Gas

-

Gas

Industry Shift in Gas Line Cleaning Practice

The National Fire Protection Association has issued a new standard for gas line cleaning in response to the urgent recommendations prepared by the U.S. Chemical Safety Board.

-

Coal

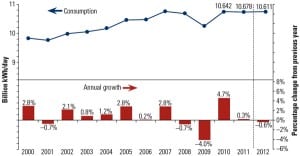

Abundant Clean Energy Fuels Brazil’s Growth

Brazil’s power industry has long been dominated by its vast hydro resources, which historically have accounted for over 80% of the country’s generation capacity. With engineering marvels like the massive Itaipú dam and the proposed Belo Monte project, the country is a leader in the development and use of hydroelectricity on a grand scale. But as the 2001 energy crisis proved, dependence on a single source leaves the country vulnerable to severe shortages. Thanks to government programs designed to take advantage of the country’s favorable climate, Brazil is committed to diversifying its energy mix while continuing to maintain a renewable energy focus.

-

Coal

Editors Select Top Five Stories of 2011

The POWER editorial staff’s picks for the most significant stories of 2011.

-

Coal

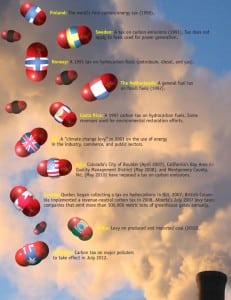

THE BIG PICTURE: Gas Taxes

After years of political wrangling, coal-rich Australia in November passed legislation that will require the nation’s top 500 polluters, starting in July 2012, to pay a tax at a fixed price of A$23 (US$23.50) per ton of carbon. The tax increases 2.5% annually until 2015, when an emissions trading program will begin. With the Kyoto […]

-

Coal

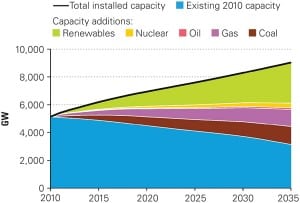

World Energy Outlook Forecasts Great Renewables Growth

Driven by policies to limit carbon emissions, as well as government subsidies, the share of worldwide nonhydro renewable power is set to grow from just 3% in 2009 to 15% in 2035, the International Energy Agency (IEA) forecasts in its recently released World Energy Outlook 2011. Under the same scenario—which assumes that carbon pricing, explicit […]

-

Coal

Australia Levies Landmark Carbon Tax

After more than a decade debating whether to pass a carbon-limiting law, Australia’s Senate in November voted in a landmark bill that will impose a price on carbon emissions. The country, which accounts for just 1.5% of global carbon emissions, but which is the world’s highest emitter per capita because 80% of its power comes […]

-

Gas

GE Uses Steel Mill Gases to Power Turbine

The world’s steel industry is power-hungry. Using energy both to supply heat and power for plant operations and as a raw material for the production of blast furnace coke, the sector uses a major fraction of the world’s total energy consumption. China’s steel and iron sectors have been mushrooming on the back of skyrocketing demand, […]

-

Coal

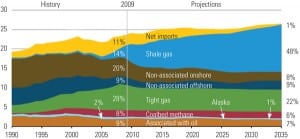

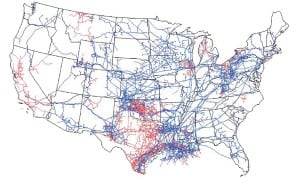

U.S. Confronts Pipeline Gaps While Europe Juggles Renewables and Debt

U.S. optimism has been restored by reports of abundant, reasonably priced natural gas to fuel most new generation; however, huge gaps in the fuel delivery system (thousands of miles of pipelines are needed) will soon challenge gas plant development. Meanwhile, the cloud of sovereign debt hangs over all major capital projects in Europe, where the UK moves ahead with new nuclear projects while many of its neighbors shut the door on nuclear and struggle to finance their commitment to renewables.

-

Coal

China’s 12th Five-Year Plan Pushes Power Industry in New Directions

The Five-Year Plan is the expression of the centralized planning goals for China’s economy. The 12th Five-Year Plan, approved by the Chinese Government on March 14, 2011, established many social and economic goals, including significant expansion of the country’s power generation industry in many new directions.

-

Gas

Gas Turbine Makers Gear to Flexibility Needs with New Models

Competition among gas turbine makers heated up this September as Alstom unveiled its upgraded GT24 gas turbine and corresponding 60 Hz KA24 combined cycle power plant, while Mitsubishi Heavy Industries (MHI) introduced the M701F5 gas turbine—a 50 Hz F-class gas turbine upgrade. An Upgraded GT24 Alstom’s upgraded product launches came on the heels of its […]

-

Gas

NorthWestern Energy Builds a Regulating Reserve Plant

Stable grid operation is challenging, especially when intermittent and unpredictable renewable generation is added to the generation mix. For NorthWestern Energy, the best solution was adding fast-acting gas-fired generation to its Montana electricity grid to meet required reliability standards while replacing expensive third-party contracts for ancillary services.

