Power plant operators are always looking for ways to boost performance. A combustion optimizer designed to improve efficiency and lower emissions could help. It supports more flexible operation of boilers by manipulating fuel and air control settings via closed-loop biases. This improves the combustion characteristics in the boiler, making it possible to operate in the optimum zone while avoiding high CO emissions.

Staying in the coal power business isn’t easy these days. Continual stiffening of environmental regulations has plant economics in a vise. The only option for those facilities that can stay open is to find ways to increase efficiency. This includes the introduction of technology to lower costs, minimize emissions, and improve profitability.

But operational challenges are often raised by making major changes that were not part of the original design. Different fuels, several layers of emission control equipment, load variance to enable renewables to operate on the grid, and adding the capability to ramp more rapidly are examples of some of the approaches taken by plants to improve the cost equation. However, these changes are likely to place severe strain on operations and maintenance (O&M).

Unprofitable Comfort Zone

It becomes essential, therefore, to optimize processes in order to reduce stack emissions, raise the efficiency of coal-fired boilers, minimize O&M costs, and improve performance and unit availability. The key to achieving this in the current market is to run steam power plants at the most profitable operating point.

That is easier said than done. It is difficult for operations staff to monitor and continually adjust fuel and air parameters in an attempt to respond to changing unit load, fuel characteristics, and boiler dynamics. It isn’t cost-efficient to assign someone full time to micromanage combustion processes. The usual practice is to find the “comfort zone” of each unit.

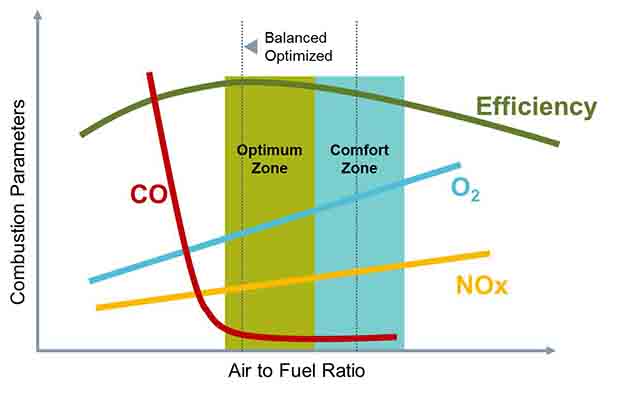

The comfort zone is an operating range that requires few dynamic adjustments. Operating in this zone helps plants to lessen the potential for incomplete combustion. However, it has a detrimental long-term effect. Over time, operation within the comfort zone lowers overall efficiency, raises emissions, and curtails profitability.

The reason: this comfort zone is typically at a point where the risk of high carbon monoxide (CO) emissions is minimized. By maintaining a safe margin from a CO emissions spike, though, plants are forced to operate with higher O2 and NOx levels (Figure 1). This approach may have worked five years ago, but more rigorous environmental demands make it a dangerous game now. Straying out of compliance for even short periods can eliminate what little profitability may exist.

|

| 1. The comfort zone used by many plants hurts profitability. An optimum zone of operation exists, but it requires much tighter control of combustion processes. Courtesy: Siemens |

Inside the comfort zone and closer to the point where CO emissions spike is the optimum zone of operations. Manual processes are not capable of remaining in this range consistently over a long period of time. The only way to achieve this objective is through optimization of the boiler combustion conditions via automation.

Automated Combustion Optimization

Siemens Omnivise Combustion Optimizer has been designed to improve efficiency and lower emissions. At the same time, it supports more flexible operation of boilers by manipulating fuel and air control settings via closed-loop biases. This improves the combustion characteristics in the boiler, making it possible to operate in the optimum zone without drifting into the zone of high CO emissions.

