A hydroelectric facility that first came online in 1903 stands as a testament to early 20th-century hydroelectric engineering. Although much of its original structure and machinery remains in service today, a recent breaker upgrade illustrates how thoughtful modernization and modern equipment built “like it used to be” can sustain aging infrastructure.

Construction of the Bulls Bridge Hydroelectric Plant in New Milford, Connecticut, began in 1902. When the plant entered operation the following year, it became the first commercially viable hydroelectric power plant on the Housatonic River.

|

|

1. Bulls Bridge Hydroelectric, which first came online in 1903, stands as a testament to early 20th-century hydroelectric engineering. Courtesy: National Breaker Services |

Now, almost 125 years later, Bulls Bridge continues to function as a run-of-the-river hydroelectric facility (Figure 1) that utilizes its original turbines, penstocks, and canal systems. In doing so, Bulls Bridge delivers about 8.2 to 8.4 MW of generation at full capacity, with a discharge capability of 1,200 cubic feet per second. The plant annually generates about 30.8 GWh of power, ranking it third in hydroelectric output, and 38th overall among Connecticut power plants of all types.

What truly distinguishes Bulls Bridge is its continued operational relevance. The hydroelectric plant stands as a testament to early 20th-century engineering, maintaining much of its original structure and machinery.

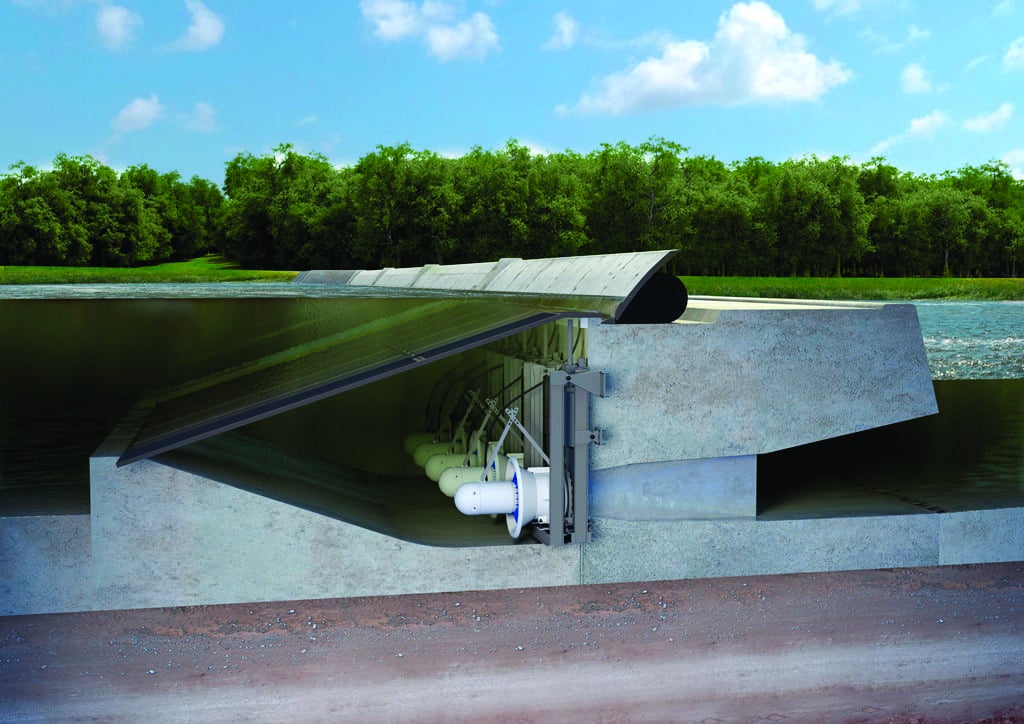

The plant today utilizes six horizontal double-runner Model F-1 Francis turbine units that were originally installed in 1903. Each unit is coupled to General Electric generators (one of those units has replaced the original equipment). The turbine-generator units are fed by water routed through a power canal that is just more than two miles long, with water carried through 420-foot-long penstocks that take the water under about 105 feet of hydraulic head down to the powerhouse.

|

|

2. The Bulls Bridge plant utilizes six original Francis turbine units installed in 1903, each coupled to General Electric generators. Courtesy: National Breaker Services |

While the turbine-generator units (Figure 2) were performing as intended, one area that required retrofitting was the downstream circuit breakers. These devices connect or disconnect the generator from the broader electrical system, provide isolation for maintenance, and protect the generator against internal faults such as stator or rotor failures, as well as against abnormal operating conditions like overcurrent, overvoltage, or unbalanced loads.

However, older breakers, such as oil, air-magnetic, or air-blast types, can become unreliable as contacts erode, insulation degrades, and maintenance costs rise. Today, these types of breakers are considered outdated due to modern safety standards and advances in breaker technology.

|

|

3. For the retrofit, National Breaker Services was called in to replace all six breakers with draw-out style vacuum circuit breakers. Courtesy: National Breaker Services |

Because of these factors, the 1903-era breakers (Figure 3) were replaced with updated designs that utilize advanced vacuum interrupter technology. A vacuum circuit breaker interrupts current by separating contacts in a sealed vacuum chamber, where the arc is quickly extinguished because there are no gases or materials to sustain it.

