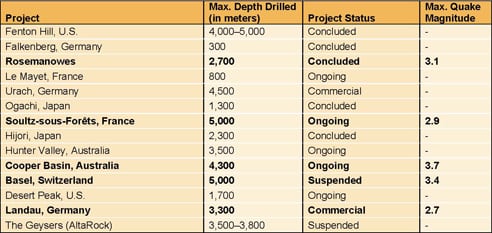

Enhanced geothermal systems (EGS) deliberately induce seismicity — earthquakes — in order to access hot, subsurface rocks for use in geothermal power generation. Recent quakes around the world have frightened those living near EGS sites and sparked controversy over the technique. We asked experts to provide EGS technical details and to evaluate the seismic risk the process poses.

On Aug. 15, just after 2 p.m. on a Saturday, an earthquake registering 2.7 on the Richter scale rocked the German city of Landau in the province of Rheinland-Pfalz, close to the French border. Residents reported hearing a loud boom, prompting more than 200 calls to the local police. No damage or injuries were reported, but shockwaves of panic began to radiate throughout the country — and beyond.

Alarm spread as the state geological survey for Rheinland-Pfalz claimed the epicenter of the quake was centered 450 meters (500 yards) from a novel geothermal plant’s drilling site, at about 3.3 km (2 miles) underground — the same depth at which the steam reservoir from which the plant was drawing heat lay (Figure 1). It was the first time tremors had been felt from the commercial plant commissioned in late 2007. One of the first of its kind, the €15.5 million ($23.2 million) enhanced geothermal system (EGS) project had been sponsored by Germany’s environment ministry, and it provided 3.2 MW of power and heat to a district-heating scheme. It also benefited from the country’s feed-in-tariff program.

1. Shaken up. This August, a 2.7-magnitude temblor rocked the German city of Landau, close to the French border. Because it was centered on one of the first commercial enhanced geothermal systems in the world, the quake triggered concerns about the novel technology and its seismic risk. Courtesy: Geox

In Australia, attention focused on a similar proof-of-concept project that bored two wells 4.4 km into the yellow crust of the Cooper Basin, in a desert deep in the interior, to demonstrate economic heat extraction from rocks heated to about 250C (482F). The government and Geodynamics admitted that project had in December 2003 generated tremors with magnitudes of up to 3.7. In northeastern France, two test wells had been drilled at 5 km to harness heat from rocks at 200C at Soultz-sous-Forêts, in Alsace. In 2003, a 2.9-magnitude quake prompted restrictions on that project’s activities.

The Landau shake-up was even compared to a 3.4-magnitude trembler that shook residents, put cracks in buildings, and shattered roof tiles in Basel, Switzerland, on Dec. 8, 2006. The city of medieval cathedrals (Figure 2) is built in the region of that country that is most prone to seismic activity. Switzerland already sees three or four quakes of that size a year, but Basel was particularly vulnerable, officials said in 2006, having been leveled by a 6.5-magnitude earthquake once before, in 1356. Geopower Basel, the company that had been executing a trial deep heat mining project within the city — at Neuhaus Street and Shafer Lane — admitted that high-pressure injection of water 5 km into underlying superheated rocks could have caused the event. Authorities immediately halted the project, pending findings of a detailed seismic risk study, the results of which are due this December.

2. Basel rocks. On Dec. 8, 2006, a trial enhanced geothermal systems (EGS) project within the city of Basel, Switzerland, triggered a 3.4-magnitude quake that cracked buildings, shattered roof tiles, and made waves around the world. On average, Switzerland experiences three or four earthquakes of that size per year, but Basel is particularly vulnerable, having been leveled by a 6.5-magnitude quake in 1356. Courtesy: Wikimedia Commons

In September at Landau, as in Basel, concern mounted as plant operator Geox attempted to explain that it had relied on underground "fracturing" of the "hot" underground rock mass to enhance its permeability so that more water could be circulated to deliver heat to the surface for power conversion.

In other words, Geox had actually induced an earthquake by pumping fluid under high pressure for the subsequent extraction of energy.

A Turbulent Technology

To understand this relatively new technology better requires an overview of how otherwise conventional geothermal energy is exploited. (For a summary of current and potential geothermal technologies, see this issue’s online supplement titled "The Future of Geothermal.")

The world’s geothermal resource consists of thermal energy — or heat — stored under Earth’s surface. All but about 1% of the planet’s volume is at temperatures of more than 1,000C. Within Earth’s crust, heat is constantly rising toward the surface by conduction and then being discharged convectively by fluid — via water or steam, such as at hot springs — through fractures or pores. About 40% of geothermal energy sources derive from heat flow from Earth’s core and mantle, while 60% of the planet’s heat is otherwise generated by the decay of radioactive isotopes in its continental crust.

