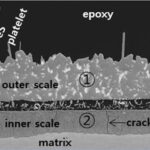

Metal loss of the pressurized tubes inside the boiler is a big concern for boiler designers and operators. Changing fuel composition and other service parameters can lead to accelerated erosion and corrosion (Figure 1), which need to be mitigated using proven and robust materials.

|

|

|

1. These two photos highlight erosion (top) and corrosion (bottom) of boiler tubes. Courtesy: Integrated Global Services (IGS) |

Weld metal overlay is known for its longevity. It is also known for its cost, and the time required to carry out the application. Thermal spray also can be used to protect boiler waterwalls. It is faster to apply, though not always considered as robust. In recent years, this technology has undergone some major developments, which may increase its rate of adoption for boiler waterwall protection.

The power generation industry over the past several years has been faced with increasing pressures from environmental agencies regarding emissions. These initiatives subsequently forced the sector to evolve and develop cleaner processes.

One of the first steps was to optimize combustion by using low-NOx burners with optimum parameters for NOx reduction. The combustion chamber, which was typically an oxidizing environment, has turned into a reduction environment. The boiler and its tube material were not designed for such conditions, leading to an increase of corrosion rates.

In addition to this modification, many plants took the opportunity for fuel diversification, and in some regions low-cost coal has been a preferred option. However, the price of coal is also relative to its quality, with higher-cost coal having a greater heating value, while other coals may have a lower concentration of carbon, but also a lower heating value.

The combination of the environment changing from oxidation to reduction, and from low- to high-sulfur content coal, has created a significant increase of the corrosion rates. This situation can be aggravated further by erosion due to abrasive ashes or corrosion under deposits when ash builds up in certain areas.

Some coal plants are converting to biomass, but biomass can include recycled materials with a potentially high content of corrosive agents.

Use of Thermal Spray as a Corrosion/Erosion Barrier

In the 1990s, high-velocity thermal spray was an established technology in a highly controlled shop application environment. It was used for specialized applications in aircraft components, valves, and other similar equipment, and users began asking whether it could be effectively applied in the field to existing fixed assets in-situ.

Field technology was also present at the time, but it was a different class of technology. Twin wire arc spray (TWAS) or thermal spray aluminum (TSA) are both low-velocity thermal spray technologies that are not able to produce reliable coatings to serve in critical erosion/corrosion environments in fixed assets such as circulating fluidized bed (CFB), bubbling fluidized bed (BFB), or grate-fired boilers. The existing high-velocity thermal spray equipment and technology couldn’t be taken into the field effectively or economically.

A handful of engineers addressed that problem. Atomizing the wire in a supersonic gas stream was the first piece of the puzzle. This technical development delivered a surface technology that worked well with commonly used welding materials in high-temperature corrosion environments such as the coal power sector of the time.

New Hurdles

At that stage, Integrated Global Services (IGS), with key clients, was exploring wider utilization of the technology into other industry sectors such as waste-to-energy and biomass. The group discovered that spraying off-the-shelf alloy feedstock materials using a high-velocity process produced particles that oxidized in flight, creating an applied microstructure with permeability pathways for corrosion. While this wasn’t an issue for high-temperature erosion applications, it was a fundamental problem for environments with corrosive media, such as chlorine or sulfur, among other corrosive substances.

IGS conducted significant research and development (R&D) work in the early 2000s, with a goal of developing new high-velocity thermal spray feedstock materials, which would control the alloy integrity during the application process. In this way, the applied microstructure would be fit for the service environment of the asset. The R&D project focused on the permeability of the applied high-velocity thermal spray microstructures, assessing the resistance of the applied materials to permeation by aggressive/corrosive fluids, the shape of the deposited particles being sprayed, and controlling residual stresses.

|

|

2. A worker applies high-velocity thermal spray, or HVTS, to boiler waterwalls. The spray provides a lasting corrosion barrier on equipment and is being used in a variety of power plants. Courtesy: IGS |

Following development of bespoke feedstock alloys, high-velocity thermal spray (Figure 2) would no longer be a shop-only solution when long-term reliability was essential. It has now become a surface technology that can be effectively deployed as a lasting corrosion barrier in the field, during shutdowns and turnarounds, reducing critical path, and ensuring lasting reliability in the most arduous operating environments. As the adaptation of this technology continued to grow, biomass and waste-to-energy plant operators started to recognize it as an optimum erosion/corrosion barrier to protect their fixed assets’ parent metal.

The development of this technology is still ongoing. Developing new processes, experimenting with new sources of fuel, and utilizing waste as a fuel source is an important next step in our global sustainability movement. New materials and technologies, however, present a unique challenge for designers and operators in terms of unexpected and accelerated erosion/corrosion. Proven and robust surface protection solutions, which can be deployed in the field within turnaround schedules, are therefore seen as a welcome alternative to repeated equipment replacement or weld metal overlay.

—Marina Silva is international marketing manager for Integrated Global Services (IGS). The company, headquartered in Virginia, is an international provider of surface protection solutions.