ACES Delta's Hydrogen Electrolyzers Arrive in Big Boost for Hub's Progress

The much-watched Advanced Clean Energy Storage Hub (ACES Delta)—a project shaping up to be the largest renewable hydrogen energy hub in the U.S.—has received its first shipment of large-scale hydrogen electrolyzers and gas separators.

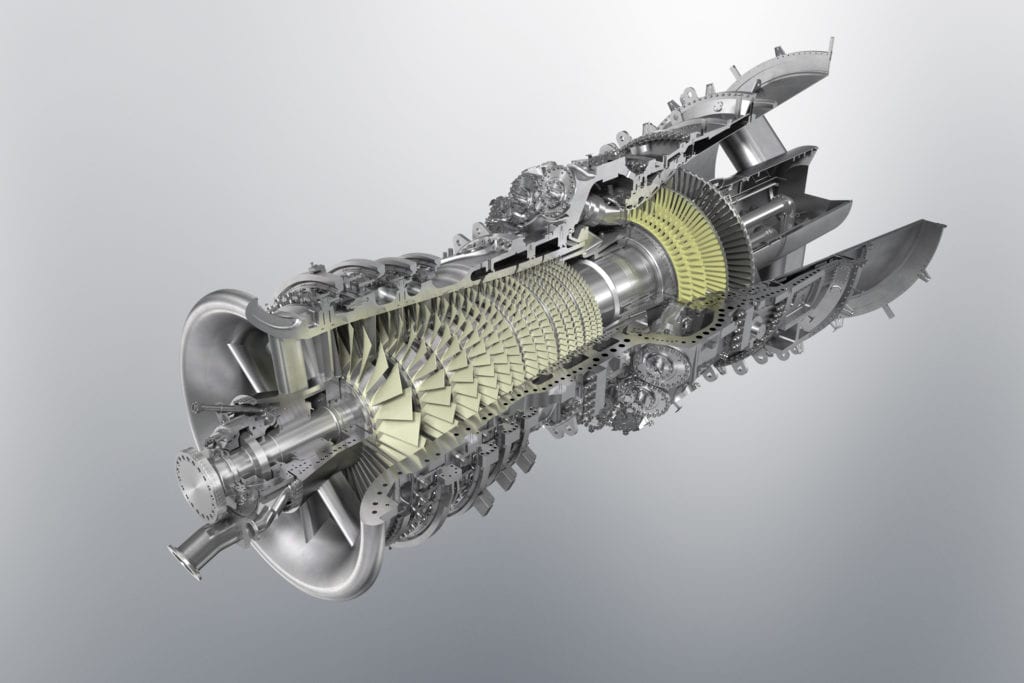

The shipment, unveiled on Oct. 25, marks the first equipment delivery for the Delta, Utah, project’s integrated Hydaptive package. Hydaptive is the trademarked name for Mitsubishi Power’s 2020-launched hydrogen product line, which comprises combined cycle gas turbines, electrolyzers, and hydrogen storage, providing a full digital and physical integration between hydrogen-capable generation assets and the integrated electrolytic-based hydrogen production plant.

The delivery indicates the massive integrated hydrogen hub is on track to come online in 2025 when its electrolyzers begin converting excess renewable energy into renewable hydrogen. Once completed, the 300 GWh system at ACES Delta Hub “will nearly double the annual production levels of clean hydrogen worldwide,” Mitsubishi Power said.

Incremental Progress for the Giant Hydrogen Hub

Mitsubishi Power partnered with Magnum Development in 2019 to kick off the development and construction of the ACES Delta hub. The hub, which is now backed by a $504 million federal loan guarantee, envisions producing up to 100 metric tonnes per day of hydrogen from water and renewable energy sources using a 220-MW high-pressure alkaline electrolyzer bank manufactured by Norwegian firm HydrogenPro.

One of the largest deployments of its type to date, ACES Delta will store that hydrogen in two gigantic solution-mined caverns sited in the only salt dome in the Western U.S, each of which can store up to 150 GWh of energy.

In May, WSP, which is providing engineering, procurement, and construction management services for the development of the two large salt cavern storage facilities, said it successfully completed drilling operation and mechanical integrity tests for the cavern wells as part of the first phase of the ACES project (ACES 1).

The project has since also garnered additional industry expertise. Initially spearheaded under a joint venture (ACES Delta LLC) between Mitsubishi Power Americas and salt-dome owner Magnum Development, Chevron New Energies in September 2023 snapped up 100% of Magnum Development LLC through a transaction with Haddington Ventures, a financial advisor for the project and Magnum’s equity sponsor.

