U.S. Power Heavyweights Unveil Hydrogen Power-to-Power Demonstration

Duke Energy, GE Vernova, and Sargent and Lundy will team up on a pioneering project to demonstrate an end-to-end energy system that produces, stores, and combusts 100% renewable hydrogen at Duke Energy’s DeBary solar plant in Florida.

Duke Energy on Oct. 27 said construction on the project, a “one-of-a-kind end-to-end” system, will begin later this year and could be installed within a one-year timeframe. “Duke Energy anticipates the system will be installed and fully functioning in 2024,” it said.

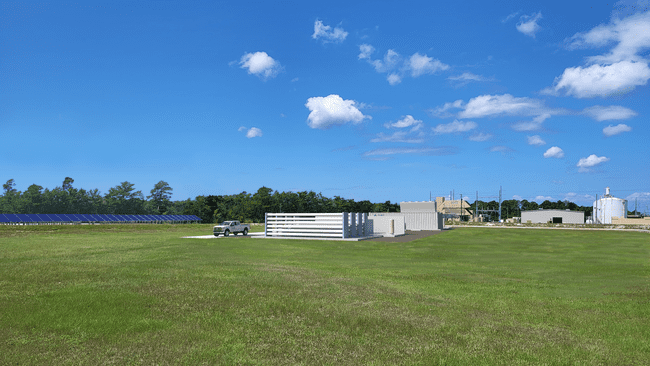

The demonstration comprises two parts: It will source hydrogen from a production facility planned at the 74.5-MW Debary plant in Volusia County, Florida., a 2020-opened solar PV farm that features 300,000 panels. The hydrogen production plant, which will utilize power from the solar farm, will run on two 1-MW electrolyzer units.

The renewable hydrogen will then be delivered to “nearby, reinforced containers for safe storage.” However, during times when energy demand is highest, the integrated system will serve as a dedicated “peaking” facility, delivering stored hydrogen to a combustion turbine (CT) that will be upgraded using GE technology to combust a natural gas/hydrogen blend or up to 100% hydrogen. “This will be the nation’s first CT in operation running on such a high percentage of hydrogen,” Duke Energy said.

A Project to Demonstrate Hydrogen’s Dispatchable Power Role

The project marks a pivotal juncture in U.S. power industry-led efforts to develop carbon-free dispatchable energy sources. Duke Energy, in a statement on Friday, underscored hydrogen’s growing role. “Readily available hydrogen is a dispatchable energy source, meaning it is available on demand. It can be turned on and off at any time and is not dependent on the time of day or the weather, like sun, wind, or other renewable energy sources known as intermittent,” it said.

“Duke Energy anticipates hydrogen could play a major role in our clean energy future,” said Regis Repko, senior vice president of generation and transmission strategy for Duke Energy. “Hydrogen has significant potential for decarbonization across all sectors of the U.S. economy. It is clean energy also capable of long-duration storage, which would help Duke Energy ensure grid reliability as we continue adding more renewable energy sources to our system.”

In addition, by introducing the country’s first end-to-end system, the project suggests a solution to one of the renewable energy sector’s most pressing challenges: ensuring consistent energy supply even when the sun’s energy is diminished while optimizing solar energy resources for extended periods of high demand. “Relying on intermittent energy sources without available dispatchable energy sources would put our future electric system at risk of having insufficient energy to serve customer demand,” Duke Energy said.

According to Duke Energy, the project will prioritize several operational features, including “safe, quiet energy generation and storage.” Cost-effectiveness is also a priority. The end-to-end demonstration “could provide cost-effective decarbonization,” it said.

The industry collaboration behind the project is also notable. Duke Energy, the nation’s biggest utility, has explored several options as part of a sustainable strategy to achieve a “net-zero” target, aiming to produce zero carbon emissions from electric generation by 2050. Sargent and Lundy, a leading engineering, procurement, and construction contractor, and GE Vernova, an original equipment manufacturer and a major international player in the gas turbine market, are deeply entrenched in efforts to enable customers to achieve decarbonized operations.

