Mitsubishi Power is developing a 40-MW class gas turbine that can directly combust 100% ammonia under an initiative that responds to heightened global decarbonization ambitions, as well as Japan’s recent roadmap for ammonia fuel.

The Yokohama–headquartered power equipment firm, a subsidiary of Mitsubishi Heavy Industries (MHI), on March 1 said it is targeting commercialization of the novel ammonia-capable gas turbine, which will be derived from its H-25 series, “in or around” 2025.

“When achieved, it will mark the world’s first commercialized gas turbine to make exclusive use of ammonia as fuel in a system of this scale,” the company said. The gas turbine will “aid in the promotion of decarbonization of small to medium-scale power stations for industrial applications, [and] on remote islands,” it said.

Direct Gas Turbine Combustion of Ammonia

The development is a notable new direction for Mitsubishi Power. Under its “Change in Power” campaign, the company is spearheading decarbonization technology development specifically geared to its flagship line of advanced gas turbines, and so far, it has made striking advances.

Responding to Japan’s Basic Hydrogen Strategy, the company in 2018 set out to develop a large gas turbine that can combust 100% hydrogen. While Mitsubishi Power continues work on a pilot project to convert one of three units—a 440-MW M701F gas turbine—at Vattenfall’s 1.3-GW Magnum combined cycle plant in the Netherlands to renewable hydrogen by 2023, its Lake Mary, Florida–based Mitsubishi Power Americas arm in March 2020 secured its first contract for two hydrogen-capable M501JAC power trains to replace 1986-completed coal-fired units at the 1,800-MW Intermountain Power Project (IPP) in Utah.

In September 2020, it launched two standard hydrogen integration packages, “Hydaptive,” which is focused on power plant site integration, spanning the electrolyzers to the gas turbines, and “Hystore,” which develops hydrogen’s storage attributes. And that same month, it secured more contracts stemming from its hydrogen capability from developers for proposed gas power plants in Virginia, Ohio, and New York, as well as a hydrogen integration contract with Entergy Corp. In December, Canadian power producer Capital Power also ordered two M501JAC turbines to repower its Genesee Units 1 and 2 in Alberta from coal to natural gas.

Mitsubishi Power has said that because its M501JAC gas turbine model integrates a combustor technology to address flashback (backfire), combustion pressure fluctuation, and nitrogen oxide (NOx) emissions, the J-series model is already capable of combusting a mix of natural gas and up to 30% hydrogen. To get to a 100% hydrogen capability, technology developers are now exploring combustor technology that enables efficient mixing of hydrogen and air via an upgraded fuel delivery nozzle design. Mitsubishi Power Americas CEO Paul Browning in February told POWER the company is targeting development of 100% hydrogen combustion technology by 2025.

However, in tandem, Mitsubishi Power (and MHI) have also been studying gas turbine systems using ammonia as an energy carrier. Since 2017, as part of the Japanese Cabinet’s Strategic Innovative Promotion Program, and Japan’s New Energy and Industrial Technology Development Organization (NEDO), the company has focused efforts on developing a system that thermally cracks—using waste heat—ammonia (NH3) into hydrogen and nitrogen, and then combusts that hydrogen in a gas turbine.

Company documents suggest the approach may be better suited for smaller gas turbines, owing to specific characteristics associated with ammonia combustion. For example, because ammonia has a low combustion speed, it requires a much larger combustor. And because ammonia contains nitrogen, any system using it as a fuel will need to tackle the “fuel NOx” it generates, it said. Mitsubishi Power has explored lowering the NOx via two-stage combustion, but it said larger gas turbines posed “many technical problems, such as upsizing and complication of the combustor.”

Development of the 40-MW ammonia-capable gas turbine announced this week, however, suggests Mitsubishi Power is rethinking the multistage ammonia-cracking approach to explore “a method for directly combusting ammonia.”

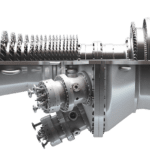

To address NOx production, which is prompted by oxidation of ammonia’s nitrogen component through its combustion, the company’s commercialized gas turbine system will combine selective catalytic reduction (SCR) with “a newly developed combustor that reduces NOx emissions,” it said. That system will then be installed in the company’s H-25 series gas turbines (Figure 1), a model which Mitsubishi Power has commercially sold to utilities and industrial users since 1988.

Ammonia Garnering Interest as a Fuel

As Mitsubishi Power noted, commercialization of an ammonia-capable gas turbine will “expand” its lineup of “carbon-free power generation systems.” It suggests a market for the product is emerging: “Expectations are held that early introduction of ammonia-based power generation equipment at power companies and independent power providers (IPPs) will promote ammonia’s future use as a carbon-free fuel,” it said.