Chevron now effectively holds the majority interest in ACES Delta. “Chevron will add tremendous strategic value as we develop a hydrogen production and storage facility,” said Craig Broussard, who serves as president, CEO, and board chairman of Magnum Development, as well as CEO of ACES Delta LLC.

Headway for Mitsubishi Power 100%-Capable Hydrogen Gas Turbine

The integrated ACES Delta storage facility is expected to provide long-term seasonal energy storage to Intermountain Power Plant’s (IPA’s) Intermountain Power Plant (IPP) near Delta, Utah, a 1986-built coal-fired plant that is slated to be repowered with two Mitsubishi Power advanced J-series power trains as an 840-MW combined cycle power plant by 2025. Project partners, however, have suggested they are developing “several other opportunities” to produce and supply hydrogen for “customers in the utility, transportation, and industrial sectors in the western region of the U.S.”

As POWER recently reported, the “IPP Renewed” project in Utah received its two new M501JAC gas turbines in August 2023. The two turbines will be capable of utilizing a fuel blend of 30% hydrogen by volume when they begin operation in 2025. Under a 20-year long-term service agreement (LTSA), Mitsubishi Power will incrementally increase the amount of hydrogen in the fuel mix as available from the adjacent ACES Delta project to achieve a 100% hydrogen combustion volume by 2045, catering to California’s stringent mandate for carbon-free power.

Mitsubishi Power on Thursday confirmed that efforts to validate high-volume hydrogen combustion are successfully progressing. “In 2018, Mitsubishi Power successfully validated the use of 30% by volume hydrogen in a large frame gas turbine combustor, and furthered this achievement in 2022 by validating 50% by volume hydrogen in a large frame combustor,” Michael Ducker, senior vice president, and head of Hydrogen Infrastructure at Mitsubishi Power, told POWER.

“Additionally, in 2022, we achieved the milestone of 100% hydrogen firing using a combustor on our small- and mid-size gas turbine.” Looking ahead, the company’s plans for fiscal year 2023 include “conducting 100% hydrogen firing verification with a fully commercial-grade small- to mid-size gas turbine located at Takasago Hydrogen Park, utilizing our Type 3 Multi-Cluster combustor,” he said.

Hydaptive Delivery Marks A Major Milestone

Delivery of ACES Delta’s large-scale electrolyzers and gas separators, key elements of its Hydaptive integrated hydrogen production plant, “marks the newest significant milestone as we move closer toward completion of the ACES Delta Hub,” said Kent Rockaway, Vice President, Hydrogen Production, Mitsubishi Power Americas on Thursday.

The 220-MW electrolyzer portion, manufactured by HydrogenPro at a production plant in Tianjin, China, includes 40 5.5-MW pressurized alkaline electrolyzers. HydrogenPro, which has signed a 10-year service and support agreement on the ACES project, suggests will now begin on-site work for the electrolyzers, with completion planned for late 2024.

At 100% load, the electrolyzers “provide a capacity for almost 100 metric tonnes per day of hydrogen production,” Ducker, who is also ACES Delta LLC’s Chief Operating Officer, told POWER on Thursday. The project, however, is still exploring how variable operations could affect output. “Getting into the realm of renewable energy and the resources required to support that amount of hydrogen production is something we are still exploring and testing,” he noted.

At 100% load, the project will also use about 200 gallons of water per minute, Ducker said. “As the project advances, more specific water consumption data will be available, but we will work diligently to make sure we are using all resources as responsibly as possible,” he added.

A key project objective entails ensuring sound economics for hydrogen production. HydrogenPro suggests its third-generation electrolyzer technology could deliver a levelized cost of hydrogen of $1.20/kg (with an assumed electricity price of $20/MWh). Ducker noted the overall project is also designed for cost-effective hydrogen production.

“ACES Delta is strategically and conveniently located. With a salt cavern, minimal pipeline, and close proximity to the end user, it is in an ideal geographic area,” he said. “We went through significant efforts to pick the best partners for this project to ensure quality delivery and the lowest cost possible. We deliberately picked the lowest cost and most commercially viable electrolyzer and competitive engineering, procurement, and construction contractors [Black and Veatch].” In addition, “the project intends to use renewable energy from a variety of sources, including curtailed renewables,” Ducker said.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).