A New End-to-End Prospect

Duke Energy said the demonstration will be the first in the U.S. to integrate a full 100% hydrogen production value chain with a dedicated power output at a single site. But when it comes online in 2024, it will soon be followed by another much-watched project, Advanced Clean Energy Storage Hub (ACES Delta), which is underway in Delta, Utah, and rapidly making incremental progress. The hub, which recently received its first electrolyzers and gas separators, is slated to begin operation in 2025.

The massive 300-GWh integrated hydrogen hub, spearheaded by Chevron and Mitsubishi Power, is designed as a complete “end-to-end” solution that will capture excess renewable energy during off-peak hours from the West, convert it to renewable hydrogen via a 220-MW alkaline electrolyzer bank, and store it in two gigantic solution-mined caverns.

ACES Delta’s produced hydrogen will fuel two new Mitsubishi Power M501JAC gas turbines at the adjacent “IPP Renewed” project in Utah, which will begin operation in 2025, starting out with a fuel blend of 30% hydrogen. Mitsubishi Power plans to incrementally increase the amount of hydrogen in the fuel mix as available from the ACES Delta project to achieve a 100% hydrogen combustion volume by 2045, catering to California’s stringent mandate for carbon-free power. Mitsubishi Power told POWER it plans to conduct “100% hydrogen firing verification with a fully commercial-grade small- to mid-size gas turbine” this year. ACES Delta project partners, notably, have also suggested they are developing “several other opportunities” to produce and supply hydrogen for “customers in the utility, transportation, and industrial sectors in the western region of the U.S.”

The Duke Energy-led project also follows similar efforts around the world. Earlier this month, HYFLEXPOWER—a European Union (EU)-backed industrial-scale demonstration of integrated hydrogen power-to-power—announced it powered its Siemens Energy SGT-400 gas turbine with 100% renewable hydrogen.

The achievement is a leap for HYFLEXPOWER, a four-year CORDIS project that seeks to demonstrate the full power-to-hydrogen-to-power chain for industrial operations, including the production, storage, and re-electrification of hydrogen. The $16 million (€15.2 million) project has been ongoing since June 2020 at a converted 12-MWe combined heat and power (CHP) plant at ENGIE Solutions’ Smurfit Kappa pulp-and-paper industrial site in Saillat-sur-Vienne, France. Along with Siemens and ENGIE, partners include Centrax, Arttic, the German Aerospace Center (DLR), and four European universities. It is slated to end in April 2024.

As POWER has reported, the CHP facility was installed in 2007 using a Siemens Energy SGT-400 gas turbine and a recovery boiler to produce power. It has also produces steam, which the Smurfit Kappa paper mill uses to dry pulp from the recycling of waste paper to make new paper for cardboard. HYFLEXPOWER produces hydrogen via a 1-MW Siemens Energy electrolyzer onsite and stores the hydrogen in an “almost one-ton tank” before it is used to power the Siemens Energy SGT-400 industrial gas turbine.

SGT-400 industrial turbines typically use G30 burner technology, a radial swirler premixing design that allows for fuel flexibility and can operate up to a 10% hydrogen blend. At HYFLEXPOWER, the turbine integrates dry-low emissions (DLE) combustion technology, developed through a dedicated research and technology program at Siemens Energy’s Clean Energy Center near Berlin. During the test campaign, the team demonstrated 100% hydrogen DLE operation at SGT-400 full-pressure engine conditions with low nitrogen oxide emissions.

“No previous reference facilities are available to support the infrastructure design at the project scale for hydrogen generation, storage, and the supply at ~14000 Nm3/h,” the HYFLEXPOWER team notes. HYFLEXPOWER’s first hydrogen pilot took place in December 2022, using a mixture of 30% hydrogen and 70% natural gas. With its goal to re-electrify 100% renewable hydrogen now achieved, the team plans to expand the consortium and “extend its operation to industrial heat production and additional operational modes,” Siemens Energy said. “It is also planned to explore ways of scaling up and commercializing decarbonized electricity generation.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

Editor’s Note: This is a developing story that is actively being updated. As this story continues to unfold, POWER magazine remains dedicated to delivering comprehensive updates. Please check back for further details as they become available. Last updated: Oct. 27, 2023 at 1:30 p.m. CST.