Thermal efficiency improvement for economic gain has been an important power engineering endeavor for more than 250 years. The Newcomen steam engine appeared in 1750 and attained 0.5% efficiency. James Watt patented improvements in 1769 and achieved 2.7% efficiency by 1775, launching the Industrial Revolution. Watt limited operating pressure to about 0.034 MPa (5 psig). Richard Trevithick is credited with engine improvements that permitted increasing steam pressure to 1 MPa (145 psig), to achieve 17% thermal efficiency by 1834.

American Electric Power’s (AEP) Philo Plant Unit 6 steam generator was the first commercial supercritical unit in service early in 1957 (Figure 1). Philo 6, a double-reheat design, delivered 120 MW, operating at 85 kg/s, 31 MPa, 621C/565C/538C (675,000 lb/h, 4,500 psi, 1,150F/1,050F/1,000F) and was supplied by The Babcock & Wilcox Co. (B&W).

1. AEP Philo 6 universal pressure steam generator, B&W Contract UP-1. Source: B&W PPG

In 1959, Philadelphia Electric Co.’s Eddystone steam generator, a dual-reheat design supplied by Combustion Engineering Inc., initially delivered 325 MW at 252 kg/s, 34.5 MPa, 649C/565C/565C and later operated at 32.4 MPa, 610C/554C/554C. The net plant heat rate for Eddystone was 8,534 Btu/kWh, a 39.99% higher heating value (HHV) net plant efficiency without environmental system auxiliary power.

These units, using stainless steel materials, led the world toward commercial supercritical boilers. Nickel-based alloys are currently being evaluated for ASME Code acceptance up to 760C (1,400F) steam conditions.

Once-through supercritical plants became valued in the U.S. market again in about 2000, and most new larger electric utility coal-fired plants have been supercritical with variable-pressure operating mode. New plants must have favorable electric grid system operational characteristics for turndown and rate-of-load-change response. The A-USC development programs serve an important mission to improve the economics of electric power generation while reducing adverse effects on the environment.

Consortium Pushes Materials Technology

Two Babcock & Wilcox Power Generation Group Inc. (B&W PGG) design teams have been steadily working on two development programs. In one case, the U.S. Department of Energy (DOE) and the Ohio Coal Development Office (OCDO) are sponsoring a materials development program by a consortium of boiler vendors that are seeking qualification of ASME Code Section I alloys suitable for 760C turbine throttle steam temperatures. The second effort is an internal B&W PGG-funded program for A-USC boiler design and additional materials development.

The highest design steam conditions for the two programs are 36.2 MPa, 735C/760C with a final feedwater temperature of 343C. Increased efficiency reduces carbon dioxide (CO2) emissions, the costs of carbon capture, water use, particulates, sulfur oxides (SOx) and nitrogen oxides (NOx) emissions, and fuel consumption.

Research and development is being conducted worldwide to advance the technology in 700C steam generator design and materials development of the needed nickel-based alloys. Research programs in both Europe (such as the THER-MIE AD700 program) and the U.S. (the DOE Boiler Materials for Ultrasupercritical Coal Power Plants) have set a goal to improve thermal efficiency and reduce CO2 emission through the application of materials with higher temperature capability, up to 760C.

The Electric Power Research Institute manages the U.S. project. The consortium membership includes the U.S. domestic boiler manufacturers B&W PGG, Alstom Power, Babcock Power, and Foster Wheeler. There is also a sponsored program for the development of A-USC steam turbine materials in which Alstom Power, General Electric, and Siemens have participated. The goal of the materials development consortium is to address the pre-competitive industry-wide data needs such as ASME Code allowable stress and other properties to qualify the new materials. The OCDO is also sponsoring this research.

Advanced cycles, with steam temperatures up to 760C, will increase the efficiency of coal-fired plants from an average of 36% to 39% (for the current domestic fleet, excluding older subcritical units slated for retirement) to about 47% (HHV). This efficiency increase will enable coal-fired power plants to generate electricity at competitive rates while reducing CO2 and other fuel-related emissions by as much as 17% to 22%. Steam temperatures and pressures up to 760C/35 MPa are required to accomplish this goal.

Improving Plant Efficiency

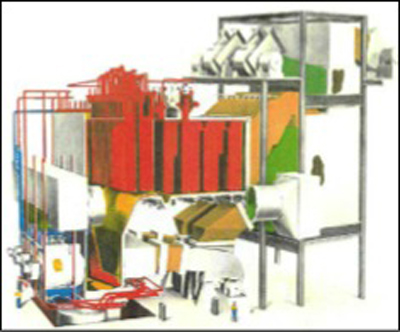

Combining carbon capture and sequestration (CCS) with A-USC plants will provide the lowest cost of electricity generation with 90% carbon capture than any other future CCS option. A B&W PGG economic study applying B&W PGG/Air Liquide (AL) technology and starting with baseline coal combustion plant designs developed by the DOE, showed the relative efficiency and levelized cost of electricity (LCOE) for A-USC with oxy-combustion CCS to be lower in comparison with other technologies (Figures 2 and 3). Should carbon-limited power generation be required in the future, the LCOE (cents per kilowatt-hour) is the lowest for A-USC with B&W PGG/AL oxy-combustion. The HHV efficiency of 39.4% for the current 600C (1,112F) state-of-the-art plant is nearly regained by using A-USC with oxy-combustion, which provides an efficiency of 38.9%.

