Solar Farm at a Landfill Site Brings New Meaning for Waste to Energy

|

The Mount Olive project in New Jersey is a model for turning a brownfield site into a “brightfield,” supporting cleaner power generation and providing a wealth of benefits for the local community.

The U.S. Environmental Protection Agency (EPA) has reported that there are more than 10,000 closed landfills in the U.S. Reclamation of these sites is big business; many locations have been remediated and turned into parks, gardens, and well-known golf courses across the country.

Landfills also can host energy projects. Research groups, including the World Resources Institute, have said U.S. cities and counties announced more than 20 brownfield solar power projects in 2021, turning these sites into “brightfields,” with more than 200 MW of electricity generation capacity. More such projects are on the way, with additional tax credits available for landfills and other brownfield sites through the Inflation Reduction Act.

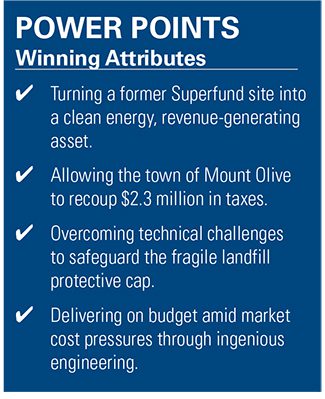

The EPA is a backer of such installations, realizing the benefits of putting solar arrays on landfills, old coal mines, Superfund sites, and closed industrial facilities. One such project is the 25.6-MW Mount Olive installation in New Jersey. When completed early in 2023, it was the largest landfill solar project in North America, with power production supporting the state’s goal of increasing generation from renewable energy resources.

“Only a small fraction of the 10,000 closed landfills across the U.S. have been converted into solar fields,” said Chris Ichter, executive vice president at CEP Renewables, owner of the property and the group responsible for maintaining the landfill cap. “The unique structure we used to implement this project now serves as a model that can be leveraged to redevelop more closed landfills into revenue-producing assets that facilitate cleaner air, tax revenue, jobs, and more affordable energy for residents.”

Mount Olive has been touted by the solar power industry for the redevelopment process, along with the design and construction execution, used to turn the former landfill into an energy showcase. It’s a landmark project for New Jersey, and now a POWER Top Plant award winner for renewable energy.

Overcoming Construction Challenges

There are challenges to remediating and redeveloping a brownfield site, and several specific challenges when it comes to installing a solar array at such a location. Closed landfills are usually not suitable for traditional redevelopment, due to containing hazardous materials. That means putting solar modules on these sites requires a different kind of installation, with a ballasted system that doesn’t drive foundations deep into the ground, where the system could pierce the landfill cap and disturb the waste underground.

A landfill settlement analysis is a critical step. Builders must ensure that the design and construction process is adequate for installing the solar array atop the landfill, while avoiding damage to its protective layer. The settlement and stability of various sections of the landfill are determined through this analysis, which helps specify which locations are best for the ballast, racking, modules, and electrical equipment. Construction also needs to allow for access to the site for ongoing landfill operation and maintenance activities.

|

|

1. Terrasmart, the racking and mounting provider for Mount Olive, had experienced rising costs for concrete, so the tilt of the solar array at the site was minimized in order to reduce the amount and size of the ballast blocks. Courtesy: CS Energy |

All of that came into play at Mount Olive, and the size of the project meant developers had to keep a close eye on product costs. Terrasmart, the racking and mounting provider, had experienced rising costs for concrete, which affected the cost of its ballast blocks. The design team worked to minimize the tilt of the solar array (Figure 1) in order to reduce the amount and size of blocks needed, but the builders still needed to ensure high energy yields from the solar array.

Because the site is subject to cold weather conditions for part of the year, the solar array tilt can’t be too low; that would allow snow to pile up and put stress on the racking system. And as noted earlier, that’s particularly important for projects such as Mount Olive, because the sensitive landfill cap can’t be impacted by what’s happening on its surface.

Terrasmart, a company with more than 20 GW of solar deployed across 4,900 systems—and years of experience in solar landfill development—is known for providing solar racking technologies that provide solutions for projects covering all types of terrain. The company leveraged its experience on several other large-scale landfill solar projects in cold weather locations, and designed and engineered its GLIDE ballasted mounting solution for Mount Olive. This involved several studies of the site, from looking at wind impacts to analyzing the potential of solar power generation, to determine the optimal tilt and ballast size to help CEP meet its project budget and energy production goals, all while ensuring the sensitive landfill cap was protected in order to prevent any release of hazardous contaminants.

