Hydrokinetic energy — which generates power by using underwater turbines that harness moving water — is on the rise in the U.S. In January, the first U.S.-licensed, commercial, grid-connected hydrokinetic project installed the first of two 100-kW nameplate-rated turbines downriver from an existing run-of-river hydroelectric plant on the Mississippi River.

These days many renewable energy proponents are upbeat about downstream currents and their huge energy potential. Because hydrokinetic power generation relies simply on the extraction of energy from the natural velocity of water, these power systems can be placed into sources of flowing water with minimal infrastructure or environmental impacts.

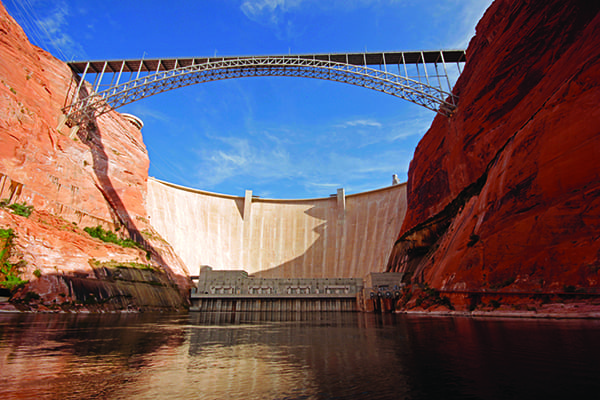

Hydrokinetic energy is a new application of the concept of using water to create electricity — in this case by harnessing the natural flow or current of water. Traditional hydropower, in contrast, relies upon dams, diversionary methods, or other manmade impounding structures behind which potential energy in the water is stored.

Conventional hydropower today accounts for roughly 8% of U.S. electric output and well over 80% of U.S. renewable energy capacity (with wind, solar, geothermal, and biomass contributing the remaining 20%). As of early 2009, the only source of commercial hydrokinetic power in the U.S. is the new 200-kW nameplate-rated hydrokinetic project (expected to deliver a peak 70 kW) located in Hastings, Minn. (Figure 1).

1. Go with the flow. The Hastings hydrokinetic turbine is located behind the turbine of the existing conventional hydropower plant and uses a one-to-one turbine ratio to generate additional power from the energy remaining in the water current exiting the dam and flowing downstream. Also seen is a support barge used during installation. Courtesy: Hydro Green Energy

How Hydrokinetic Power Works

In February, POWER interviewed Wayne Krouse, the chairman and CEO of Houston-based Hydro Green Energy, about his company’s new technology, its use at the new power station near Hastings, and overall trends related to hydrokinetic energy.

"Hydro Green Energy’s hydrokinetic technology operates in river, tidal, and, potentially, ocean currents," he said. "In our Hydro+ systems, we locate the hydrokinetic turbine behind an existing conventional facility’s turbine on a one-to-one ratio to generate additional power from the energy remaining in the water current exiting the dam and flowing downstream. Placing the hydrokinetic turbines downstream from an existing hydropower plant is simply an application point for our patented technology. One way to think of this type of project is that it is the waterpower version of cogeneration: We are generating clean energy twice from the same water resource at a specific location."

Hydro Green Energy calls this type of project a Hydro+ project and has filed a number of patents on the approach; the company was the first entity to develop this method.

In an open-river setting, hydrokinetic power projects will have a capacity factor (CF) of over 99% because power will be generated by using a constant, unidirectional water current, explained Krouse. He pointed out that this is baseload power. In a tidal setting, the CF would be in the neighborhood of 30%.

At a hydro site where the existing hydropower facility operates in run-of-river mode, the CF is directly tied to the CF of the conventional hydropower plant. At a non-run-of-river hydropower plant, the CF of the hydrokinetic units may be higher than the CF of the conventional plant due to minimum flow requirements or other parameters.

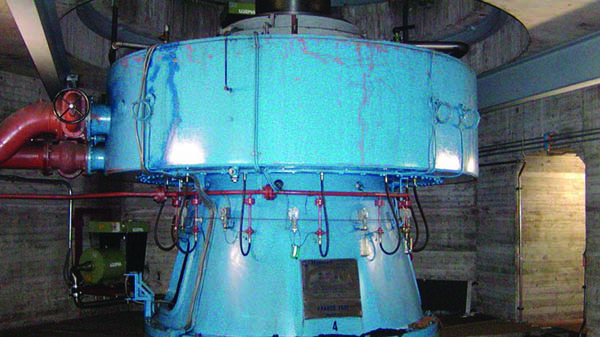

The rotational speed of the company’s turbine is 21 rpm — the lowest in the hydrokinetic industry (Figure 2). The turbine blades can be stopped from spinning in approximately 8 seconds. In addition, the turbine can be pulled out of the water and placed in the service mode in under 2 minutes, leaving very little infrastructure below the waterline.

2. Hard-working water. After the second turbine is installed this summer, the Hastings hydrokinetic power station is projected to produce a maximum of 1,454 MWh of electricity annually. Courtesy: Hydro Green Energy

"The barges from which the hydrokinetic turbines are deployed (and the turbines themselves) are able to withstand wide fluctuations in water levels, substantial velocity increases, and direct impacts from large and fast-moving objects," Krouse emphasized. "The only flow parameter that would decrease power output would be a decrease in flow through the units. During extraordinary high water or flood events, the hydrokinetic arrays, which are the multi-units attached to one of the barges, could be removed from the river if necessary."

