Ivanpah Solar Electric Generating System Earns POWER's Highest Honor

The era of Big Solar has arrived, and at the moment there are none bigger than Ivanpah. For overcoming numerous obstacles to build the world’s largest solar thermal plant, the Ivanpah Solar Electric Generating System is awarded POWER’s 2014 Plant of the Year Award.

When the 392-MW Ivanpah Solar Electric Generating System in Nipton, Calif., reached commercial operation in December 2013, with many first-of-a-kind construction elements, it represented a number of significant milestones: The largest solar thermal plant in the world, the first large-scale concentrating solar power (CSP) project in the U.S. to employ power tower technology, and the biggest project funded to date by the Department of Energy’s (DOE’s) Loan Projects Office (LPO).

Now, Ivanpah records another milestone: The first renewable plant to receive POWER’s Plant of the Year Award.

When the facility reached commercial operation, it marked the successful conclusion to a seven-year project that brought together an unusual coalition of industry veterans and newcomers and which—notably for a plant designed from the beginning to limit its impact on the desert ecosystem—faced some unexpected environmental opposition.

Comprising three self-contained units with a total capacity of 392 MW (377 MW net), Ivanpah is a joint effort between BrightSource Energy, NRG Energy (through its subsidiary NRG Renew, formerly NRG Solar), Google, and Bechtel. BrightSource began development in 2006, hoping to leverage its experience in developing CSP technology worldwide. NRG and Google contributed substantial funding, while Bechtel supplied engineering, procurement, and construction (EPC) for the plant. NRG Renew is now the majority owner and in charge of operations for the joint venture.

Few power plants can be called “small,” but nearly everything about Ivanpah is mammoth. The three-unit site sprawls over 3,500 acres—nearly 5 miles from end to end—near Nipton, Calif., about 40 miles southwest of Las Vegas (Figure 1). The facility is large enough to be visible from orbit, and the glow of the three power towers is visible from many miles away when the units are online.

|

| 1. Simply enormous. The Ivanpah site near Las Vegas covers 3,500 acres of the Mojave Desert. Each heliostat field is more than a mile across. Courtesy: NRG |

The station uses 173,500 heliostats (each with two mirrors) to concentrate sunlight on the 459-foot towers. The towers were built this high to increase efficiency and reduce the already large footprint of the site; still, the furthest heliostats out are more than half a mile away from their tower. Four types of heliostats were used depending on the distance. All of them were precisely placed using GPS to ensure accurate alignment, and they are capable of withstanding 85-mph winds.

Each tower holds a 2,100-ton Riley Power boiler that directs steam into a Siemens turbine generator at ground level. The boilers retain enough heat from the previous day to start up on sunlight alone, though an auxiliary boiler is used during cold start conditions or when it is desirable to start up the plant earlier in the morning. A 110-ton tuned mass damper is located at the top of each tower to keep it stable in high-wind conditions.

The facility relies on air-cooled condensers supplied by SPX Cooling Technologies to condense the turbine exhaust. This design was selected in order to help Ivanpah use about 95% less water than a wet-cooled thermal plant. In practice, the plant has been even more water-thrifty than expected: Through the first hundred days of operation, it used only 6% of its allotted 100 acre-feet of water, just under 20,000 gallons per day. The plant’s only water needs are boiler makeup and mirror cleaning. Water is sourced from two wells on the site and purified for use.

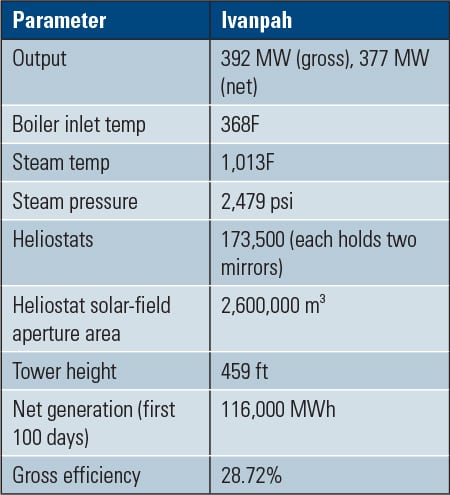

Ivanpah’s operating parameters are given in Table 1.

