Birmingham, Alabama: Terence R. Donnelly, President and Chief Operating Officer for Commonwealth Edison Company, an Exelon company, was elected President of AEIC during the Association of Edison Illuminating Companies (AEIC)…

O&M

Technical articles on all aspects of power plant operation, preventive and predictive maintenance, planned and unplanned outages

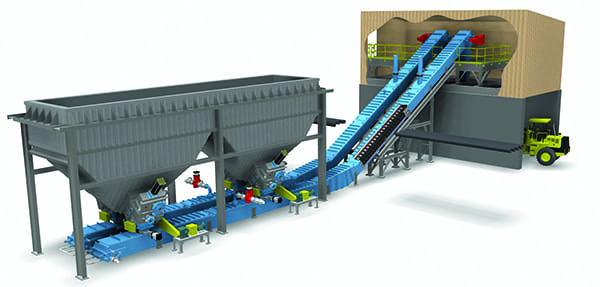

Conveyor system will move 127,500 tons of primary crushed ore per day New Siemens’ gearless drive technology to increase reliability and efficiency additionally by up to 4 percent Maintenance requirements…

Birmingham, AL -- The Association of Edison Illuminating Companies has announced five recipients of the prestigious AEIC Achievement Award for 2019. The AEIC Achievement Awards are presented annually to individuals…

Lakeland Industries’ new mid-weight and high visibility moisture management line of FR/AR apparel enhance the company’s current product layering system specifically designed for electrical utility linemen. The products feature exceptional…

Coalescer prefilters provide gas turbines and compressors with optimum protection against moisture under harsh operating conditions, as shown by two examples from actual applications Weinheim, October 15, 2019. One of…

According to the Farmer’s Almanac, the winter of 2019–2020 will be filled with bitterly cold weather in the eastern parts of the Rockies and east to the Appalachians. The Northeast…

The PRB Coal Users' Group is changing its name to the American Coal Users' Group. The Board of Directors recognizes that times are changing for the coal industry, and the…

The energy industry is currently moving from a traditional, highly regulated production model dominated by electricity utilities to a decentralized, deregulated model featuring a higher proportion of renewable energy sources…

New environmental regulations have forced many coal power plant operators to consider alternative options for handling their boiler bottom ash. Although mechanical drag systems can often meet regulatory requirements, space…

Utilizing new technologies in today’s business environment is a necessity for operations leaders looking to optimize their resources. Smartphones, GPS, radio-frequency identification (RFID), on-demand/cloud computing, barcodes, scanners, and the latest…