O&M

-

O&M

Latest Electromagnetic Technology Device Improves Inspection Accuracy and Repeatability

Eddy currents are electrical currents induced within conductors by changing magnetic fields. They are commonly used in nondestructive evaluation (NDE) and corrosion monitoring of structures with painted surfaces. The work of eddy current technicians, who specialize in the electromagnetic modality, requires a high degree of accuracy even when working under challenging testing conditions. Traditionally, technicians relied on […]

-

O&M

Conveyor Inspections: Could a Contractor Help You?

Conducting conveyor inspections and maintenance can pose significant risks to employees, as these activities bring workers into close proximity with the conveyor system under potentially dangerous conditions. Staff members are exposed to moving belts, rolling components, and pinch points, all in an environment that is commonly dirty, distracting, and sometimes noisy. As plants struggle with […]

-

O&M

New Enclosure Solution Enables Remote Monitoring of Battery Backup Systems

With 4.4 million customers and nearly 46 GW of generating capacity, Atlanta-based Southern Co. has doubled the size of its supervisory control and data acquisition (SCADA) system in the past three years and

-

O&M

Robust Bearings Tested for Brazil’s Belo Monte Hydro Project

Brazil’s Belo Monte hydropower project includes a complex of dams, numerous dikes, and a series of canals supplying two different power stations with water. With a rated capacity of 11,233 MW, it will be the

-

O&M

Site-Specific Factors Are Critical for Compliance with Final 316(b) Existing Facilities Rule

On May 16, 2014, the Environmental Protection Agency (EPA) is scheduled to release its long-delayed final 316(b) rule for existing facilities. The rule—which was supposed to have been issued Apr. 17 after

-

O&M

Managing the Changing Profile of a Combined Cycle Plant

With the growing need for operational flexibility across the power industry, the combined-cycle gas turbine (CCGT) fleet is increasingly being subjected to load-following and cyclic operation. This change in

-

O&M

Fuel Flexibility Is the Gift That Keeps Giving

All power plants must continually strive to control operating expenses, but it is particularly important for coal-fired facilities to cut costs these days to stay competitive while meeting ever-more-stringent

-

O&M

MISO Prepares for Hurricane Season

Todd Hillman As hurricane season begins this year, utilities across the Gulf Coast will have a new partner as they work to keep the lights on after extreme weather events. Starting in late 2013, the

-

O&M

Coal Silo Fires and Hot Spots: Extinguishing and Preventing Recurrence

Many coal-fired power plants in operation today do not have a fire-extinguishing medium installed in their coal storage silos. CO2 injection would generally be the preferred method, and is used in many plants, but what do you do when your plant was left without this option after construction? Wet or just plain “hot” coal making […]

-

O&M

Manpower Report: Power Industry Faces Talent Shortage

A report released on May 5 by staffing firm Manpower suggests that utilities are under a “double squeeze”—a shortage of skilled workers at both the entry and senior level—caused by an aging workforce, advances in technology, and a breakdown in the educational system. In its report, “Strategies to Fuel the Energy Workforce,” Manpower noted that […]

-

O&M

Critical Path: Getting Your Outage Ducks in a Row

It’s no secret that equipment requires maintenance. Just as your personal vehicle needs an oil change periodically, a power plant needs to shut down regularly for a tune-up to take care of all those little

-

O&M

OSHA Revises Standards for Line Work and Electrical Protective Equipment

The Occupational Safety and Health Administration (OSHA) on Tuesday issued a final rule that revises a 42-year-old construction standard for electric power line work to make it more consistent with general industry standards. The final rule, which is scheduled to be published in the Federal Register on April 11 and becomes effective 90 days after that, […]

-

O&M

Safety Is Not an Accident

Many generation companies have made safety a cultural norm, often beginning internal meetings with a safety note and requiring monthly safety training sessions. Zero lost time accidents during the two- or

-

O&M

3D Visualization Could Benefit Plant Inspection Programs

Taking a cue from the petrochemical sector, power plants may be on the cusp of applying high-fidelity 3D models of the as-built plant environment to streamline flow-accelerated corrosion (FAC) and other

-

O&M

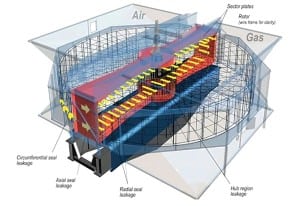

Adaptive Brush Seals Restore Air Preheater Performance

The gas sealing systems used on rotary, regenerative air preheaters (APHs) have evolved little from the metal strip configuration used on the first Ljungström preheaters nearly a century ago. Metallic strip