Development of the Ivanpah Solar Electric Generating System

Oakland, Calif.–based BrightSource began development of Ivanpah in 2006. At the time, the CSP sector—especially solar towers—was still nascent, with only a few relatively small demonstration projects in operation. But BrightSource already had substantial experience developing solar thermal technology, including the 6-MWt Solar Energy Development Center in Israel’s Negev Desert, which came online in 2008. Ivanpah would follow a similar design—but on a much larger scale. Originally planned for 400 MW, the proposed site at Ivanpah dwarfed those earlier systems.

After selecting the site, BrightSource filed for prequalification for the DOE’s Loan Guarantee Program in December 2006 and submitted its application for certification with the California Energy Commission (CEC) in August 2007.

The design for Ivanpah underwent a number of changes during development. As originally proposed, it would have involved 10 smaller power towers, three each for two 100-MW units and four for a single 200-MW unit. Construction was set to begin in 2009, with completion slated for 2012. As is often the case with power plant development, especially large, groundbreaking projects like Ivanpah, those dates would slip.

In October 2007, BrightSource was invited by the DOE to submit a formal application for a loan guarantee, which was completed the following November. The application proceeded swiftly by DOE standards, and the LPO would give conditional approval for $1.37 billion in loan guarantees (an amount later increased to $1.6 billion) in February 2010.

The site for Ivanpah, on Bureau of Land Management (BLM) land near Interstate 15, was carefully chosen to leverage a number of advantages. Foremost among these was supplying renewable energy to California’s investor-owned utilities, which are required to obtain 33% of their electricity from renewable sources by 2020. Power purchase agreements (PPAs) for Ivanpah’s production were signed with Pacific Gas & Electric (PG&E, for 118 MW to 126 MW from Unit 1 and 126 MW to 133 MW from Unit 3) and Southern California Edison (SCE, for 126 MW to 133 MW from Unit 2) in 2009.

The Mojave Desert location enjoys some of the highest insolation in the United States (around 2,700 kWh/m2/yr), making it ideal for CSP. It is also close to the 500-kV Eldorado-Lugo transmission line, which supplies electricity to Southern California. This meant that relatively little transmission infrastructure was needed despite Ivanpah’s remote location. Only one new substation and upgrades to an existing substation and a 115-kV line (upgraded to 220 kV) were ultimately needed. Finally, natural gas for backup and startup generation could be supplied from a pipeline just half a mile to the north.

Construction

In September 2009, BrightSource selected Bechtel as the EPC contractor for Ivanpah. In December, Bechtel signed a project labor agreement with the State Building and Construction Trades Council of California and the Building & Construction Trades Council of San Bernardino and Riverside counties to ensure that California’s local union workforce would benefit from the project. Ultimately, on-site construction staff would peak at about 2,650, the majority of whom were local.

Meanwhile, the California Public Utilities Commission (CPUC) approved the PPA with PG&E in August 2009 and the contract with SCE the following August.

The enormous size of the site and its impact on the desert environment proved to be the first roadblock. Among the concerns was a need to relocate desert tortoises, which are native to the area and federally listed as threatened under the Endangered Species Act, and avoid damage to several protected plant species. In February 2010, BrightSource agreed with the CEC and the BLM to revise the initial design to reduce the overall footprint. This was done largely by reducing the number of power towers from 10 to three. The new towers would also be substantially taller: 459 feet vs. 371 feet (Unit 3) and 262 feet (Units 1 and 2) in the initial design.

This more focused layout would reduce the overall footprint by about 12% and reduce the footprint of the larger Unit 3—where the greatest environmental concerns lay—by about 23%. The new design would have a slightly smaller output but would need 40,000 fewer heliostats (Figure 2).

The new approach passed muster with the CEC, which issued an operating license in September 2010, and the BLM, which approved the project in October. BrightSource and Bechtel broke ground shortly thereafter.

