Among the various types of valves on the market, ball valves are critical in high-pressure systems, enabling precise fluid control in industries like power generation, chemical processing, and oil and gas. Although they’re designed to handle extreme operational demands, the intense conditions of high-pressure environments make regular maintenance or replacement essential to minimize downtime, extend equipment life, and uphold safety standards.

This guide outlines maintenance best practices for ball valves in high-pressure applications, so you’ll have the practical insights needed to maximize system performance and reliability.

The Role of Design in Maintenance Efficiency

A ball valve’s design directly influences its maintenance needs. Specialized design features, such as innovative sealing technology, can reduce the frequency of servicing by providing longer-lasting protection against leaks and wear. Additionally, certain materials like polytetrafluoroethylene (PTFE) and Viton can enhance durability, especially in high-pressure environments where resistance to chemicals and temperature extremes is essential.

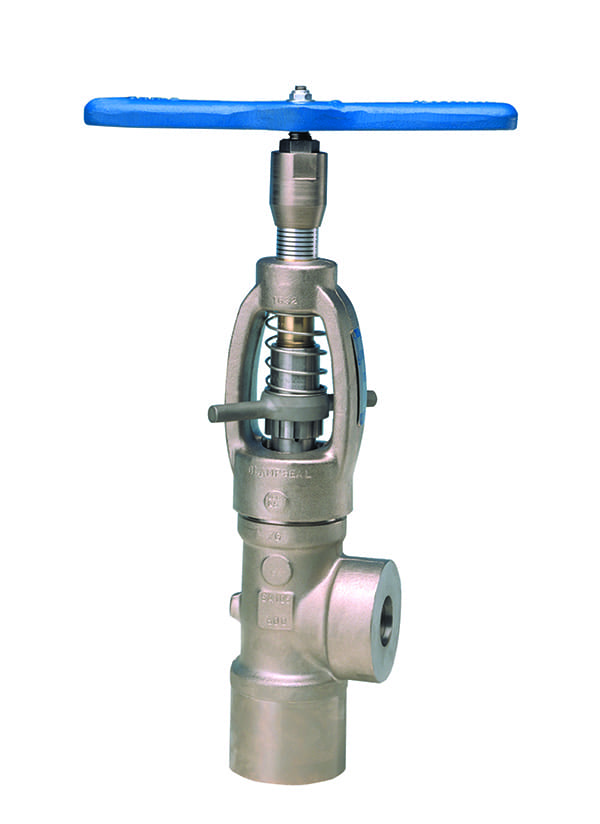

However, not all ball valves are designed for repair. In many cases, it’s more practical to replace a worn valve rather than attempt repairs, especially for non-serviceable models. For valves designed with reparability in mind, maintenance is straightforward and allows for the replacement of individual components like seals, seats, and any other parts within the valve that are prone to wear. This style of ball valve is typically referred to as a 3-piece ball valve (Figure 1).

With actuated ball valves, the valve is often a fraction of the cost of the full assembly, and typically the first component to fail. It can be replaced fairly economically, and one actuator will likely last the life of a number of ball valves.

Four Best Maintenance Practices for Ball Valves

In those cases where ball valve maintenance is appropriate, follow four critical steps to optimize their performance and extend their lifespan in high-pressure environments.

Routine Inspections. Regularly examine ball valves to uncover early signs of wear, such as leaks, stem seal degradation, or operational resistance. Focus on key areas such as:

- Stem Seals. Check for cracks, hardening, or misalignment.

- Seating Surfaces. Ensure that seats remain intact to maintain an effective seal.

- Bolts and Joints. Verify proper tightness and alignment.

Cleanliness and Lubrication. Dirt and debris accumulation can compromise valve performance and lead to failures. Maintain cleanliness by flushing the system as needed and cleaning valve exteriors. Additional best practices include:

- Applying suitable thread lubricants to minimize friction and protect against corrosion.

- Following the manufacturer’s recommendations for compatibility with valve materials.

Pressure Testing. Conduct regular pressure checks to ensure system safety. Test procedures should include:

- Verifying the valve’s ability to maintain a pressure seal within design limits.

- Monitoring for leaks under operational and standby conditions. Exceeding pressure differential limits can damage valve components, so this step is crucial.

Component Replacement. Timely replacement of worn components, such as seals, seats, and balls, is vital. However, in many high-pressure applications, the best approach is to keep spare valves on hand. Replace leaking valves with new or pre-maintained units to minimize downtime and simplify logistics.

Three Ball Valve Maintenance Challenges (and How to Solve Them)

Maintenance challenges are inevitable in demanding environments. Here’s how to address three common issues.

Seal Wear from High Pressure. Solution: Regular inspections combined with the use of pressure-rated valves designed for high-stress conditions can mitigate seal wear.

Corrosion in Aggressive Environments. Solution: Opt for valves made from corrosion-resistant materials like stainless steel or alloy. These materials withstand chemically harsh conditions and prolong service life.

Blockages from Debris. Solution: Incorporate filtration systems to trap debris before it enters the valve. Routinely clean the valve interiors to prevent obstructions.

Additional Ball Valve Maintenance Tips

The inspection frequency for high-pressure ball valves depends on usage and operating conditions. In most cases, quarterly inspections are sufficient for early detection of issues.

Use lubricants compatible with your valve materials. PTFE-based lubricants are often recommended for their durability and friction-reducing properties.

Replace seals or seats at the first signs of wear, such as leaks or reduced sealing performance. Refer to the manufacturer’s guidelines for specific recommendations.

Always verify the valve’s pressure rating against your system’s operating parameters. Consult the manufacturer’s specifications to avoid overloading the valve.

Maintaining Reliability in High-Pressure Systems

Ball valve maintenance helps ensure the safety, efficiency, and reliability of high-pressure systems. Regular inspections, cleaning, and pressure testing can help extend the life of your valves and reduce the risk of unexpected failures. However, in many high-pressure applications, replacing a worn valve may be more practical and cost-effective than attempting repairs.

—Seth Sherman is a technical sales representative with Gemini Valve.