-

O&M

Modern Polymeric Materials Offer Options for Equipment Repair

Currently accounting for over 16% of global energy production, and with an expected growth rate of 3% per year for the next quarter century, hydroelectric power generation continues to grow as the front runner

-

O&M

Practical Considerations for Converting Industrial Coal Boilers to Natural Gas

Increasing Environmental Protection Agency (EPA) restrictions pertaining to emissions from coal-fired power plants, the increasing cost of coal operations, and the decreasing cost of natural gas provide strong

-

O&M

Customized Storage Solution Improves Efficiency

Omaha Public Power District (OPPD) operates four baseload plants in the state of Nebraska. In 1993, when the North Omaha Station added a new warehouse, OPPD sought help from Vidmar to create effective storage

-

O&M

3D Metal Printing Turbine Replacement Parts Could Cut Repair Times by 90%

3D metal printing is still an experimental process in nearly all industries, used primarily for prototypes and test products. But if Siemens and GE have their way, it will soon become a standard means of rapidly producing small numbers of industrial parts. Siemens announced in December that it would begin using 3D printing—also known as […]

-

O&M

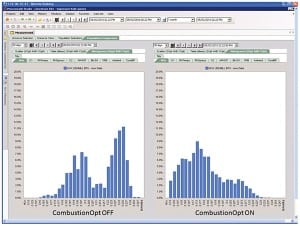

Using Neural Network Combustion Optimization for MATS Compliance

The Mercury and Air Toxics Standards (MATS), promulgated by the Environmental Protection Agency (EPA) on Dec. 21, 2011, set maximum achievable control technology (MACT) emission standards for specific classes

-

O&M

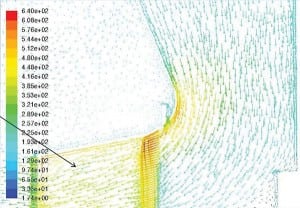

Retrofitting Mechanical Draft Fans to Optimize System Performance

Mechanical draft fans are used exclusively in power generation to move air and gas from one point to another. They create draft in a process system so that fluid media can be induced, forced, and boosted

-

O&M

Upgraded Control Room Consoles Improve Ergonomics

Great River Energy (GRE) is a not-for-profit electric cooperative that generates and transmits power for 28 member cooperatives throughout southern, central, and northern Minnesota and northwestern Wisconsin

-

O&M

Reliable Fire Protection for Turbine Rooms

Fire protection for power plant turbine rooms has typically been a game of tradeoffs. Enclosure integrity issues in older facilities can render CO2 and halon systems ineffective. In new and old facilities

-

O&M

Corrosion Protection for FGD Vessels

Roughly five years ago, the power industry readily embraced the new Alloy 2205 metal as a more lightweight and cost-effective substrate for the construction of flue gas desulfurization (FGD) absorbers and

-

O&M

How Stealth Combustion Losses Lower Plant Efficiency. Part 2: The Solutions

Important process variables that affect unit efficiency were reviewed in Part 1 of this two-part report. Many of those process parameters were also identified as related to boiler air in-leakage. These stealthy combustion losses are difficult to identify or locate yet have a significant effect on boiler combustion efficiency. Keeping your plant operating at or near […]

-

O&M

Day & Zimmermann Focuses on Flexibility

Now more than ever, we see the U.S. power market sharply focused on maximizing return on investment. We see power producers responding to economic uncertainty, high costs for new emission controls, and a

-

O&M

Upgrading a Wired Public Address System with a Wireless Option

The management at a 1,094-MW coal-fired power plant in the Midwest sought to augment their hardwired public-address (PA) system. With hundreds of employees working in varied conditions, a means of

-

Commentary

How U.S. Power Generators Are Preparing for 2014

The business environment for generating companies worldwide continues to become increasingly complex, and not just as a result of regulations. Even in the U.S., the concerns and constraints faced by generators

-

O&M

Preventing Failure of Elastomeric Expansion Joints in FGD Systems

Fossil-fuel-based power generation plants with wet scrubbing systems use slurries of sorbents to remove sulfur dioxide from their emissions. These highly abrasive slurries accelerate wear on the expansion

-

O&M

Reducing Bottom Ash Dewatering System Maintenance

Many coal-fired power plants use water to cool and sluice bottom ash away from the bottom of the boiler for final disposal, and then they recirculate the water for reuse. This system is also known as a

![COAL POWER Stealth Losses Part 2 Fig 1[2]](https://www.powermag.com/wp-content/uploads/2014/01/COAL-POWER-Stealth-Losses-Part-2-Fig-12-286x300.jpg)