With licenses now in hand, NRG Energy stepped forward to join the project, committing up to $300 million in funding. NRG Renew had been on a shopping spree in California and Arizona, having agreed that June to acquire nine solar development projects from US Solar, an affiliate of Arclight Capital Partners. Ivanpah would be its largest solar project to date.

One last partner would come aboard, but it came from a sector not normally known for investments in power generation. Yet for several years prior, Google had been investing more than $300 million in various renewable energy initiatives, including $10 million in BrightSource. None of its prior solar investments were the size of Ivanpah, however. In April 2011, Google was ready to make a more significant move, committing $168 million to the project.

Google’s investment was part of its goal to spur development of renewable energy. At the time, Rick Needham, Google’s director of energy and sustainability said, “We hope [Ivanpah] can serve as a proof point and spur further investment in this exciting technology.” Google’s contribution helped close financing for the final $2.1 billion price tag.

Construction of the plant required precise organization and management of many moving parts. The materials alone included 42 million heliostat components, including 22 million rivets, more than 7,500 tons of steel, 1,200 miles of cable, and more than 36,000 cubic yards of concrete.

Installing the 173,500 heliostats according to schedule meant that 500 mirrors had to be delivered to the solar field every day for two years. To make this work, the team devised a special transportation system that would allow the project to meet its delivery targets.

With so much repetition at such a large scale, well-coordinated planning and innovative solutions helped create efficiencies. Equipment was redesigned in order to develop a more efficient way of augering holes and installing heliostat pylons, while allowing the project to better protect the desert landscape and reduce impact to the environment.

Construction of the power towers and boilers represented significant first-of-a-kind elements that tested engineering teams and craft labor. The towers were assembled in sections and in multiple assembly areas in order to maintain the schedule, while the boilers were built in ten 90-ton structures in a common area. Boiler sections were carefully lifted into place with specialized cranes (Figure 3).

|

| 3. Center of attention. The power towers generate steam in 2,100-ton boilers heated by concentrated sunlight. Here, one of the boiler walls is being lifted into place. Courtesy: Bechtel |

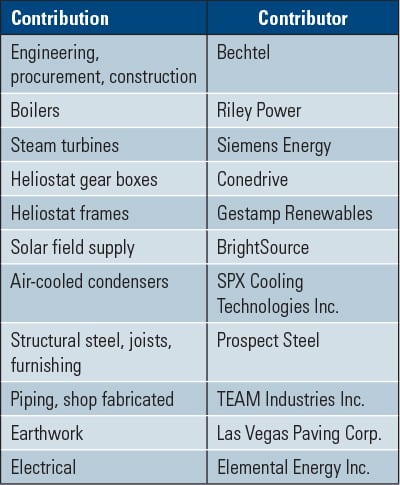

A partial list of vendors and contractors is given in Table 2.

|

| Table 2. Partial list of suppliers and contractors for Ivanpah project. Source: Bechtel, NRG |

Environmental Impact

Ivanpah was designed from the beginning to minimize impact on the desert ecosystem despite the large size of the facility. In addition to revising the tower designs to shrink the footprint and relying on dry cooling, the majority of the 170,000-plus heliostats were mounted in place with little or no grading or even concrete foundations. Instead, the supports were simply placed into the desert soil as is. While a lot of holes still needed to be drilled, it avoided what would have amounted to a “clear-cut” wiping out thousands of acres of habitat.

Yet more obstacles were to come. By the spring of 2011, with construction under way, it became clear that there were many more desert tortoises occupying the site than anticipated by the BLM’s original Biological Opinion for the project. BrightSource had already expended considerable effort and expense finding and relocating the tortoises. Nearly 16 miles of fencing had to be installed around the project as part of the relocation effort, with another 50 miles being installed off-site as a mitigation requirement (this latter project is ongoing). In addition, more than 7,000 acres of tortoise habitat were purchased, and endowments were posted for the long-term management of these lands. BrightSource also employed teams of biologists (peaking at more than 160) to work alongside the construction crews to ensure the protection of tortoises (Figure 4).

