Companies Announce Advancements for Diesel-, Gas-Powered Engines

The global market for diesel- and gas-powered engines continues to grow, as manufacturing companies unveil products designed to produce power more efficiently while at the same time lowering emissions. The market also is being supported by the use of engines that can run on multiple fuels, including both renewable diesel and renewable natural gas.

Rolls-Royce, the UK-headquartered group, recently opened a new production facility for its mtu 2000 series engines in Kluftern, near Friedrichshafen, Germany. The company said relocating the assembly of the mtu 2000 is part of a modernization strategy that also will provide long-term production space for the company’s 4000 series engine. Dr. Jorg Stratmann, CEO of Rolls-Royce Power Systems, said, “Our investments are a clear commitment to the region and to our products and solutions, which are important building blocks of the energy transition in various application areas. We are convinced that, in conjunction with sustainable fuels and new technologies, the internal combustion engine will play a central role in the future. Because it’s the fuel that matters, not the engine.”

Rolls-Royce is focusing on developing engines that can run on a range of what it calls sustainable fuels, in order to reduce emissions of carbon dioxide (CO2). The company already is producing hybrid engines for the power generation space, in addition to engines for the rail and shipping industries. Rolls-Royce has said it is focused on providing power for energy systems that cannot move to complete electrification. Officials said recently that renewable diesel—hydrogenated vegetable oil, or HVO—is an important part of its strategy for decarbonization, with many of the group’s mtu brand engines already able to run on the fuel. Rolls-Royce said the use of HVO supports as much as a 90% reduction in CO2; it also reduces emissions of particulate and nitrogen oxide.

“We are doing everything we can to make the internal combustion engine climate-neutral with sustainable fuels and in combination with new technologies,” said Strattman. “But this can only be achieved if the political framework conditions are set so that alternative fuels can be successfully ramped up.”

Rolls-Royce in July announced that its mtu Kinetic PowerPack units, based on the 4000 and 1600 series diesel engines, have been approved to use renewable diesel along with other synthetic fuels. The company said that tests on the Rolls-Royce Power Systems test bench at the Liège site in Belgium showed that the use of HVO did not affect the engine’s performance during critical phases under typical load conditions. Officials said the engines using HVO performed the same as an engine using standard diesel fuels.

Rolls-Royce said the Kinetic PowerPack features a constantly rotating kinetic energy storage unit with a flywheel, a diesel engine, and a generator that doubles as an electric motor for the purpose of compensation, depending on the operating mode. The company said a synchronous generator acts as an electric motor in this operating mode, driving a flywheel in the kinetic energy storage unit, “which is laid out as an electric machine with double rotor system, which makes energy available in the event of a power outage.”

Germany’s MAN Energy Solutions recently said its first ME-GA Otto-cycle engine has completed gas trials in a liquefied natural gas (LNG) carrier built by Hyundai Samho Heavy Industries for Knutsen OAS Shipping, a Norwegian company. “This successful gas trial is a very important milestone in the development of the ME-GA engine,” said Bjarne Foldager, head of two-stroke business at MAN Energy Solutions. “We developed this engine for easy application to most contemporary LNG carrier designs and, indeed, all ME-GA orders to date have been exclusively for this segment.” MAN said the Knutsen ME-GA engine is equipped with exhaust gas recirculation (EGR), which reduces methane-slip emissions compared to first-generation Otto-cycle engines without EGR.

“We have had more than 260 orders for the ME-GA since its launch in May 2021 and our orderbook contains ME-GA engine orders for ship deliveries stretching all the way into 2027,” said Brian Østergaard Sørensen, vice president and head of research and development for the two-stroke business at MAN Energy Solutions. “EGR as standard enables the ME-GA to significantly reduce emissions, while simultaneously improving fuel efficiency and operation in both gas and fuel-oil operation.”

Thomas S. Hansen, head of promotion and customer support at MAN Energy Solutions, said the ME-GA has continued to evolve since development of the technology began in 2018. Hansen said the “completion of sea (trials) and gas trials marks another significant step in its timeline as it approaches its commercial debut.” The engine is designed for LNG carriers with the ability to “boil off” gas as a source of fuel. The company said the ME-GA “joins the well-established ME-GI diesel-cycle engine in MAN Energy Solutions’ two-stroke-engine portfolio, which now offers both low- and high-pressure, dual-fuel solutions for operation on LNG.”

|

|

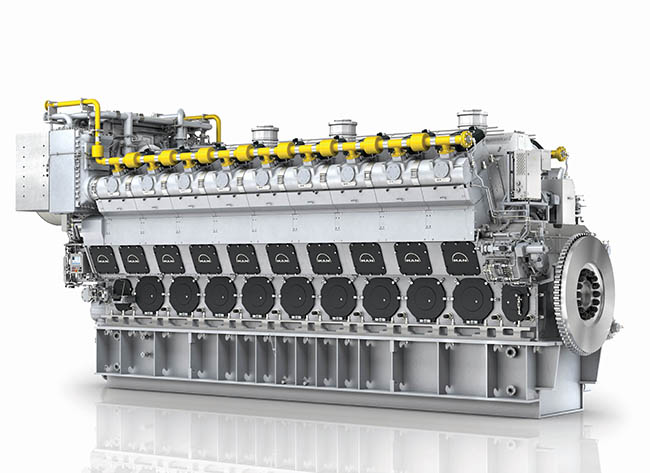

1. Three 18V51/60DF engines (shown here) from MAN Energy Solutions, along with one of the company’s 8L51/60DF units, will supply power for a solar-glass production plant on the island of Borneo, in the Malaysian state of Sabah. Courtesy: MAN Energy Solutions |

MAN Energy Solutions also recently announced that four of the company’s 51/60DF dual-fuel engines will supply power for a solar-glass production plant on the island of Borneo, in the Malaysian state of Sabah. The order includes three 18V51/60DF engines (Figure 1), and one 8L51/60DF engine. The engines will work together as a generator set to provide 65 MW of generation capacity for the industrial facility, which is currently under construction near the city of Kota Kinabalu in northern Borneo.