Krouse also discussed the long-term production potential of the two hydrokinetic turbines at the Hastings site.

"Power is proportional to the cube of velocity," he said. "Velocities downstream from the Hastings conventional hydropower plant vary from 3.5 m/s (11.5 ft/s) (nearest to the existing hydro plant) to 1 m/s (approximately 100 feet downstream). The units are designed for at least a 20-year lifespan. At the design point, the coefficient of performance (COP or water-to-wire efficiency) for the Hastings hydrokinetic units is 0.62, the highest in the hydrokinetic power industry at this point in time."

Using an 83% CF at nameplate capacity (100 kW per unit at 3.5 m/s), the Hastings hydrokinetic power station will produce a maximum of 1,454 MWh annually, Krouse said. Over a 20-year period, the units will achieve maximum incremental power output of 29,080 MWh. At 2.25 m/s, the hydrokinetic units together would produce approximately 508 MWh annually and 10,160 MWh over 20 years.

Hydro Green Energy is responsible for all operations and maintenance of the Hastings hydrokinetic units. These duties will be handled by the company’s engineering and project management staff, as well as local contractors.

Advantages of the Project’s Location

Unlike many new renewable energy facilities in the U.S., the Hastings hydrokinetic power station did not face any grid interconnectivity or transmission line access challenges.

"Tying into the electric power grid was an easy process as we were able to utilize existing infrastructure at the site," Krouse commented. "This is specifically one of the major attractions of the technology — no expensive infrastructure upgrades nor new installations are required. Our transmission line is less than 300 feet long. The turbine is connected to a synchronous AC induction generator."

Because the Hastings conventional hydropower facility operates as a run-of-river facility, there is a high CF (over 80%), which the hydrokinetic power station takes advantage of, he pointed out. This also means that the power generated from the hydrokinetic turbines is baseload and predictable, which makes it more valuable to the system operator. Furthermore, from an operations standpoint, because the hydrokinetic power station is located downstream from an existing hydropower plant, all of the water passing through its turbine already has debris filtered out. Additionally, the hydrokinetic power station’s location eliminates river traffic directly in front of the dam, which increases the safety of the installation.

Technical Innovations

The hydrokinetic turbines are installed on a one-to-one ratio with existing conventional hydro turbines, which number two at the Hastings site. Unit 1 of the hydrokinetic pair was installed in January and currently is operating; Unit 2 will be installed this summer.

"Based on our early analysis of the design, fabrication, and deployment of the first turbine, our engineers already know that the next unit, which will be deployed this summer, will be more efficient, more powerful, and less expensive to fabricate and install," said Krouse. "Progress of this magnitude in a matter of months impresses investors, as well as those looking to purchase equipment, partner on our developments, or purchase our power generation."

Even though there are no plans to install additional turbines at the site, Krouse pointed out that his company still intends to be open to introducing new technology at the power station.

"One great strength of our technology, which is the only surface-suspended design in the industry, is that our units are easy to modify or upgrade," he said. "If we develop a new blade design or other technical advances that achieve higher power output, for example, we can bring the existing turbine to the surface and modify the existing unit in approximately one day. So, if we are to increase power output at Hastings, it will be due to advances in design of our patented technology."

Licensing Process

"Since we installed the units downstream from the city of Hastings’ hydroelectric plant, the Federal Energy Regulatory Commission’s (FERC) noncapacity license amendment process was utilized," Krouse said. "The city’s existing license (P-4306) was amended since new power generation was being installed within the existing project boundary without increasing the hydraulic capacity of the facility (we did not raise the level of the water behind the dam to generate more power)."

However, instead of a two-stage pre-filing consultation, the company chose the three-stage consultation because the Hastings hydrokinetic power station was the first project of its type in the U.S., Krouse explained. Company management felt that using the three-stage pre-filing consultative process would give stakeholders more time to better understand the technology and provide additional early feedback. Numerous state and federal agencies participated in the process. Most stakeholders understood the significance of the project and participated in the licensing process by looking at the big picture, thinking creatively, and working efficiently toward compromise. Many were comfortable with performing studies once the project was installed.

"Unfortunately, some stakeholders, specifically certain staff at the U.S. Department of Interior’s [DOI’s] National Park Service, tried to stop this project from being licensed, or considerably slow its progress. And, despite the comprehensive fish and water quality studies that we proposed on day one, DOI attempted to burden the city and Hydro Green Energy with additional expensive and unnecessary studies, some that they wanted well before project installation," he said. "There was a disconcerting disconnect between the DOI’s stated renewable energy policies at the federal level and the actions of its field staff. Despite these activities, the license amendment was filed in April of 2008, and FERC issued its order approving the project in December 2008."

Financing the Project

"Our company is a privately funded renewable energy company," Krouse said. "We funded the Hastings project entirely on our own. In the future, this type of project would serve as an equipment sale to the hydropower plant owner, and Hydro Green Energy would enter into a maintenance contract and also receive a yearly royalty payment for the use of its broadly patented technology."