-

Coal

Restructuring the South African Power Industry

South Africa is at a critical turning point. An uncertain environment for private investment, escalating electricity prices, and a lack of available power threaten South Africa’s position as an attractive investment destination for many of the country’s most important industries. Power has been placed at the forefront of the government’s agenda, but South Africa needs a collaborative effort to meet the country’s energy demands and diversify its generation portfolio in order to drive economic growth.

-

Gas

Siemens Releases “Shaping Power” Option for Renewables Integration

The need for flexible power generation has increased drastically over the past few years, particularly when integrating renewables. Another driver is seasonal peaks in demand that have become more severe as global drought conditions have reduced hydropower production. One option for addressing this need is the Siemens Energy SGT6-5000F with Shaping Power. It offers the familiar gas turbine reoptimized for increased output and higher efficiency during hot weather and for improved operating flexibility at part-load conditions.

-

Gas

GE Develops FlexEfficiency 50 for Increased Operational Flexibility

The newest member of the 60% thermal efficiency combined cycle club is GE Energy’s FlexEfficiency 50. In an era when flexible grid operation is growing in importance, this 50 Hz, single-shaft combined cycle also holds its design point efficiency down to 87% load and features turndown to 40% of rated load.

-

Gas

Global Gas Glut: An Update

In our September article about the global profusion of natural gas, we based a portion of our discussion on the latest, vastly increased natural gas reserve estimates reported by the U.S. Energy Information Administration (EIA). Since our article was published, the EIA has adjusted its estimates downward. We want you to be aware of those lower recoverable reserve estimates. We also want you to know that the conclusions reached in that article do not change with the new estimates of natural gas reserves.

-

Gas

Blackout Leaves Southwest in the Dark

A large swath of Southern California, parts of Arizona, and Northern Baja Mexico was blacked out on Sept. 8—leaving seven million people in the dark—after an Arizona utility worker fixing faulty equipment near Yuma reportedly tripped the 500-kV North Gila–Imperial Valley transmission line, causing the outage. The blackout prompted two units at the San Onofre Nuclear Generating Station to go offline, stranded many people in elevators and trains, shut down airports, cut air conditioning on a day well above 90F, and caused damages of $97 million to $118 million, according to early estimates from the National University System’s Institute for Policy Research.

-

Gas

Nordic Nations Provide Clean Energy Leadership

In the past few years, nuclear concerns, rising oil prices, and a growing understanding of our environmental impact has given energy issues a higher profile worldwide. In this report on the Continental Nordic countries, we look at the efforts being made in much of the Nordic region to secure a sustainable energy supply for the future and at the extent to which the innovative solutions of these countries can be exported around the globe.

-

Gas

New Peaking Plant to Balance California’s Renewables

As utilities in California are scrambling to meet the state’s 33% renewable mandate by 2020, a 49.6-MW peaking plant in Modesto, Calif., built by Finnish firm Wärtsilä for the Modesto Irrigation District, has been commissioned to provide flexible, fast-start peaking generation to balance the state’s increase in intermittent renewable generation (Figure 4). 4. Flexible peaking. […]

-

Gas

Kuwait Starts First Turbines of 2,000-MW Gas Plant

Kuwait put online the first 1,400 MW of its massive 2,000-MW combined cycle gas turbine Sabiya facility in June to mitigate looming power shortages it faces each summer. The plant—Kuwait’s largest power plant and one of the largest in the Gulf region—is now operating six GE 9FA gas turbines; the remaining 600 MW are expected […]

-

Coal

THE BIG PICTURE: Lights Out

Heat waves, droughts, and other weather and climate phenomena; economic woes; aging or inadequate infrastructure; fuel shortages. These are some of the most obvious causes that have led to record peaks in power demand or sudden drops in available capacity. The results have been sometimes debilitating load-shedding, brownouts, and blackouts around the globe this summer (and, in some cases, for much longer). Here’s an overview of which countries are affected by which difficulties. For a more detailed look at the extent of shortages and what’s causing them, visit Web Exclusives at https://www.powermag.com

-

Coal

Explosion Devastates Major Cypriot Power Plant

A brush fire that spread and detonated explosives stored at the Evangelos Florakis naval base in Mari on the southern coast of Cyprus on July 11 killed 13 people, injured 62 others, and severely damaged the Vassilikos Power Station—an oil- and gas-fired plant that supplied almost 60% of the island nation’s power. Cyprus, which was once considered an “economic miracle,” has been battling crippling power shortages that have beleaguered its financial and tourism sectors since the blast and left it on the verge of economic collapse.