Martin Chmiela, regional sales head, Power Plants, Asia-Pacific at MAN Energy Solutions, said, “Our dual-fuel engines are ideally suited for the reliable and decentralized power supply of industrial plants in remote regions and on islands. This power plant will be able to run on both low-emission natural gas and liquid fuels, offering the greatest possible security of supply.” The company said the four engines will mainly run on low-emission natural gas, in the form of compressed natural gas (CNG). CNG, which is mostly methane, is compressed to less than 1% of the volume that natural gas occupies at normal atmospheric pressure. CNG is more easily transported by ship and truck, which makes it suitable for supplying remote areas that do not have their own natural gas or LNG infrastructure.

Indiana-headquartered Cummins recently announced a new line of 175-kW and 200-kW natural gas–powered generator sets for use in North America. The company said the new gensets include features such as:

- ■ Rugged six-cylinder spark-ignited QSJ8.9G gas engines for reliable power that can respond quickly to load changes.

- ■ The PowerCommand 2.3 control for automatic remote starting/stopping, precise frequency and voltage regulation, alarm and status message display, and output metering compliant with the National Fire Protection Association (NFPA) 110 Level 1 standard.

- ■ A standard cooling package that provides reliable running up to 122F.

- ■ An enclosure incorporating special designs to deliver quiet operation in a small footprint.

The new generator sets are a part of Cummins’ investment in new and sustainable technologies as part of Destination Zero, the company’s strategy to reach zero emissions across its products. “The new 175-kW and 200-kW natural gas generator sets offer our customers industry-leading power density and are engineered to offer exceptional performance and consistent reliability as well as to meet customers’ power requirements, all in a more compact footprint,” said Ignacio Gonzalez, executive director of the company’s Power Systems division. The company said the gensets could be used to provide reliability and versatility for stationary standby low-kWe applications such as commercial and government buildings, public infrastructure, water/wastewater management plants, healthcare facilities, manufacturing sites, and more.

|

|

2. The Brussels-West data center in Aalst, Belgium, will feature a Caterpillar standby power solution. Six Caterpillar 3516B diesel gensets, which will burn 100% hydrogenated vegetable oil, or HVO, will provide backup power for the site. Courtesy: Caterpillar |

Texas-headquartered Caterpillar in late June said LCL Data Centers, which operates data centers in Belgium, commissioned Caterpillar’s 13.5-MVA standby power solution for use at its LCL Brussels-West data center in Aalst (Figure 2). The unit will operate on 100% HVO. LCL said it will be the first data center in Belgium to use biofuels for the generation of standby power. The Caterpillar product consists of six of the company’s 3516B diesel generator sets.

“With our deep roots in Belgium, we are committed to supporting environmentally responsible initiatives that create a better world,” said Laurens van Reijen, managing director of LCL. “Our collaboration with Eneria [the local Caterpillar dealer] and Caterpillar has demonstrated the viability of HVO100 in our standby power systems. We’re strongly committed to becoming carbon-neutral by the end of this decade, and we’ve launched numerous initiatives across our operations to help us achieve this goal.”

Tim Bisson, director of Eneria Belux, which specializes in renewable energy and emergency power installations in Belgium, said his group “tested the operation of Cat generator sets with traditional diesel, HVO100, and a blend of these fuels. We concluded that the power and reactivity performance of the generators remained the same regardless of the fuel used.”

Austria-based INNIO recently said its Waukesha mobileFLEX engine portfolio, comprised of engines and gensets, now includes advanced Engine System Manager (ESM2) controls and an enhanced piston. The upgrades reduce the emissions and operating costs of equipment used in oil fields and for drilling rigs.

The company said the Waukesha mobileFLEX engine is a natural gas–powered alternative to diesel-fueled units. INNIO said the engines and gensets operate on a range of field gases without derate, and can be used “in a variety of altitude and temperature applications, and provide transient performance with diesel-like load capacity, handling up to 65% load steps and 100% load shed.” The company said the optimized piston “reduces emissions of regulated pollutants such as carbon monoxide, volatile organic compounds, and formaldehyde.”

The company said Waukesha engines running on 100% field gas from producing wells are providing power for drilling rigs in West Virginia, offsetting the use of 2,000 gallons of diesel fuel daily. “These improvements will exceed operator and contractor expectations,” said Jason Padilla, vice president of Product Management and Marketing for INNIO’s Waukesha brand. “The new controls and piston enhancements have been specifically designed to deliver the level of engine performance required by drilling applications. Our vision is that operators and contractors, when using 100% natural gas, can achieve the same engine performance they’d expect from a diesel engine while saving on fuel costs and lowering emissions.”

—Darrell Proctor is a senior associate editor for POWER (@POWERmagazine).