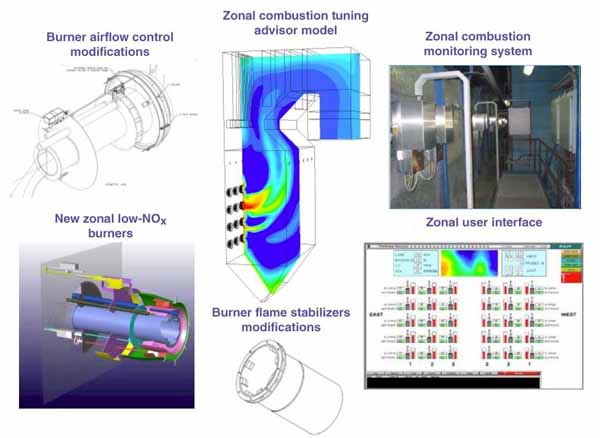

Combustion Optimizer software requires no modifications to mechanical equipment. It harnesses process data automatically to determine optimal biases for manipulated variables. It integrates with data sources such as the Emerson Ovation distributed control system (DCS), Alstom’s Low-NOx Concentric Firing Level II system, Black & Veatch’s OPM performance monitoring software to measure heat rate, and the ZoloBOSS in-furnace measurement system from John Zink. The laser-based, tunable diode laser absorption spectroscopy system provides grid mapping of temperature, oxygen (O2), CO, and moisture (H2O) concentrations in the flue gas at the furnace exit.

The Combustion Optimizer and ZoloBOSS system were implemented at Basin Electric Power Cooperative’s Antelope Valley Station (AVS). AVS is located near Beulah, North Dakota. The plant consists of two 1980s-vintage, 470-MW, tangentially-fired units designed for North Dakota lignite coal. The boilers are rated for 3,136,000 lb/hr at 2,640 psi with a reheat and superheat temperature of 1,005F. Each unit is equipped with low-NOx burners and separated over-fire air (SOFA) for NOx control, and dry flue gas desulfurization and fabric filters for SO2 and particulate control.

North Dakota lignite is soft with relatively low sulfur and ash content but a high moisture content. It has a heating value of 6,600 Btu/lb. Coal mill pulverizers process and deliver fuel to the burners. Air adjustments are made using auxiliary air dampers, as well as close-coupled overfired air (CCOFA) and SOFA.

Basin Electric introduced closed-loop optimizers at its coal plants to reduce the need for manual adjustments to control systems and provide consistency in unit operation. The Combustion Optimizer uses artificial intelligence and control techniques to determine biases for various fuel and air settings, which are applied to the plant’s DCS in a closed-loop system configuration (Figure 2). The in-furnace, John Zink laser-based combustion monitoring system provides additional data to continuously address combustion characteristics at the furnace exit and balance combustion profiles. As a result, long-term operational trends at AVS showed plant performance enhancements, heat rate improvements, and NOx reductions on both units at the station.

|

|

2. Siemens’ Omnivise Combustion Optimizer can be integrated with non-Siemens distributed control systems, such as the Emerson Ovation system used in the control room at the Antelope Valley Station (AVS), shown here. Courtesy: Basin Electric Power Cooperative |

Living in the Zone

For many decades, these units operated at baseload, but the opening of many wind farms in the region changed marketplace dynamics. As a result, daily load swings have become the norm. The software upgrades implemented at AVS were designed based on parametric testing and data analysis. They add a greater degree of control over the combustion process, and ultimately optimize operations by being able to run the boilers in the optimum zone without risk of emissions non-compliance.

Bidirectional data communications between the Combustion Optimizer server and plant DCS is facilitated by data communication modules supporting Modbus TCP/IP protocol. Thus, the DCS and the Optimizer can share process data and determine the optimum biases for air flows and feeder rates. A client computer connected to the Optimizer server provides operator control. An OPC connection feeds ZoloBOSS laser measurement system data to the Combustion Optimizer.

Based on this data, the system calculates the difference between the setpoint from the existing DCS and the optimum setpoint. Adding this bias to the DCS setpoint enables the system to operate at the optimum setpoint. The operator has the option of shifting back to the DCS setpoint as desired. The Combustion Optimizer continuously manipulates variables and transmits biases to the DCS for closed-loop control.

Average values for temperature, O2, CO, and H2O are determined every few seconds by a laser beam transmitted by a pitching head that travels through the boiler (Figure 3). The Combustion Optimizer uses this data to improve the combustion profile.

|

|

3. Zolo laser-based combustion monitoring equipment is shown here mounted on a boiler wall. The system provides measurements of temperature, H2O, CO, and O2, so operators can maintain close control of in-furnace conditions. Courtesy: Basin Electric Power Cooperative |

Various techniques are employed by the Combustion Optimizer to ensure accuracy. Machine learning, for example, is harnessed to develop boiler models based on historical plant operating data. Variability in air flow, feeder rates, unit load, and fuel information are considered by these models in an effort to attain target values for NOx, heat rate, CO, and other parameters.

Another technique employed is sensitivity analysis. This is used to identify additional variables that may have the greatest impact on target values. Examples of potential variables include equipment wear and tear, fuel variability, and slagging. Additionally, online learning is used to assist the various models in adapting to changing conditions.