This means, according to the International Energy Agency (IEA), that geothermal energy potential is massive: At today’s average global terrestrial heat flow rate of 44 million MWt — almost three times the world’s primary energy consumption rate — it would take over a billion years to exhaust that heat content. However, tapping this stored heat is a challenge.

The planet’s surface heat flow is not uniform: Concentrated in regions of tectonic plate boundaries and volcanic hot spots, it accounts for only about 15% of global land surface. The IEA claims that in 2007, worldwide geothermal capacity of 10 GWe — only 4% of an estimated worldwide potential of identified, feasibly technically geothermal resources — had been installed, reaping energy via mainly hydrothermal-based systems. More importantly, it was limited to about 24 countries — largely in Central America, Iceland, Indonesia, Italy, Japan, Kenya, Mexico, New Zealand, the Philippines, and the U.S. Almost half of the installed capacity had been operating for more than 25 years, the agency said.

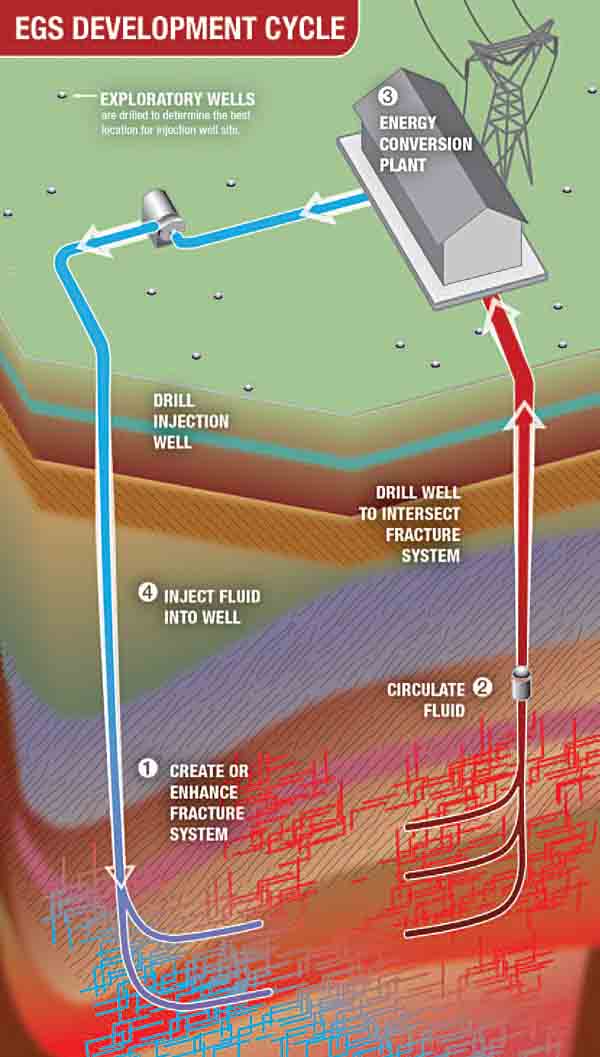

But since the 1970s, EGS, a new method that seeks to exploit the enormous terrestrial heat potential efficiently and economically, has been developed. (See sidebar "EGS Around the World.") It requires locating fractures in high-temperature rock at geologic depths of between 3 km and 10 km so that water and steam circulating through them can transfer heat rapidly to the surface. Where fractures are not naturally abundant, they are significantly "enhanced" — new ones are created where it is technically feasible, or existing ones are reactivated. The process essentially requires pumping fluid under high pressure to prop open joints — thus leaving permanently dilated joints through which a working fluid can circulate to enable heat extraction (Figure 3).

3. Cracks that run deep. An enhanced geothermal system is an engineered heat exchanger designed to extract geothermal energy under circumstances in which conventional geothermal production is uneconomic or inefficient. The method involves “enhancing” the permeability of deep hot rock by hydraulic fracturing, high-rate water injection, and/or chemical dissolution of minerals. Once permeability has been increased, production can be sustained by injecting a working fluid into injection wells so that it is circulated through the newly created permeability. The heated working fluid then travels to production wells. As the circulating water cools, the process may create new permeability, continually expanding the reservoir and exposing more heat to be mined. Source: U.S. Department of Energy

EGS employs three major techniques to enhance rock permeability: hydrofracturing, fluid injection, and acidization, which involves dissolution of rock minerals. According to Dr. Ernest Majer, director of the Earth Sciences Division at the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (LBNL), all three work by triggering seismicity — earthquakes — caused by stress changes from small perturbations in pressure, or by redistribution of thermal and mechanical stresses through contraction or expansion of the underlying reservoir rock. These man-made tremors are termed "induced seismicity." It’s a phenomenon that is absolutely integral to EGS — and nothing new, said Majer, whose lab has been spearheading U.S. development of EGS and is at the forefront of studies exploring the link between seismicity, EGS, carbon sequestration, and oil and gas drilling.

