Nucor and Helion Target 2030 for Utility-Scale Fusion Power Plant

Nucor Corp., a manufacturer of steel and steel products, and Helion, a fusion energy company, are collaborating to develop a 500-MW fusion power plant to supply baseload electricity to a steelmaking facility. The companies are working together to set a firm timeline, saying they are “committed to beginning operations as soon as possible with a target of 2030.” Nucor said it is making a direct investment of $35 million in Helion to accelerate fusion deployment in the U.S. It claims this is the first fusion energy agreement of this scale in the world, which it expects to “pave the way for decarbonizing the entire industrial sector.”

“Nucor continues to position itself as a leader in developing clean energy solutions to decarbonize the industrial sector. This agreement with Helion, along with recent investments in clean energy, can change the entire energy landscape and forever change the world, embracing a clean energy future we could have hardly imagined a few years ago,” Leon Topalian, chair, president, and CEO of Nucor, said in a statement. “We believe in the technology Helion is building and are proud to make this investment.”

An Innovative Fusion Power Process

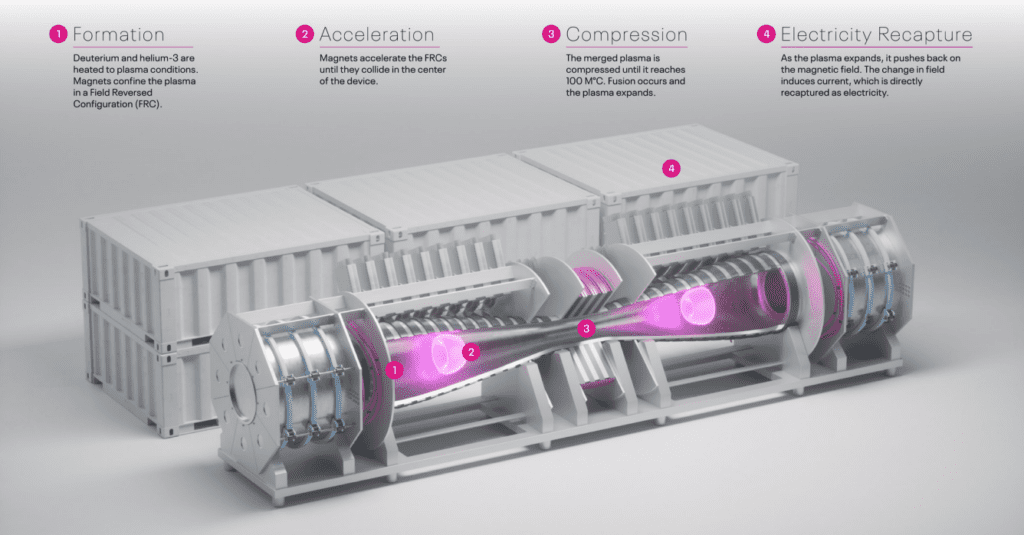

Helion’s technology involves raising fusion fuel to temperatures greater than 100 million degrees Celsius in a fusion generator and directly extracting electricity using a high-efficiency pulsed approach. According to the company, deuterium and helium-3 fuel is heated to plasma conditions while magnets confine the plasma in a “Field Reversed Configuration (FRC).” Magnets accelerate two FRCs to 1 million miles per hour from opposite ends of the device so they collide in the center.

When the FRCs collide, they are further compressed by a powerful magnetic field until they reach fusion temperatures (greater than 100,000,000C). At this temperature, the deuterium and helium-3 ions are moving fast enough to overcome the forces that would otherwise keep them apart and they fuse. This releases more energy than is consumed by the fusion process.

As new fusion energy is created, the plasma expands. As the plasma expands, it pushes back on the magnetic field from the machine’s magnets. By Faraday’s Law, the change in field induces current, which is directly recaptured as electricity, allowing Helion’s fusion generator to skip the steam cycle.

Helion says its approach is different from other fusion power concepts in three significant ways. First, it uses a pulsed, non-ignition fusion system. “This helps us overcome the hardest physics challenges, build highly energy-efficient devices, and allows us to adjust the power output based on need by adjusting the pulse rate,” the company explains.

The second difference is that Helion’s system is built to directly recover electricity. Similar to regenerative braking in an electric vehicle, Helion’s system is designed to recover all unused and new electromagnetic energy efficiently. “Other fusion systems heat water to create steam to turn a turbine, which loses a lot of energy in the process,” the company says.

Lastly, Helion uses deuterium and helium-3 as fuel. Deuterium-helium-3 fusion results in charged particles that can be directly recaptured as electricity. “This helps keep our system small and efficient, allowing us to build faster and at a lower cost. This fuel cycle also reduces neutron emissions, substantially reducing many of the engineering challenges faced by users of deuterium-tritium fusion fuel,” Helion notes.

Successful Prototypes

Helion has constructed six prototypes over the years. Its most recent—Trenta—was completed in 2019. The company said it ran nearly every day for two years. It reportedly completed 10,000 high-power pulses and operated under vacuum for 16 months. “With Trenta, Helion became the first private organization to reach plasma temperatures of 100 million degrees Celsius (9 keV),” the company says. After successful test campaigns, Helion stopped operating Trenta in January 2023.

It is now focused on building its seventh fusion prototype, called Polaris. According to the company, Polaris is designed to demonstrate the production of a small amount of electricity. It will have higher magnetic field strength and an increased repetition rate compared to Trenta. Expectations are for Polaris to begin operations by early 2024.

Helion also touts several other technical milestones it has achieved. Among them, the company claims its magnets run at greater than 90% energy efficiency. Furthermore, Helion says it has achieved compression fields greater than 10 Tesla, and sustained plasmas with lifetimes greater than 1 millisecond. “With every machine we build, we learn more about the capabilities of our science and technology. With rapid iteration and testing, we have been able to learn quickly and apply what we’ve learned to our next machines,” it says.

A Promising Future for Fusion Power

Earlier this year, Microsoft signed a power purchase agreement with Helion to buy electricity from the company’s first commercial fusion power plant. That unit is expected to produce at least 50 MWe after an initial ramp-up period and is projected to come online by 2028.

“We’re passionate about helping the world reduce its dependence on carbon-based energy sources with abundant, clean fusion power. We are excited to partner with Nucor, a leader in decarbonization in the steel industry,” Helion CEO David Kirtley said in a statement announcing the collaboration with Nucor. “A project like this is only made possible by working with a forward-looking company like Nucor, which is committed to decreasing its carbon emissions.”

Said Topalian, “This project marks a tremendous milestone in the potential for the use of nearly limitless clean electricity for industrial manufacturing. By entering this agreement, we are demonstrating our commitment to be the cleanest steel producer in the world, while setting an example for all manufacturing companies.”

—Aaron Larson is POWER’s executive editor (@POWERmagazine).