Terrasmart value-engineered the racking solution around three considerations: the market cost for concrete had increased by 10%; low tilt angles would be needed to minimize the weight of the ballasts; sufficient tilt was needed to allow for the snowpack to slide off the racks. By optimizing its GLIDE ballasted racking, Terrasmart delivered a 50% reduction in the cost of the blocks. In addition, CS Energy, an industry leader with more than 12 years of landfill solar installation experience and the lead contractor for Mount Olive, leveraged Toshiba Mitsubishi Electric Industrial Systems Corp. (TMEIC) and partner Lindsay Precast to help reduce on-site labor and streamline schedules, while maintaining a high level of quality through its steel skid manufacturing and integration.

Innovative Equipment and Quality Control

Solar farm projects atop landfill sites often require innovative fixed-tilt, ballasted mounting solutions, another solution to lessen the risk of damaging the landfill cap. Lindsay Precast, a company that has deployed more than 4,500 prefabricated solar skids, was hired by TMEIC to integrate TMEIC’s Solar Ware Ninja inverters and medium-voltage transformer onto Lindsay’s non-penetrating galvanized steel skids.

Lindsay Precast’s scope of work included the design and engineering of the steel skid, equipment storage/integration, wiring/terminations, and testing, all of which took place in a Lindsay weather-controlled facility (the company has nine such sites). TMEIC and CS Energy leveraged Lindsay’s capabilities to reduce on-site labor, streamline delivery schedules, and improve quality control to positively impact the project. Lindsay Precast has completed several projects with Terrasmart, and Mount Olive marks the company’s seventh project with CS Energy, including the Cuyahoga Landfill solar project that came online in 2018 and was the first-of-its-kind in Ohio.

Boviet Solar, a module manufacturer, supplied 57,000 450-W panels for the Mount Olive project. Jersey Central Power & Light (JCP&L), a subsidiary of FirstEnergy Corp., completed the grid connection for Mount Olive in February of this year. CEP Renewables is leasing the site to NJR Clean Energy Ventures, which will own and operate the facility long term, with the electricity delivered through FirstEnergy’s transmission lines.

“FirstEnergy and JCP&L are committed to supporting the global energy transition to renewable resources, and we are pleased to have worked with CEP Renewables to connect this innovative solar project to the grid and enable the delivery of clean energy to local communities,” said Jim Fakult, president of New Jersey operations for FirstEnergy, when the project was connected to the grid.

“NJR Clean Energy Ventures is committed to building a clean energy future with projects like the Mount Olive solar field,” said Steve Westhoven, president and CEO of New Jersey Resources. “By repurposing landfills and other underutilized spaces to produce clean, renewable energy, NJR is helping to power a bright, sustainable future, today and delivering clean energy innovations that drive New Jersey toward our clean energy goals.”

Redevelopment and Tax Structure

CEP’s team of landfill and brownfield experts negotiated a novel public-private partnership with the local community and the New Jersey Department of Environmental Protection (NJDEP) that enabled CEP to purchase the landfill as part of a redevelopment and tax lien foreclosure process. In the agreement, CEP agreed to pay the back taxes to the Mount Olive Township, in Morris County, over time in addition to redeveloping the land into a tax revenue-producing solar field.

Officials said the project enables the township to not only recoup about $2.3 million in back taxes, but also benefit from future taxes related to the property. The landfill operated for about 15 years, but in the early 1980s the owner went bankrupt, the property was abandoned, and the landfill closed. The township wanted to redevelop the site, but commercial developers balked at a purchase due to environmental restrictions and state environmental requirements. The NJDEP eventually determined it would be feasible for a solar farm, and the township put together a redevelopment plan that permitted a solar array. Mount Olive is among several landfill or brownfield solar projects either in service or being developed by CEP Renewables, which has been working on landfill solar projects for more than a decade.

“With global expertise and proven remediation, engineering, and permitting strategies, CEP Renewables is a premier solar developer,” said Robert Pohlman, vice president of corporate strategy at NJR Clean Energy Ventures, also known as CEV. “NJR Clean Energy Ventures has long supported state policy to prioritize underutilized land and bring complex solar projects—from conception to energization—to the marketplace.”

—Darrell Proctor is a senior associate editor for POWER (@POWERmagazine).