Of Quake Quantity and Quality

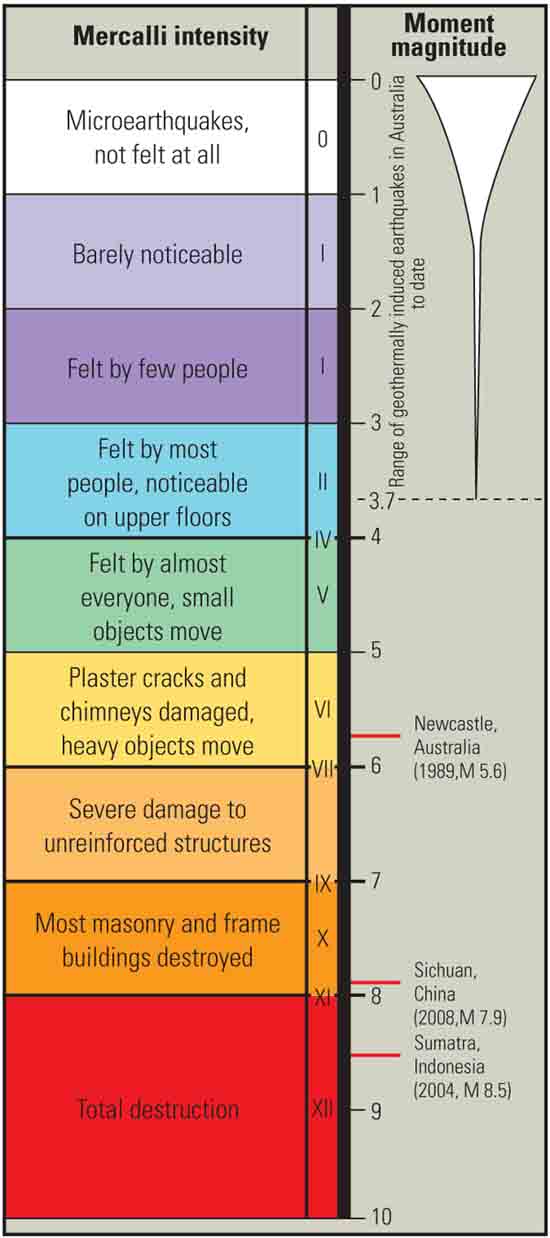

Majer explained that since seismic activity has been monitored at geothermal and EGS sites, thousands of induced earthquakes have been documented all over the world — but these have been predominantly microearthquakes that are not felt by people (Figure 4). "There have been so many small earthquakes, what we call ‘annoyance-type’ seismicity. Sites monitoring seismic activity have recorded several hundred magnitude 2s per year, 20 or 30 magnitude 3s, and even three or four magnitude 4s — but none of them large enough to cause any major damage," he told POWER in October.

4. On a scale from 1 to 10. Experts say that seismicity induced by EGS techniques such as hydrofracturing, fluid injection, and acidization have caused thousands of earthquakes all over the world, but most have been so small they were not felt by people. The government of Australia—a country actively sponsoring, promoting, and educating citizens about EGS and associated seismic risks—provided this scale, which compares the range of known induced earthquakes from the Cooper Basin tests deep in that country’s interior to well-known earthquakes in the Asia-Pacific region. The wedge shape illustrates the distribution of induced events with respect to magnitude, and the width is proportional to number of events. Courtesy: Geoscience Australia

In 2003, for example, hydrofracturing experiments conducted at the 4,421-meter (m)-deep Habanero I test well at the Cooper Basin in South Australia showed that the process had induced more than 27,000 small quakes over a few weeks — only three of which were greater than magnitude 3.0.