2. Comparing net plant efficiency for CCS options, we see that, on an equivalent basis, oxy-combustion offers the best plant efficiency when compared with other CO2 capture options. For comparison, air-fired cases are the far left group, conventional carbon capture technologies are in the middle, and future carbon capture technology predictions are on the right. Data were taken from DOE/NETL 2007-1291 “Pulverized Coal Oxy-combustion Power Plants,” Rev. 2; DOE/NETL 2007-1281 “Cost and Baseline for Fossil Energy Plants,” Rev. 1; and B&W/AL Integration study using the warm recycle process with supercritical and ultrasupercritical steam conditions. Supercritical steam conditions are 241.3 MPa, 600C/620C; ultrasupercritical conditions are 27.6 MPa, 730C/760C. Source: Babcock & Wilcox Power Generation Group and Air Liquide

3. Note in this comparison of the levelized cost of electricity for carbon capture and storage options that the B&W/AL bars show the best improvements in the LCOE when using oxy-combustion. All numbers are based on the same financial assumptions about burning the same bituminous coal and are estimated in 2007 dollars, not including owner’s costs. The Figure 2 data sources also apply to this figure. Source: Babcock & Wilcox Power Generation Group and Air Liquide

In Figures 2 and 3, Cases 1, 3, 5, and 7 use 600C supercritical technology; Cases 2, 4, and 6 use A-USC 730C/760C technology; Case 3 and Case 4 use post-combustion CCS; Case 5 and Case 6 use oxy-combustion CCS per DOE study estimates; Case 7 also uses oxygen membrane technology; and the B&W PGG cases are 600C and 730C technology with B&W PGG/AL oxy-combustion improvements.

Evaluation of the economic cost of these new candidate materials necessary for A-USC steam power plants shows that the potential thermal efficiency improvement appears viable and is within the expected margin for achieving an equal or better cost of electricity and significant reductions in emissions per kilowatt-hour. Cost reductions due to smaller equipment in other areas of the plant, along with fuel savings, will help offset the higher capital cost of the A-USC boiler, including the required nickel-based materials.

Current State-of-the-Art Steam Generator

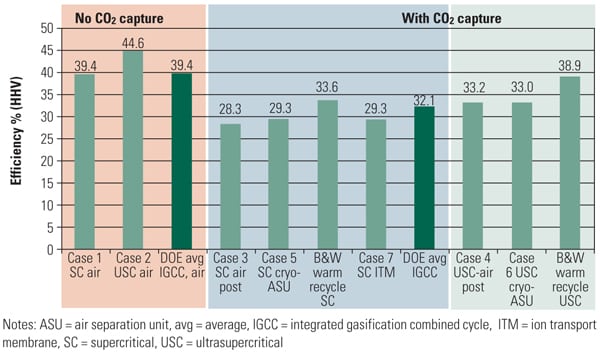

Figure 4 is an example of the current commercial state of the art for USC units in the U.S. market (Case 1 of Figures 2 and 3). USC designs will utilize main steam temperatures to about 605C, and hot reheat temperatures to about 621C. The most advanced cycle conditions for the current market in the U.S. are for the John W. Turk, Jr. AEP Hempstead project, scheduled for operation in late 2012. B&W PGG supplied the 690-MW (gross) boiler designed at 26.1MPa, 602C/608C, 299C feedwater inlet temperature.

The design features for Turk are more conventional for the B&W PGG Carolina (two-pass) boiler arrangement with multi-lead ribbed tube spiral wound lower furnace, mix transition to the vertical tube upper furnace enclosure, two-pass arrangement pendant heating surface, and the two parallel path gas biasing horizontal convection pass with reheater, primary superheater, and economizer banks. Stainless steel tubing is used for the superheater and reheater. The high-temperature headers and steam leads are 9Cr ferritic steel.

4. Current state-of-the-art 600C ultrasupercritical design. Source: Babcock & Wilcox Power Generation Group

Commercial A-USC Plants

The path forward to commercial A-USC plants is to determine whether further component testing at small scale in an electric utility setting is necessary or whether the industry is ready to move forward with a small commercial size demonstration at about 400 MW.

The customer for the product of an operating electric generating unit is the transmission grid independent system operator that is meeting the load demands at various system delivery locations by taking and transmitting power produced by many generating plants. This evolving and competitive market is served by units at plants that must bid a pricing offer one day ahead and that have various operating restrictions, cost structures, and characteristics that may or not align well with the power grid’s needs at each hour of the day. Low net plant heat rate, low fuel cost, wider load turndown range, and fast rate of response are valuable characteristics that will enable units to achieve positive net income. The owner/designer planning a new generating unit must factor these considerations into the design.

The tendency for supercritical units has been to select a larger size, greater than 400 MW and averaging about 750 MW, because economies of scale have normally resulted in the delivery of a lower cost per MW installed and a lower LCOE. The preferred commercial size unit has been stated to be at 1,000 MW; Europe and China have been planning and constructing 1,000-MW units. The U.S. industry A-USC consortium is indicating that unit sizes between 350 MW and 1,000 MW would be possible. U.S. domestic A-USC plants will likely be teamed with CCS soon after the first commercial size demonstration.

Design concepts for A-USC steam generators are being developed, starting with the current arrangements typical of present-day application, and new and significantly different steam generator arrangements are to be expected, particularly when adapted to use the advantages of oxy-combustion CCS.

More to Come

In the next two parts of this three-part report, we will explore the materials development process, the steam generator design, and the overall cycle design of the A-USC power plant.

The DOE and the Ohio Coal Development Office support for the A-USC Materials Development project is greatly appreciated. The efforts of industry-wide organizations have fostered an environment of cooperation in working toward the common pre-competitive needs for ASME Code materials development for A-USC.

—Paul S. Weitzel is a technical consultant in the New Product Development, Advanced Technology Design and Development, Technology Division of Babcock & Wilcox Power Generation Group Inc.