Allentown, PA.: ASGCO® “Complete Conveyor Solution’s” unveils their newly enhanced series of Sure Grip™ Conveyor Belt Clamps in their line of Safe-Guard® safety conveyor products. Designed to secure the belt…

O&M

Technical articles on all aspects of power plant operation, preventive and predictive maintenance, planned and unplanned outages

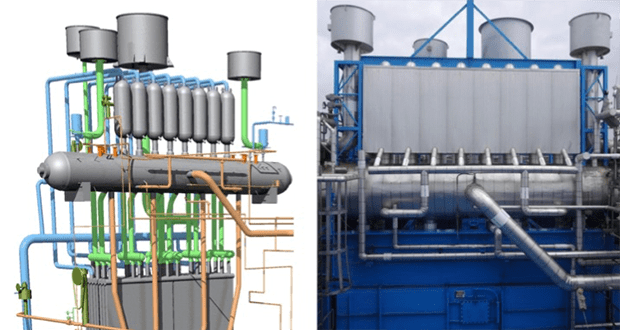

Brownfield Engine Exchange (BEX) delivers cleaner energy, long-term reliability, improved efficiency and more powerful performance Making Energy Greener is one of Siemens’ continuing core focus areas as the global energy…

Today’s heat recovery steam generators (HRSGs) are suffering reliability problems, mainly because they’re being operated in the cycling mode instead of the baseload mode for which they were designed. The…

Pilsen (08/06/2019) – Doosan Škoda Power, a Czech manufacturer and supplier of steam turbines and components for power-generating operations, has won a contract to upgrade the TG5 heating plant at…

State-of-the-art automation systems are common at power plants these days. Still, many plants start up units in a very manual way. When startups were rare, the implications were minimal, but…

A pilot project was initiated by China’s largest energy provider to test the effectiveness of fog-based power augmentation for a gas turbine at a compressor station. The system provided a…

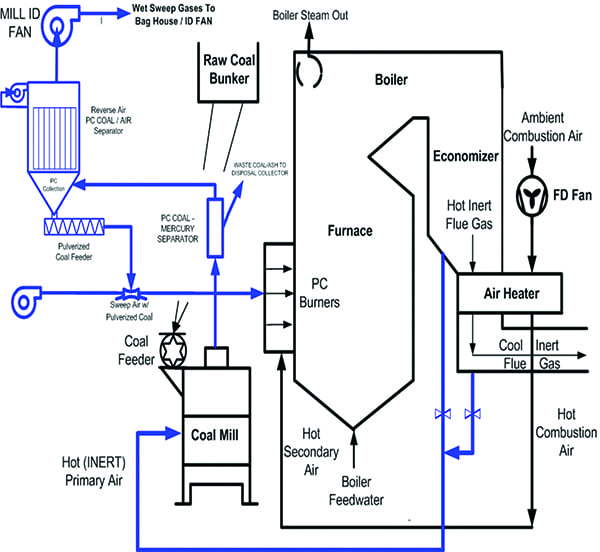

Coal-fired plants have been powering the electric grid for more than a hundred years, but the technology being used in them is not stagnant, as many advancements have been made.…

A major part of maintaining a power plant at peak efficiency is dealing with or preventing damage from corrosion and corrosive objects that can enter air and water intake systems,…

An arc flash is the explosive energy released when an electrical fault causes an arc. This rapid release of energy causes excessive temperatures in addition to air and metal in…

COMMENTARY Economic pressures coupled with new and proposed regulations to reduce air emissions and regulate cooling water use and the management and disposal of coal combustion residuals (CCRs) continue to…