Coal Combustion Residuals Rule Compliance Strategies

The Environmental Protection Agency’s rule to regulate the disposal of coal combustion residuals as solid waste went into effect last fall. After evaluating the available solutions and technologies, here’s what some experts consider the safest and most effective approaches for complying with the rule and protecting the environment.

A little over a year ago, the Environmental Protection Agency (EPA) published a final rule to regulate the disposal of coal combustion residuals (CCR) as solid waste under subtitle D of the Resource Conservation and Recovery Act (RCRA). The rule, which establishes technical requirements for CCR landfills and surface impoundments, went into effect on October 19, 2015. Even before the final rule was signed, power generators spent a great deal of time trying to understand their options and make decisions about how best to comply with the rule’s requirements.

But how do companies know if they have the right plans in place? POWER interviewed a couple of experts and reviewed the actions taken by several large utilities to see if any environmental best practices have emerged. The insights we gathered might help you determine if your facility is taking the most effective actions to prevent unnecessary and costly CCR releases from occurring. They could also keep you out of the courtroom.

What Are the Requirements?

The EPA’s final rule establishes minimum national criteria for CCR landfills, CCR surface impoundments, and all lateral expansions of CCR units. The requirements include location restrictions, liner design criteria, structural integrity requirements, operating criteria, groundwater monitoring and corrective action requirements, closure and postclosure care requirements, and recordkeeping, notification, and Internet posting requirements. Some of the requisite steps are aimed at reducing the risk of catastrophic structural failures, while others are focused on protecting groundwater.

Concerning the structural integrity design criteria, the rule requires owners and operators to periodically conduct a number of assessments, such as periodic structural stability assessments by a qualified professional engineer and periodic safety factor assessments designed to determine if minimum engineering factors of safety are achieved. A periodic hazard potential classification assessment must also be conducted to evaluate the damage that could occur if there were a failure of a CCR surface impoundment.

Weekly inspections of CCR units must be completed, and monthly monitoring of instrumentation is required. In addition, some surface impoundments must have emergency action plans developed to detail actions to be taken to protect communities in the event that there is an issue with the structural safety of the unit.

To protect groundwater, the EPA established provisions requiring owners and operators to install a system of monitoring wells and specified procedures for sampling the wells and analyzing the data to detect the presence of hazardous constituents. If hazardous constituents exceed groundwater protection standards, immediate corrective actions must be implemented to clean up the contamination caused by the unit. If the unit is an unlined surface impoundment, owners and operators must begin the closure process.

Five location restrictions are established by the rule to ensure appropriate siting of landfills and surface impoundments. Specifically, the location criteria include restrictions relating to placement of CCR above the uppermost aquifer, in wetlands, in fault areas, in seismic impact zones, and in unstable areas.

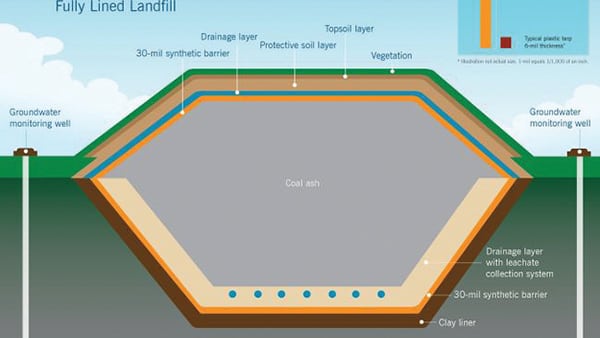

All new landfills, new surface impoundments, and lateral expansions must have a composite liner, which is a liner system consisting of two components—a geomembrane and a two-foot layer of compacted soil—installed in direct and uniform contact with one another. In addition, new landfills are required to operate with a leachate collection and removal system designed to remove excess leachate that may accumulate on top of the composite liner.

Although existing CCR landfills are not required to close or retrofit with a composite liner and a leachate collection and removal system, they must meet all applicable groundwater monitoring and corrective action criteria to promptly address any groundwater releases.

The requirements mentioned here are not all-inclusive. The rule should be studied in its entirety to fully understand all of its provisions, including additional operating criteria, closure and postclosure requirements, and recordkeeping, notification, and Internet posting requirements, which have not been detailed in this article.

One Solution Does Not Fit All

Although it would be nice to take a cookie-cutter approach and simply do what others have been doing successfully, it is unlikely that you can merely copy your neighbor. Kent Nilsson, PE, a consulting engineer for TRC Companies Inc.—a national engineering, consulting, and construction management firm—told POWER that every facility is different. But that doesn’t mean you can’t learn from and utilize the best practices developed by others.

Nilsson offered three “Habits of Highly Effective CCR Managers.” He said effective managers do the following:

■ They understand that CCR materials have some unique physical properties that can have significant effects on constructability and on project schedules. For example, the properties can include low hydraulic conductivity and low strength in an unconsolidated condition, which must be factored into plans.

