With artificial intelligence (AI) causing a surge in electricity demand across the world, power capacity and availability are more vital than ever. The race is on to build more generation assets. In the meantime, power producers are intent on eking out every MW possible from their generation assets, and therefore, they are determined to minimize unscheduled downtime at these facilities. This requires that attention be paid to the many factors that can take a facility offline.

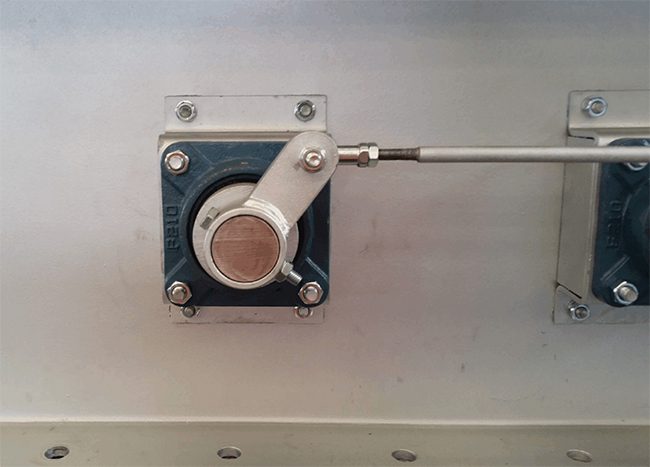

Take the case of the dampers that control the flow of preheated air into the turbine’s combustion processes (Figure 1). Some power plants have experienced difficulties when attempting to open these dampers. As a result, hot air quickly dries out the lubricant in the steel damper bearings. This causes them to seize. The best solution to this problem is to replace the original steel bearings with material that can withstand the heat.

|

|

1. Four-bolt, self-aligning, cast iron flange blocks with Graphalloy inserts were implemented to resolve bearing failure issues that stalled combustion processes at an Italian facility. Courtesy: Graphite Metallizing Corp. |

At a refinery project in Italy, Graphalloy bearings from Graphite Metallizing Corp. of Yonkers, New York, were installed to eliminate continual maintenance issues with the steel bearings in the dampers. These new damper bearings have since run for several years without causing the refinery’s power plant any further issues.

Regular Bearing Failures

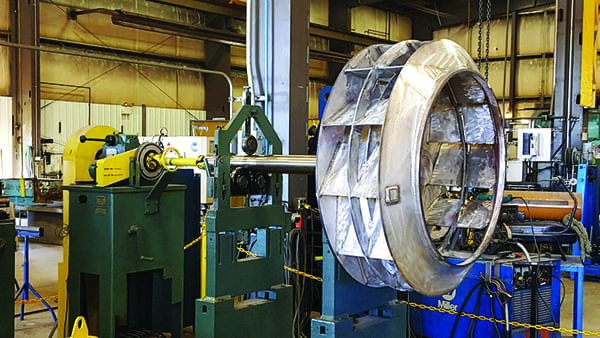

A major engineering, procurement, and construction (EPC) company that has built many refineries, fertilizer complexes, polymer plants, fuel, and chemical facilities around the world, contacted industrial machinery manufacturing firm Dama Energy Services of Italy to help solve a damper problem. Dama Energy Services operates in onshore and offshore oil and gas, power generation, and renewable energy markets. It specializes in developing detailed design and construction of metal carpentry structures, as well as offering assembly services for any type of mechanical system.

At the refinery in Italy, dampers play a vital role in the power control units that run as part of the refining process. The dampers are there to open and close the dry air and flue gas flow to the treatment plants. To accomplish this, they must be able to withstand loads of 440 pound-feet of torque at a speed of 25 revolutions per minute and at temperatures up to 400C (750F). These dampers were in continuous use—every 10 minutes, they rotated 90 degrees as part of airflow control.

Unfortunately, temperatures were commonly at the upper range of the process and sometimes exceeded it. As a result, the SKF ball bearings operating within the dampers were subjected to excessive heat levels that went beyond their design parameters. This resulted in bearing failures.

Maintenance personnel at the refinery often had to replace these bearings. As well as adding to the maintenance and equipment procurement budgets, outages due to damper failures proved costly in terms of revenue by interrupting refinery operations. Based on experience with similar issues, Dama Energy Services contacted an engineer at Graphite Metallizing Corp. to devise the best bearing solution to solve these damper problems.

“After analyzing the process technical specifications, I contacted Graphalloy to request bearings with temperature and rotation characteristics that would meet the project needs,” said Alfredo Mariotti, engineer and technical director at Dama.

The solution in this case turned out to be Graphalloy Type 845 self-aligning flange block assemblies, with copper-grade inserts (Figure 2). Dimensionally interchangeable with the SKF ball bearings, these new components allowed the damper paddles the movement they needed in an environment and at temperatures where the existing ball bearings were prone to failure.

|

|

2. Bearing issues led to problems in opening, closing, and rotating the dampers controlling the flow of dry air and flue gas. Courtesy: Graphite Metallizing Corp. |

Dama Energy Services installed the new damper components at the refinery using the new materials. After a couple of months of trouble-free operation, more of these damper assemblies were ordered to be installed more broadly across the facility, reported Mariotti.

Graphite Impregnation

As a material, Graphalloy is composed of graphite that is impregnated with different alloys. “We can mix and match the different graphite and metallic combinations based on the needs of the specific applications,” said Eric Ford, vice president at Graphic Metallizing Corp. “We manufacture over 150 grades of this graphite-based material. Our specific recommendations depend on the needs of the site, its environment, and the processes running.”

Available grades can withstand temperatures as high as 1,000F in an oxygen environment, and much higher in an inert environment. Since the graphite/metal alloy materials are self-lubricating, non-galling, and have a low coefficient of friction, they don’t require grease or oil that can dry out or burn off under extreme heat. Not only does this reduce maintenance requirements, it also allows the dampers to work under conditions where lubricants or plastics cannot. In petrochemical plants, for example, there is always a concern about materials used in a plant process that might dissolve the lubricants.

At the other end of the spectrum, bearings made of graphite/metal alloys also work well in cryogenic applications such as in liquefied natural gas (LNG) pumps. They can maintain their self-lubricating properties without congealing or solidifying. If a pump runs dry, for example, they will maintain lubrication without galling or seizing.

Component Longevity and Reliability

In this era of high capacity and maximum efficiency, those operating power generation assets must pay attention to the longevity and reliability of all components in use. One small failure can bring down the entire facility. Where one or more parts are found to fail repeatedly, it is up to owners and operators to find a suitable replacement—one that performs well and eliminates the need for continual troubleshooting or babysitting.

“Some of our bearings have operated for up to 20 years without maintenance,” said Ford. “We have many standard designs, but most of our products are custom designed for the unique requirements of specific applications.”

Engineers at Dama Energy Services confirmed this claim based on their experience at the refinery in Italy. “Graphalloy materials are essential because they eliminate the need for maintenance on rotating parts exposed to high temperatures,” said Mariotti. “We have been using them for many years. They are reliable and are still running well since we installed them.”

—Drew Robb (drewrobb@sbcglobal.net) has been a full-time freelance writer for more than 25 years specializing in engineering and technology.