In terms of cost per kW installed, the capital costs for the Hastings project were lower than those of a similarly sized solar power project and generally comparable to costs of biomass or geothermal, Krouse explained. The cost for the second turbine unit at the Hastings hydrokinetic power station will be at or below $3,500/kW installed. The company’s goal is to be directly competitive with some thermal technologies, such as nuclear power, in five years; through economies of scale in manufacturing and larger projects, Krouse thinks this goal is "very much achievable."

"Our company does not disclose contractual power pricing data," he said. "For a variety of reasons, pricing at future projects is likely to be site specific, but nonetheless competitive with other incremental hydropower upgrades such as a generator rewind or a turbine blade redesign. All of those upgrades require outages at the facility. Our system was installed without ever taking the existing facility offline. This is a major opportunity cost savings and will translate into demand for our products from the hydropower industry."

The city of Hastings has a power purchase agreement (PPA) with Xcel Energy for its conventional hydropower facility, he stated. All power generated by the hydrokinetic units will be sold as part of that PPA. Hydro Green Energy and the city will split all power sales attributable to the hydrokinetic units.

Tax Credits

"Because the project is owned by the city of Hastings, a public power entity, the hydrokinetic turbines’ output is not eligible for the state or federal production tax credit (PTC)," Krouse said. "At the time of the installation of the first turbine, the Clean Renewable Energy Bonds (CREBs) program was fully subscribed, so funding via CREBs was not attainable."

He pointed out that prior to adoption of the Energy Independence and Security Act of 2007, which for the first time included hydrokinetic power technologies under the Section 45 PTC, a hydro project at a nonpublic hydropower facility would have been eligible for the PTC under the definition of incremental hydropower that was inserted into Section 45 PTC law under the Energy Policy Act of 2005. If Hydro Green Energy had partnered with a private energy company on its first hydro project, instead of the city of Hastings, the project would have been eligible for the PTC, according to Krouse.

Because all future hydro projects (and in fact, all hydrokinetic projects, regardless of location or application point) will be eligible for the Section 45 PTC and CREBs, and maybe for funding under a federal renewable portfolio standard program and a carbon cap-and-trade system, these types of projects are becoming increasingly attractive to a wide variety of entities, he explained.

Wildlife Protection

Some wildlife advocates are worried that the underwater hydrokinetic turbines might harm fish, diving birds, and other types of wildlife. Krouse was quick to respond to such concerns.

"The Hydro Green Energy turbine has three blades spinning at 21 rpm in a modestly ducted turbine that is 12 feet in diameter," he said. "Conventional units can have 8, 10, or more blades that can rotate at hundreds of rpms. Our turbine is a large and slow-moving device and should lead to minimal, and possibly no, environmental impacts. We have used the U.S. Army Corps of Engineers’ fish mortality equation to model mortality to fish. The model predicts less than 1% mortality. In that model, the error range is +/–1%, so it is possible, and we believe, that there will be no impacts to marine life at all."

He emphasized that modeling performed on his company’s turbine has shown no impact to water quality (temperature, dissolved oxygen, or turbidity). Nonetheless, his company will continue to gather water quality data at Hastings for one to three years.

"At Hastings, in April or May, we will perform the most thorough and precise fish mortality test ever performed on a hydrokinetic power device," he continued. "The results of that test, which will cost the company more than $500,000, will be made public both on our website and in scientific and industry journals to once and for all settle the question of aquatic impacts by hydrokinetic systems of our design and size. We have also implemented a bird-monitoring plan, acoustic monitoring, and a zebra mussel control program."

Looking Downstream

In terms of hydrokinetic power’s potential, a 2007 study by the Electric Power Research Institute found that the U.S. could develop at a minimum 13,000 MW of river (in-stream) and ocean-based (wave, current, and tidal) hydrokinetic power by 2025. The industry has great growth potential and is just starting to emerge from its infancy. In order to achieve this growth potential, a revision to licensing requirements is a must, as the time and expense involved under the current system are major obstacles.

Overall, Hydro Green Energy’s CEO is optimistic about the future development of hydrokinetic energy in the U.S.

"Within the next 10 years, I think it is quite reasonable to expect significant growth in the industry," he said. "In terms of how much generation actually comes on-line, I think it is too early and too difficult to predict. And, some of the growth will depend on the continuation of a number of policies at the state and federal levels designed to ensure renewable energy growth in the U.S."

Currently, the company is developing 12 hydrokinetic power projects in the U.S. — 10 open river and two tidal. Those projects are located in Mississippi, Louisiana, New York, Alaska, and Maine and range in size from 5 MW to 70 MW. Within the next five years, Hydro Green Energy hopes to have at least 350 MW on the U.S. power grid.

"Our company also is talking to a large number of hydropower companies, utilities, municipalities, and other hydrokinetic developers about selling our equipment for either new hydro projects or in-river hydrokinetic projects," Krouse said. "We expect strong U.S. and international equipment sales over the next decade, and — based on current levels of interest — sales for hydro projects could be quite significant."