But in April 2011, after the Western Watersheds Project filed a lawsuit against the BLM and the U.S. Fish and Wildlife Service (USFWS) over a determination that allegedly underestimated the impact on the tortoises, the BLM issued a stop-work order on a portion of the site that had not yet been screened for tortoises to reassess the situation.

In June, after further study, the USFWS issued a revised opinion stipulating new protective measures that would reduce impact on the tortoises. BrightSource implemented a new program to locate and protect tortoise eggs and hatchlings to help reduce juvenile tortoise mortality (up to 98% of tortoise hatchlings fail to reach maturity). The “head-start” program, as it became known, identified egg-bearing female tortoises found within the project boundary, monitored them until the eggs were laid, and then took steps to protect the nest. Once hatched, the juvenile tortoises were moved to a protected area to keep them safe from predators.

A few figures will illustrate just how much had to be overcome to deal with the tortoises. The original permit from the USFWS allowed BrightSource to encounter no more than 38 of the species. Ultimately, more than 170 were found and relocated (or will be, once of age—some hatchlings are still being protected), and more than $30 million has been spent to date on tortoise protection measures.

Going Online

First flux was achieved with Unit 1 in February 2013 and with Unit 2 and 3 in May and June, respectively. Unit 1 achieved the first sync to the grid in August, and the last heliostat was in place in October. Full operation of all three units was achieved that December.

The project had an exemplary safety record: 31 months of work and 7.3 million man-hours without a lost time accident, despite the great size and complexity of the plant. Said Toby Seay, president of Bechtel’s power global business unit, “From completing several first-of-a-kind construction elements to protecting the environment, the project was a successful collaboration among everyone involved.”

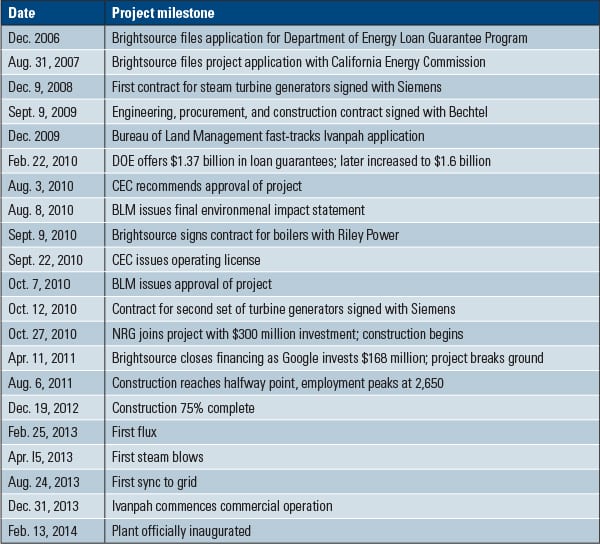

A full project timeline is shown in Table 3.

|

| Table 3. Key milestones for Ivanpah. Construction was completed in just 31 months despite the size and complexity of the project. Source: NRG, Bechtel, CEC |

Moving Forward

To say the project partners were proud of the accomplishment in bringing Ivanpah online would be an understatement.

Power plant inaugurations can be lavish affairs, but few are attended by sitting secretaries of energy, and fewer still by Grammy-nominated rock bands and dozens of media representatives (including this author). Yet such was the attention Ivanpah had garnered by this spring that all of the above witnessed the ribbon-cutting (Figure 5).

“This is an exciting culmination of many years of hard work by all of our partners at Ivanpah,” said David Ramm, chairman and CEO of BrightSource. “The completion of this world-class project is a watershed moment for solar thermal energy.”

Tom Doyle, president of NRG Renew, said, “We see Ivanpah changing the energy landscape by proving that utility-scale solar is not only possible, but incredibly beneficial to both the economy and in how we produce and consume energy.”

Secretary of Energy Ernest Moniz was effusive in his praise of the project. “Investing in clean energy isn’t a decision that limits our economic potential—it’s an opportunity to lead the global clean technology markets that are forming right now,” he said. “We simply can’t afford to be at the back of the train—we have to be at the front, leading the world in these industries.”

