looking to develop a solar collector that could turn roads and parking lots into ubiquitous—and inexpensive—sources of electricity and hot water.

-

O&M

Repairing low-pressure rotors with cracked blade attachments

An increasing number of low-pressure steam turbines—especially at supercritical fossil units—have experienced stress corrosion cracking in the blade attachment region of their low-pressure rotors. Approaches to solving this problem range from redesign of the attachment and blade replacement to in-situ weld repair. Regardless of the procedure selected, the solution must completely restore the turbine performance while minimizing outage duration.

-

Business

POWER digest (October 2008)

News items of interest to power industry professionals. EDF and CGNPG create joint venture for Taishan nukes. Électricité de France (EDF) and the China Guangdong Nuclear Power Group (CGNPG) on Aug. 10 finalized a framework agreement made earlier, in November 2007, and formally created a joint venture company to build and operate two evolutionary pressurized […]

-

Coal

TS Power Plant, Eureka County, Nevada

Top Plant: Not all coal-fired power plants are constructed by investor-owned utilities or independent power producers selling to wholesale markets. When Newmont Mining Corp. recognized that local power supplies were inadequate and too expensive to meet long-term electricity needs for its major gold- and copper-mining operations in northern Nevada, it built its own generation. What’s more, Newmont’s privately owned 200-MW net coal-fired plant features power plant technologies that will surely become industry standards. Newmont’s investment in power and technology is also golden: The capital cost will be paid back in about eight years.

-

Coal

Computer simulation as a NOx reduction design tool

A utility evaluated various methods of obtaining a NOx reduction of at least 30%, as required by upcoming regulations for its boiler, which originally produced 0.54 lb of NOx/million Btu at 410 MW full load. Nalco Mobotec engineers performed a computational fluid dynamics (CFD) simulation of the boiler to first understand the boiler’s combustion process and then determine the most economical method to achieve the required NOx reduction.