The effort rides a recent resurgence of interest in ammonia’s suitability as a decarbonized fuel because its combustion produces no carbon dioxide, sulfur dioxide, or soot. Interest in ammonia is also heightened owing to its potential as an efficient energy carrier because it has a high hydrogen density (17.8 weight %). As the second most commonly produced chemical (after sulfuric acid) globally, ammonia is today mainly utilized as an agricultural fertilizer, and in food production, industrial materials, refrigerants, and additives—which means it has a well-established global distribution network. It is also generally considered stable for long-term storage and transportation.

But while efforts to use ammonia in the energy sector have been explored for several decades, energy harvesting from ammonia has been limited by various challenges. “One concern is that ammonia is toxic and flammable,” MHI noted. “And while there are existing standards and procedures, the required handling skills are not commonly known outside of sectors that already use ammonia and its derivatives.”

Another significant challenge is that “the production of green hydrogen through electrolysis powered by renewable electricity is not yet of a scale to be viable compared with conventional fossil feedstock and therefore so is the production of green ammonia,” the company said. However, while most ammonia today is produced from natural gas, several initiatives are underway to produce “renewable” ammonia by converting green hydrogen to ammonia.

MHI has been notably active on this front. In November, the company announced an investment in the Hydrogen Utility (H2U), an Australian developer of green hydrogen and ammonia projects, saying it will back a front-end engineering and design study for H2U’s Eyre Peninsula Gateway project in South Australia, which is slated to begin commercial production of green hydrogen and ammonia in 2023.

In November, MHI also completed a capital investment in Monolith Materials, a U.S. firm that could enable production of hydrogen and carbon black from methane. Monolith Materials, which already operates a commercial-scale carbon black production facility, Olive Creek 1, in Nebraska, plans to begin operating a second facility to produce “turquoise” hydrogen through its pyrolysis technology that uses renewable energy as a heat source. Meanwhile, earlier this February, MHI announced another methane pyrolysis investment in the Series A financing round for the start-up C-Zero.

Japan Ramps up Ammonia Power Generation

How “green ammonia” will be used is also of growing interest. Several countries have outlined ambitions to integrate ammonia in their future energy system, including as a fuel for fuel cells and internal combustion engines. Japan, which prominently leads these efforts, envisions a substantial role for ammonia power generation. An updated overview of its “green growth” strategy issued by Japan’s Ministry for Economy, Trade, and Industry (METI) this February, for example, suggests “full ammonia power generation” could be demonstrated by 2045. An associated roadmap (Figure 2) also lays out a vast ammonia supply chain expansion that will render the country into a regional exporter of ammonia fuel.

Ammonia-coal co-firing has so far already been demonstrated in Japan, first by Chugoku Electric in July 2017 at its 156-MW Mizushima Thermal Power Station Unit 2 with a fuel mix composed of 0.6% to 0.8% ammonia, and then by IHI Corp. in March 2018 at a “large-capacity combustion facility” in Aioi City, with a fuel mix composed of 20% ammonia. Another Japanese firm, JERA, in November announced it plans to shutter its entire 2.2 GW supercritical coal power generation fleet in Japan by 2030, and then gradually increase the ratio of mixed combustion of fossil fuels to ammonia and hydrogen at ultrasupercritical plants.

But though turbine-based ammonia-fuel power generation was introduced in the mid-1960s—and it saw a relative resurgence in the 1990s—it has not been practically adopted as a single fuel for turbines. Japan’s breakthrough arrived in 2016, when a research team led by Hideaki Kobayashi, professor at the Institute of Fluid Science at Tohoku University in Sendai, demonstrated ammonia-air combustion using a 50-kW micro-gas turbine system at the National Institute of Advanced Industrial Science and Technology. The team’s combustor adopted gaseous NH3 fuel and diffusion combustion to enhance flame stability.

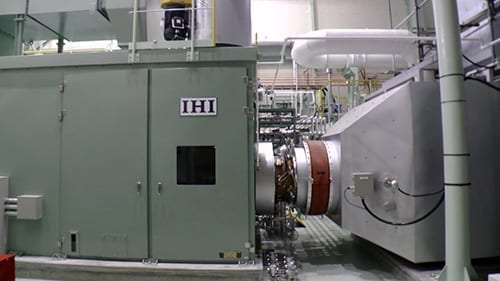

Meanwhile, though Mitsubishi Power’s efforts to commercialize a 100% ammonia-capable gas turbine is notable, the company already has competition. IHI Corp. in October 2020 began co-firing tests on a 2-MW class gas turbine at its Yokohama Works facility (Figure 3), utilizing “blue” ammonia—ammonia produced from natural gas—as fuel.

The project aims to raise the ammonia co-firing ratio to more than 50% on a calorific value basis. “The process for producing ammonia from natural gas entails capturing carbon dioxide emissions using them for enhanced oil recovery and for carbon capture and utilization,” IHI said. The company noted it is conducting the gas turbine tests under a program spearheaded by Japan’s Institute of Energy Economics and the Saudi Aramco Oil Co. that aims to demonstrate the feasibility of the blue ammonia supply chain.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).