■ They secure critical resources well in advance of the proposed construction activity. For example, some utilities are having difficulty procuring construction materials—such as geosynthetic liners, crushed stone, and topsoil—and finding qualified drilling contractors for the installation of well-monitoring systems. Locking up scarce items before they are needed can prevent headaches and avoid project delays.

■ They recognize the tremendous value offered by pilot studies or field trials of proposed construction methods. For example, evaluating material management and dewatering options (such as testing traditional dewatering and mechanical excavation versus hydraulic dredging), placement of bridge fills over soft CCR materials, handling of effluent discharge waters, and construction of treatment wetlands can all provide valuable information in advance of full implementation.

Site-specific considerations, such as geographic setting, geologic conditions, CCR characteristics, site layout, plant operations, and community involvement, can all come into play when deciding on a game plan. While the “most effective” method will be unique to each site, the ideal solution will usually result in the following conditions being met:

■ It is fully compliant with the CCR rule.

■ It is protective of human health and the environment.

■ It is cost effective.

■ It allows beneficial use.

■ It requires minimal disruption to existing operations.

Beneficial Use and Onsite Disposal

The final rule provides a definition of beneficial use to distinguish between beneficial use and disposal. The definition essentially states that the CCR must provide a functional benefit; must substitute for the use of a virgin material; and must meet relevant product specifications, regulatory standards, or design standards. There are additional requirements for unencapsulated use of CCR, but we won’t get into those here.

The reason that understanding beneficial use is so important is that the rule does not regulate CCR that are beneficially used. However, Nilsson said beneficial reuse of CCR materials removed from surface impoundments appears to be limited to a smaller percentage of facilities now.

Haul distances, end-user markets, processing facility capacities, and public sentiment most often govern the feasibility of reuse. Even though CCR material makes a competent structural fill and has been used in mass earthwork projects, such as airport runway expansions and mine reclamations, the public seems to be increasingly wary of such uses, even when protective liners and leachate collection systems are put into place.

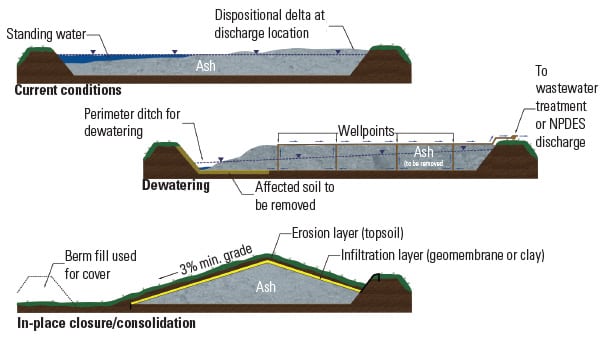

Absent any mining of CCR materials from existing disposal units for beneficial reuse, Nilsson said generators’ preferred solution seems to be storage/disposal of CCR materials on plant properties. For in-place closures, some CCR material can be removed from existing impoundments and used as a structural fill for a portion of the unit’s closure or to close adjacent impoundments (Figure 1).

Storing or disposing of material onsite reduces the volume of haul trucks on public highways, which is an advantage because it eliminates the potential for truck accidents or spills after a truck leaves the site. It also avoids owners’ exposure to risk of comingling CCR with waste from other entities, which can happen at a commercial solid waste disposal facility.

Nilsson said some owners of existing CCR impoundments don’t fully appreciate drainage limitations of the materials. As a result, they don’t allow sufficient time or commit sufficient resources to the implementation of dewatering practices.

Ash commonly has a hydraulic conductivity ranging between 10–4 cm/sec and 10–5 cm/sec (0.03 ft/day to 0.3 ft/day). Dewatering ash by gravity flow can only be accelerated by increasing the hydraulic gradient or by shortening the length of the drainage path. Ash that is not drained will typically be weak and unstable.

One unique property of unconsolidated CCR is its susceptibility to liquefaction when subjected to vibration. Under these conditions, the CCR can turn instantly from a solid into a liquid, making it impossible to grade or support the load of construction equipment (Figure 2). A project can immediately fall behind schedule if sufficient time and dewatering infrastructure aren’t included in the plan.

|

|

2. Liquefaction. Unconsolidated coal combustion residuals can turn quickly from solids into liquids. Courtesy: TRC Companies Inc. |

While future disposal in a lined onsite landfill can be a cost-effective solution (see sidebar), permitting a new facility can be problematic if a plant is in close proximity to large bodies of surface water or has insufficient depth to groundwater.

An Environmental Lawyer’s Perspective

According to Frank Holleman, senior attorney for the Southern Environmental Law Center (SELC)—a nonprofit that uses the law to, in its words, “stop environmental abuses”—the EPA’s rule “is not the final word, but an essential floor of protection.” Holleman told POWER that a utility can potentially comply with the CCR rule, while still violating the federal Clean Water Act, the federal RCRA statute, state antipollution laws, and other legal protections.

“The only way for a utility to protect itself, its executives, board members, employees, and shareholders from civil and criminal liability, financial risk, and serious reputational harm is to move its coal ash from wet unlined waterfront storage to dry, lined storage away from waterways and separated from groundwater,” Holleman said.

