New Enclosure Solution Enables Remote Monitoring of Battery Backup Systems

With 4.4 million customers and nearly 46 GW of generating capacity, Atlanta-based Southern Co. has doubled the size of its supervisory control and data acquisition (SCADA) system in the past three years and now has approximately 4,000 devices. Critical power backup systems must be ready if commercial power fails.

Bob Cheney, team leader for the Power Delivery Test Lab at Southern Co., contacted Chad Briddell, product manager at Ventev, the manufacturing division of TESSCO Technologies, because he needed an off-the-shelf enclosure that would house essential SCADA communications devices. Cheney needed the enclosures to be fully integrated by the factory with all the components pre-configured. He was also hoping Ventev would design and include a very important new component.

“I had not been able to find anything already on the market that would test the backup battery and send reports back to me,” explained Cheney. “When the AC power is down, the system rests on the backup battery to keep things going. The whole system can go down because a little $30 battery dies. I needed something that would be able to tell me the battery is good or the battery is bad. You have to understand, Alabama is home to several automobile manufacturers. When the power goes down, they’re not working, and we hear about it.”

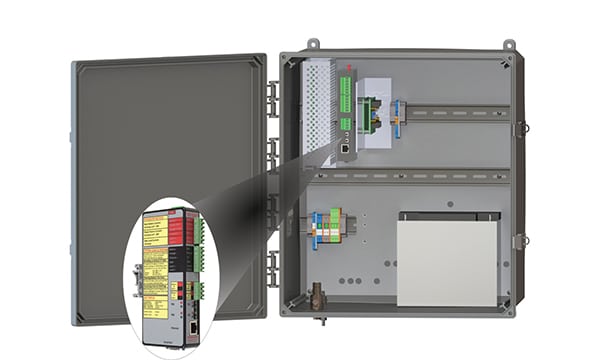

The Ventev team met with Cheney to develop a customer-specific solution. They started with Ventev’s radio-specific outdoor wireless enclosure containing ample power for two radios, radio interface, and environmental protection. The design easily accommodates components such as networking equipment, power conversion equipment, cable grounding, and lightning protection, all of which can be installed in the Ventev factory prior to deployment. The collaboration resulted in a radio-specific outdoor wireless enclosure for Southern’s SCADA devices (Figure 2).

After that, the team worked to address the most important item on Cheney’s wish list. Ventev engineers designed and manufactured a new product—the innovative battery test remote monitor (BTRM)—to perform automatic battery load tests and send alerts via simple network management protocol, text, or email using Ethernet or DNP3 communication protocols. The first-to-market technology allows remote monitoring of battery health for backup supplies relied upon to relay critical data.

“The BTRM sits on the thin rail between the power supply and the battery charger,” Briddell said. “On a user-defined schedule, it takes the AC power offline, forces the load of the system to be supported by the batteries, and then it monitors the voltage of the batteries as it degrades over time. If that rate differs from the factory settings or the factory’s normal conditions, then it raises a red flag.”

Batteries have an operational lifespan that can be reduced by environmental factors. Extreme temperatures are the worst enemy of batteries. The BTRM system offers a simple solution because it is a pass or fail test. It doesn’t provide a lot of data that needs to be analyzed or reviewed. The test will simply identify when a battery is in trouble and needs to be replaced.

“Ventev did what no one else had been able to do,” said Cheney. “They created an enclosure that can let me know the health of the backup battery.” ■

—Edited by Aaron Larson, a POWER associate editor (@AaronL_Power, @POWERmagazine)