Optimization Goals and Results

The primary objectives for the implementation of combustion optimization at AVS were to reduce NOx and improve heat rate. To achieve this, the Combustion Optimizer utilizes the complete spectrum of data, such as:

■ Unit load, fuel information, and ambient conditions.

■ Flue gas temperatures and differential pressures.

■ Excess oxygen and windbox differential pressures.

■ Nitrous oxide and carbon monoxide.

■ Opacity, boiler efficiency, and heat rate.

■ Mill feeder speeds, motor amps, differential pressures, outlet temperatures, primary air, and secondary air.

■ Superheat and reheat steam temperatures, and attemperation sprays.

■ Laser measurements including flue gas O2, temperature, CO, and H2O.

■ Permissive signals (binaries).

■ Damper parameters, auxiliary air, SOFA, and CCOFA.

■ Burner tilts and SOFA tilts.

Operator interaction with the Combustion Optimizer is done via the DCS. Data communication failure alarms, if any, are displayed on the human-machine interface.

The Combustion Optimizer was commissioned on both units in March of 2017. It has operated almost continuously since then, except for short periods of routine plant maintenance and repair.

An in-depth data analysis was done to evaluate long-term results. A baseline data set with the Optimizer off was first gathered at AVS from October 1, 2016, to March 15, 2017, which was prior to the system being installed. The Optimizer-on period evaluated was from March 16, 2017, to July 31, 2018, using one-hour-average values to minimize undue variations in trends. Lower-load data was sparse and therefore it was all filtered out for the purposes of simplifying the evaluation. Similarly, data outliers not representative of normal operation were excluded.

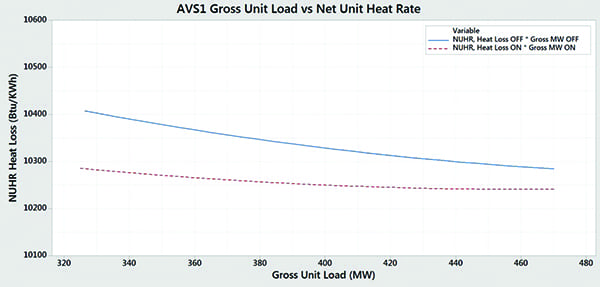

Data analysis highlighted improved consistency in unit operation from one shift to the next and a general flattening of regression fit curves when the Combustion Optimizer was in service. Overall, this amounted to a 0.44% improvement in AVS Unit 1’s net heat rate at full load and gains of up to 1.2% at other loads (Figure 4). NOx levels in Unit 1 at AVS showed a 19.7% improvement at full load. Superheat steam temperature was also found to be higher at full load by 16F, and superheat and reheat steam temperatures remained closer to the desired unit setpoint. This contributed significantly to heat rate improvements.

|

|

4. AVS Unit 1 gross unit load versus net unit heat rate showed improvements of up to 1.2% due to combustion optimization. Courtesy: Siemens |

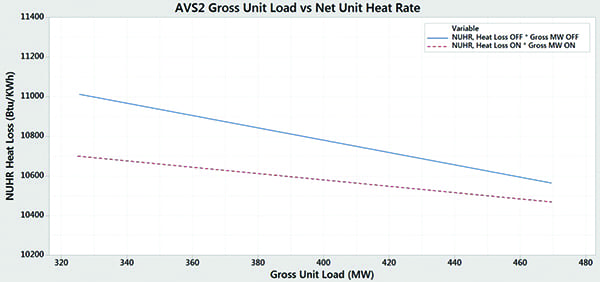

Unit 2 showed similar improvements. This included a gain of 0.91% in net heat rate at full load and up to 2.85% at other loads (Figure 5). Measured NOx levels highlighted a 19.6% reduction at full load. In addition, testing showed a 5F boost in superheat steam temperature, and a 14F spike in reheat steam temperature at full load.

|

|

5. AVS Unit 2 gross unit load versus net unit heat rate showed improvements of up to 2.85% due to combustion optimization. Courtesy: Siemens |

After 18 months of testing, Basin Electric’s AVS facility found positive gains from the deployment of the Siemens Omnivise Combustion Optimizer. While realizing heat rate and NOx gains highlighted above, fly ash loss-on-ignition values were maintained below 2%. ■

—Neel Parikh is a principal engineer with Siemens Energy, and Kyle Keidel is a performance engineer with Basin Electric Power Cooperative.