Holleman pointed to a couple of South Carolina companies that he said are doing things right. First he noted that Santee Cooper is removing all coal ash from its unlined waterfront coal ash storage sites (Figure 4). He said the company has permitted and constructed a Class 3 (lined) industrial landfill at its Cross facility and is permitting another Class 3 landfill at its Winyah Generating Station. Santee Cooper has partnered with The SEFA Group Inc. for the construction of a $40 million plant in Georgetown County to reprocess ponded ash into concrete, and it has contracts with others for concrete recycling.

|

|

4. Ash excavation. Removing coal ash from unlined storage sites and disposing of it in fully lined landfills is costly, but less risky in the long term, for generators. Courtesy: TRC Companies Inc. |

South Carolina Electric and Gas Co. is taking similar steps. It has a lined Class 3 industrial landfill at its Wateree Station near Columbia and is removing all the ash from an unlined pit near the Wateree River. Since it began removal about four years ago, arsenic groundwater contamination has declined by about 90%. According to Holleman, the removal is also eliminating a threat to the Congaree National Park, which is three miles downstream from the site.

At the other end of the spectrum, Holleman suggested that the Tennessee Valley Authority (TVA) has not learned from the 2008 coal ash spill at its Kingston facility—arguably the worst coal ash disaster in U.S. history. SELC filed litigation on behalf of conservation groups in 2015 alleging that the TVA is violating antipollution laws in the way it stores coal ash at its Gallatin facility near Nashville. The TVA recently responded with a proposal, but Holleman said the plan leaves the ash where it is, which SELC claims includes areas of karst geology inundated with sinkholes.

Scott Brooks, TVA public relations specialist, told POWER that the TVA has committed to spending $1 billion to $2 billion to convert all of its CCR storage from wet to dry systems. It has also spent another $1 billion to restore the area around the Kingston spill to conditions that it claims are “as good or better than before the spill.”

“We appreciate that SELC has its own agenda that it is seeking to advance here, but TVA has a public mission that guides its activities. Its responsibilities have been set by Congress and are much broader than the limited focus that SELC applies to itself,” Brooks said.

The TVA is in the process of preparing an Environmental Impact Statement to help it decide how to close coal ash impoundments and how to comply with the EPA’s CCR rule. It has yet to decide what methods to use.

“In its CCR Rule, EPA encouraged utilities to close impoundments quickly because it found that dewatering ponds significantly reduced the risk of structural failures as well as groundwater contamination. That is exactly what TVA is proposing to do at 10 of its impoundments,” Brooks said.

Constructed Wetlands

Much of the focus in CCR management has centered on the handling of the solids. However, Nilsson said long-term management must also include handling and treating leachate from disposal cells and discharges from low-volume waste ponds.

“The quality of the effluent is expected to be increasingly scrutinized even while current discharge limits are being met,” Nilsson said.

The EPA’s Effluent Limitations Guidelines, which became effective on January 4, 2016, tighten current discharge limits and force more rigorous treatment for some waste streams. Long-term treatment can be energy-intensive and costly over the life of a facility. Nilsson suggested that passive treatment, using a constructed wetlands system (Figures 5 and 6), could provide a highly effective alternative in certain situations.

|

|

5. A natural filter. Constructed wetlands are treatment systems that use natural processes involving wetland vegetation, soils, and their associated microbial assemblages to improve water quality. Courtesy: Matt Huddleston |

|

|

6. Multiple cells form the whole. Wetlands can be designed in a variety of system types and configurations to meet specific wastewater needs. Every site is unique, and the design of a constructed wetland system is generally site-specific. Courtesy: Matt Huddleston |

Although a constructed wetlands treatment system is a relatively new technology, its effectiveness in treating CCR contact water has been demonstrated for at least 15 years. It offers the following benefits:

■ With effluent-specific design of substrate, retention time, and vegetation, constructed wetlands have been effective in removing metals and constituents common to CCR materials.

■ Constructed wetlands do not require periodic harvesting and disposal of the vegetation because of the oxidation/reduction reactions at the root zone. The vegetation continues to accrue over the life of the system, providing a secondary benefit of carbon sequestration.

■ With the appropriate topography and hydraulic gradient, constructed wetlands can be designed as passive treatment systems. Frequently, such systems can be constructed within the footprint of a former impoundment that has been “clean-closed” and vacated.

■ In some cases, constructed wetlands can serve to provide credits for wetlands banking.

Even More Restrictions Ahead?

It is worth noting that on April 18, 2016, the EPA asked the U.S. Court of Appeals for the D.C. Circuit to remand certain provisions of the final CCR rule to the EPA for further proceedings. A couple of the more prominent changes that could result include adding boron to the list of constituents that trigger assessment monitoring and corrective action, and removal of an exemption from certain post-closure requirements for inactive surface impoundments closed before April 17, 2018. Visit www.powermag.com for updates on court decisions and news of changes to the final rule. ■

—Aaron Larson is a POWER associate editor.