-

Gas

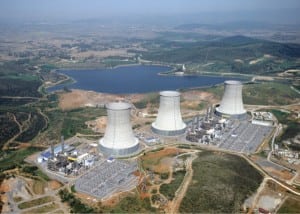

Top Plant: Adapazari Power Plant, Adapazari, Sakarya Province, Turkey

In 2010, the 2,310-MW Adapazari Power Plant achieved 99.8% availability, which is nearly 7% higher than the industry average and a global record in F-class gas turbine technology. The new turbine upgrade is helping ENKA Power bolster Turkey’s evolving economy by improving its energy sector’s efficiency and productivity.

-

Gas

Top Plant: Arvah B. Hopkins Generating Station, Unit 2, Tallahassee, Florida

Known for its progressive, pro-sustainability policies, the City of Tallahassee recently repowered a 30-year-old conventional steam plant unit, turning it into a new 300-MW facility. The utility redesigned the Arvah B. Hopkins Generating Station, Unit 2 as a 1 × 1 combined cycle plant in order to improve efficiency, switched the primary fuel from oil to natural gas, and thereby reduced fuel costs and emissions. The plant’s flexible design even will enable expansion to a 2 × 1 configuration when additional capacity is needed in the future.

-

Gas

Top Plant: Astoria II Combined Cycle Plant, Queens, New York

Managing construction of the 550-MW Astoria II Combined Cycle Plant in the midst of Queens, a densely packed New York City borough, required extensive off-site modular construction and a high level of logistical organization. Now the new Astoria II plant is operating successfully in conjunction with the Astoria Energy I plant as the largest natural gas–fired power plant in the Big Apple.

-

Gas

Top Plant: Emirates Aluminum Smelter Complex (EMAL), Al-Taweelah, Abu Dhabi, United Arab Emirates

The new 2,100-MW Phase 1 EMAL combined cycle power plant provides dedicated power with a high level of reliability to the Emirates Aluminum Smelter Complex, which is designed to be the world’s largest aluminum smelter upon completion. Located on the Persian Gulf, the gas-fired combined cycle plant uses seawater cooling towers to eliminate thermal stress on local marine life.

-

Gas

Top Plant: Irsching 4 Combined Cycle Power Plant, Irsching, Bavaria, Germany

The Irsching 4 Combined Cycle Power Plant has set a new world record in power plant efficiency with its new SGT5-8000H gas turbine. With an output of more than 578 MW and efficiency of 60.75% (net) achieved at a world record test run in May 2011, the plant demonstrates that climate protection, low-cost power generation, and flexible operation using fossil fuels can be attained simultaneously through technical advances. Due to its high efficiency, the gas-fired plant uses significantly less fuel and produces lower carbon dioxide emissions than traditional combined cycle plants.

-

Gas

Top Plant: Montoir-de-Bretagne Combined Cycle Plant, Montoir-de-Bretagne, France

The 435-MW Montoir-de-Bretagne gas-fired power plant is ramping up Gallic generation in the Loire-Atlantique region of western France. The plant’s innovative natural gas combined cycle technology offers high efficiency and low emissions.

-

Gas

Global Gas Glut

Marcellus Shale gas has increased recoverable natural gas reserves in the U.S. by about a third over estimates prepared a few years ago. Europe is also exploring shale gas as an alternative to problematic Russian gas supplies and low proven natural gas reserves. POWER contributors in the U.S. and UK examine the comparative economic value, public acceptance, and political implications of these massive shale gas reserves.

-

Coal

Best Practices for Natural Gas Line Cleaning

As barriers to new coal-fired generation expand and enthusiasm for nuclear plants wanes, the commissioning of natural gas–fired plants promises to increase. However, gas plants pose hazards, too. An explosion last year that was caused by unsafe use of natural gas to blow residue from a gas pipeline during commissioning of a gas-fired power plant has focused regulator and industry attention on finding safer alternatives for this task. Fluor shares its gas pipeline cleaning best practices.

-

Gas

Who Pays for Firming Up Variable Energy Resources?

The major economic hurdle for renewable power generation technologies continues to be substantial installation costs. But another cost is associated with continuous load-balancing, made possible by backstopping that variable generation with dispatchable generators that typically consume expensive fossil fuels. Bottom line: Who pays for the capacity firming or backstopping resources?