How power companies are using experience management, or XM, to reshape customer relationships and reveal new revenue opportunities Here was a company with one of the largest investor-owned electric systems…

Technical articles on all aspects of power plant operation, preventive and predictive maintenance, planned and unplanned outages

How power companies are using experience management, or XM, to reshape customer relationships and reveal new revenue opportunities Here was a company with one of the largest investor-owned electric systems…

Lock in safe, reliable operations by opening the door to third-party expertise There’s still a big takeaway from a 2008 Florida blackout, and it’s not the size of the fine…

Two new power plants in Michigan’s Upper Peninsula (U.P.) came online earlier this year, supplying power for customers of Upper Michigan Energy Resources Corp. (UMERC), a subsidiary of WEC Energy…

Economic power plant operation includes keeping maintenance costs under control, and operating the plant efficiently. Boiler surfaces need to be kept as clean as possible to increase heat transfer and…

Today, drones equipped with sensors and cameras are proving their worth in gathering real-time footage that can be stored for later analysis. Uncrewed aerial systems can detect failing structures and…

Sonic sootblowers and acoustic cleaners were once thought to be a last-chance alternative to difficult ash build-up problems. However, the technology has proven to be effective over years of service…

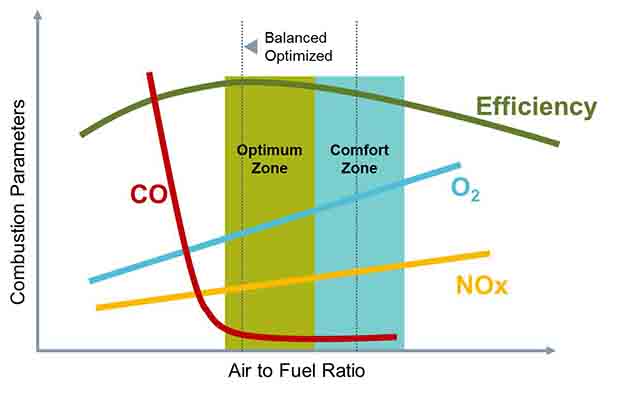

Power plant operators are always looking for ways to boost performance. A combustion optimizer designed to improve efficiency and lower emissions could help. It supports more flexible operation of boilers…

IHI Corporation (IHI), in cooperation with Steinmüller Engineering GmbH (SE), a wholly-owned subsidiary of IHI having a profound technical knowledge of boilers for thermal power generation, has concluded a Long…

Organizations operating within a mission-critical environment must adopt appropriate technology to mitigate potentially life-threatening problems. As we acknowledge National Preparedness Month this September, we need to remember what is important…

The CA76NA and CA80SI analyze boiler feedwater, steam, condensate and ion exchangers — making them a great fit for power industry applications. August 15, 2019—Endress+Hauser announces two analyzers for power…