Modern breakers have the added benefit of being virtually maintenance-free and safer to operate. Replacing the breakers also ensures the system complies with present-day codes and utility interconnection requirements.

|

|

4. National Breaker Services removed the old breakers at the hydroelectric facility, and installed six new custom enclosures with draw-out style breakers. Courtesy: National Breaker Services |

For the retrofit, National Breaker Services (NBS) was called in to replace all six breakers with draw-out style vacuum circuit breakers (Figure 4). NBS is a specialized provider operating from Middlebury, Connecticut, that engineers, designs, manufactures, retrofits, and services medium-voltage switchgear and circuit breakers.

What sets the company apart is its focus on ruggedness, utility-grade engineering, and adaptability to legacy systems. Its flagship offering, The Citadel, allows utilities to upgrade aging medium-voltage infrastructure without a full system replacement, maintaining or exceeding original equipment ratings while enabling modern maintenance practices.

Initially developed as fixed-mounted vacuum breaker elements to retrofit aging U.S. medium-voltage systems, The Citadel components are dimensioned to fit virtually any 5-kV or 15-kV legacy breaker chassis, with conservative ratings such as 15 kV with 95 kV basic impulse level (BIL), and current capacities of 1,600 A at 31.5 kA or 2,500 A at 40 kA.

|

|

5. The custom Citadel enclosures incorporate draw-out potential transformer assemblies, a modern feature that did not exist on the original 1903 breakers. Courtesy: National Breaker Services |

Over time, this platform evolved into a draw-out breaker design featuring remote racking options and roll-in replacement capabilities (Figure 5), meeting high performance levels including ratings up to 38 kV and current capacities of 5,000 A at 63 kA. NBS also offers indoor and outdoor switchgear, including dog houses, free standing units, walk-in common aisle substations, generator accessory cubicles, and modular engineering, procurement, and construction (EPC) line ups.

In this case, the Bulls Bridge project involved retrofitting the 1903 breakers with modern circuit breaker systems. Given the date of the original installation, the circuit breakers were not housed in the type of protective metal enclosure that became standard practice roughly 50 years later and remain in use today. Instead, they were open-air, a design that was common at the time but could pose potential safety risks for plant personnel.

After careful onsite measurements were gathered to ensure the new equipment could be engineered and designed to fit the very tight footprint, NBS removed the old breakers and installed six new custom enclosures with draw-out style breakers, in a process that took about two weeks. A draw-out breaker is designed to be inserted into and withdrawn from a switchgear cubicle or breaker compartment without having to disconnect the wiring or bus connections manually. This design provides flexibility, ease of maintenance, and improved safety compared to fixed-mounted breakers. The custom Citadel enclosures also incorporate draw-out potential transformer assemblies, a modern feature that did not exist on the original 1903 breakers.

|

The Push to Retrofit Aging U.S. Hydropower Dams U.S. government data shows there are more than 90,000 dams across the country, with about 2,100 of those—or less than 3%—used as hydroelectric facilities. More than 90% of those hydro dams are operated by private companies, public utilities, or state and local governments. The U.S. Energy Information Administration has said hydropower accounts for 6% to 7% of the nation’s power generation in any given year, depending on precipitation levels, with wetter years enabling more electricity output. Many of those hydro power stations, such as the Bulls Bridge facility in Connecticut, are in need of repair and upgrades to remain viable. Government data shows that perhaps 85% of U.S. dams are more than 50 years old, and while some are being torn down, those producing hydropower are being looked at as another source of clean energy at a time when demand for electricity is rising. As the Bulls Bridge project shows, existing dams can be retrofitted with new equipment, and even a facility that’s more than a century old can still support the nation’s energy supply. A project that includes advocates for hydropower, and those who want old dams removed from waterways, has formed to advance both goals. The “Uncommon Dialogue” project, an effort supported by Stanford University’s Steyer-Taylor Center for Energy Policy and Finance, and the Stanford Woods Institute for the Environment, is working on “helping leaders and other decision-makers address sustainability challenges by serving as a trusted source of scientific research and a neutral convener of diverse interests with the ability to co-develop practical solutions to pressing environmental concerns,” according to the group. Specific to dams and hydropower, the project since 2018 has worked to “find common ground on issues around hydropower and river restoration. Dialogue participants included NGOs [non-governmental organizations], hydropower companies, trade associations, government agencies, tribes, universities, and investors.” The group’s work was noted as critical for the inclusion of more than $3 billion in the federal Bipartisan Infrastructure Law. In a 2020 “Joint Statement of Collaboration,” the groups noted challenges, including: “To rapidly and substantially decarbonize the nation’s electricity system, the parties recognize the role that U.S. hydropower plays as an important renewable energy resource and for integrating variable solar and wind power into the U.S. electric grid.” Learn more about the work being done by the Stanford groups by visiting: —Darrell Proctor is a senior editor for POWER. |

The modernization of Bulls Bridge highlights the lasting value of historic infrastructure when combined with targeted upgrades, demonstrating that legacy systems can continue to deliver reliable power when supported by the right technical interventions. Bulls Bridge stands as a model for other aging power plants across the country (see sidebar), showing how Citadel breaker retrofitting can enhance and extend the operational life of critical hydro and fossil assets. The Citadel reduces costs and speeds turnaround time while improving safety for plant personnel.

—Jeff Elliott is a Torrance, California–based technical writer. He has researched and written about industrial technologies and issues for the past 20 years. For more information about the technologies featured in this article, call (475) 316-3471, email: jduggan@nationalbreaker.com, or visit nationalbreakerservices.com.