Though the DOE’s support of renewable energy projects has come under fire, the department was happy to tout the success at Ivanpah. “This project was made possible by the successful public-private partnership between the Department of Energy and the project sponsors,” Peter Davidson, LPO executive director, said in a statement. “Through partnerships like this, we can continue to build an innovative clean energy economy in the U.S.”

As large as the guarantee was, Ivanpah represents just a portion of the 2.8 GW of LPO-financed large-scale solar (CSP and photovoltaic [PV]) that is currently operating or under construction. Though the LPO program has been controversial because of a handful of high-profile busts—most notably solar PV manufacturer Solyndra—it has on the whole been highly successful in nurturing renewable energy projects, with an approximately 98% success rate.

The LPO currently oversees a portfolio of more than $30 billion that supports more than 30 closed and committed projects. Most notable here are five large CSP projects that are online or will come online this year: Ivanpah; Abengoa’s Solana in Gila Bend, Ariz., and Mojave Solar One in Barstow, Calif.; NextEra Energy Sources’ Genesis Solar in Blythe, Calif.; and SolarReserve’s Crescent Dunes in Tonopah, Nev. Collectively, these projects—totaling about 1.3 GW in capacity—received nearly $6 billion in total LPO loan guarantees.

Questions Remain

Yet concerns about big CSP projects like Ivanpah linger.

The inaugural tents at Ivanpah had scarcely been taken down before some analysts were questioning whether the demand for CSP has dried up, at least in the U.S., and whether the environmental costs of these vast projects are too great.

BrightSource explored plans for two separate two-unit, 500-MW projects in California, both of which have now been suspended. One, at Hidden Hills, about 30 miles northwest of Ivanpah, was suspended in April; BrightSource cited “changing dynamics in the California energy markets” for the decision, according to a statement. The other project, Rio Mesa in Riverside, was cancelled last year after repeated difficulties in permitting.

A third 500-MW project, which BrightSource is developing with Abengoa in Riverside, the Palen Solar Electric Generating System, is still under consideration by the CEC, but the application has been delayed by concerns over bird deaths. That project was initially permitted as a parabolic trough generator, but BrightSource wants to change the design to a two-unit solar tower station.

Whether those deaths—which have occurred at Ivanpah as birds have been singed flying through the concentrated solar flux—is a problem, depends on whom you ask. It’s undisputed that several dozen to several hundred birds have been killed over the past year or so, and this was enough to create a mild kerfuffle in the media after Ivanpah’s inauguration.

Some of that attention was surely directed by critics of renewable energy subsidies, and it’s worth noting that domestic cats in the U.S. kill anywhere from 1.4 billon to 3.7 billion birds a year, according to a recent USFWS study. (And this is without getting into the environmental impacts from fossil-fuel generation and climate change that Ivanpah is intended to avoid.) Still, the problem was enough to at least temporarily derail CEC permitting for Palen in December

One of the criticisms leveled against Ivanpah is its lack of thermal storage, a point with some merit. (The response from project partners has been that adding storage would have increased the already huge price tag beyond economic feasibility and lowered the plant’s overall efficiency.) Still, as thermal storage methods become more established, it would be tough to bet against CSP in the future. The Solana project uses molten salt to store about 6 hours of energy, while the Crescent Dunes plant will store about 10 hours.

Most observers expect thermal salt storage to be the model for CSP plants in the future, but it’s unlikely that further progress in that direction would be possible had Ivanpah gone bust. “Standing on the shoulders of giants” is a common expression when speaking of technological advancement, but here the giant is a literal one, not just a figure of speech.

Congratulations to BrightSource, NRG Energy, Bechtel, Google, and the project team that brought this high-profile plant to a successful conclusion. ■

—Thomas W. Overton, JD is a POWER associate editor (@thomas_overton, @POWERmagazine).

This article has been updated to correct an error in the plant’s stated water usage.