"Sometimes people are a little alarmed at the idea that you want to cause earthquakes while [demonstrating an EGS system]. That is one way to look at it — you want to open up the fractures, but along the process, that lets out some seismic energy," said Majer. The scientist and his team have been involved in several briefings with staffers in Congress recently regarding hazards associated with induced seismicity and EGS. The briefings sought to allay concerns raised following the publication of a New York Times article in June that drew similarities between the induced 3.4-magnitude quake at the Swiss geothermal prospecting project at Basel and an EGS demonstration at The Geysers in California. The latter, a $17 million project led by start-up company AltaRock Energy, had garnered millions in federal funding. The company has also raised some $30 million in venture capital from firms like Google and Kleiner Perkins Caufield & Byers.

AltaRock had disputed the comparison, saying that Basel sits on top of a large (200-km long) "locked" fault that had previously ruptured and leveled the city in the 14th century. "We carefully chose our site to avoid Basel’s problems," the company said in a statement. "There has been geothermal energy production at the Geysers since 1965. AltaRock’s project is located in a seismically active area adjacent to smaller faults (the closest faults are 3 and 11 km long) which are not ‘locked’ due the constant stress relief resulting from small seismic movements." In October, after encountering repeated drilling problems (it was able to bore down only about 4,400 feet) — not because of earthquake fears, as has been widely alleged — the company indefinitely suspended operations.

Induced seismicity could certainly be devastating, Majer admitted, pointing to the 6.3-magnitude 1967 Konya Dam quake in India and the U.S. Army’s infamous Rocky Mountain Arsenal disposal well, which was shut down in 1966 after fluid injection at a depth of 12,000 feet was said to trigger a 5.3-magnitude earthquake in the Denver area. But, he said, the AltaRock project, which sought to drill at similar depths, couldn’t have caused seismic activity to that extent. He added that it was a classic example of how public understanding about the technology was skewed.

"The Geysers is a natural system — they replenish the water by just pouring the water back in," he explained. "AltaRock’s EGS project proposed to go below the natural system into the harder rock and see if they could prop open the natural fractures — not create fractures like they do in oil and gas — and circulate water through it to get the heat out."

Fractious Findings

The distinction between the hydraulic fracturing (also known as hydrofracking, or fracking) used in oil and gas exploration and the type used for geothermal systems is important when assessing seismic risk, according to Majer. Fracking, by definition and design, is a form of induced seismicity. It occurs when the fluid-injection pressure exceeds the rock fracture gradient and tensile failure occurs, creating a "driven" fracture. "All the seismicity recorded is from shear fracturing — not hydrofracking," he said. "Hydraulic fracking is used to connect the preexisting fractures in oil and gas, whereas in geothermal, they don’t want to drive the fracture. In order to get that high heat out, you need a lot of contact with the rock — you just want to kind of tickle the system and open preexisting fractures rather than drive one." This requires a much higher volume of fluids than is used for oil and gas — up to 60 to 80 liters per second (950 to 1,260 gpm), he explained.

Injection at subhydrofracture pressures can induce seismicity, however, Majer notes, though he says that studies have shown seismicity would mostly be of a low magnitude. The exception was a 4.6-magnitude earthquake — the largest recorded geothermally induced event — which occurred at The Geysers in the 1980s, when production was at its peak.

Ultimately, Majer said, the method is relatively safe. Before any EGS project is started, a series of injectivity tests are performed to determine the stress level at which hydrofracturing occurs — and that level is maintained. "This does two things: it gives you the minimal horizontal stress, which controls the earthquakes and flippage on the rock, and it also tells you the direction of the minimum and maximum stresses, which is very important in understanding how the whole system is going to respond," he said. "Seismicity is actually useful to understand where the fluids are going. And there’ve been several proposed mechanisms or protocols that provide guides on the release of energy."

Three international workshops between 2005 and 2006, for example, yielded a good practice guide maintained by the IEA, and the DOE is considering requiring that all federally funded EGS projects follow a new, U.S. protocol. The guidelines will define a safe vibration limit scale based on proximity to communities — as opposed to limitations based on a magnitude scale. The defining criteria used for assessing the magnitude of induced seismicity would be ground acceleration and frequency content. For structural damage to occur, for example, frequencies of less than about 10 Hz are normally required. Generally, frequencies associated with induced seismicity are much higher, between 100 Hz and 300 Hz. Consequently, they are less likely to cause structural damage, though occasionally larger events generate around 40 Hz.

But could a standard protocol or guide based on those factors relegate the seismic hazard risk for EGS projects to insignificance? Dr. David Oppenheimer, a seismologist from the U.S. Geological Survey (USGS), told POWER that many mechanisms would have to be considered, including rock pore-pressure increases, temperature changes in working fluids, volume changes due to injection and withdrawals, and geochemical alteration of fracture surfaces.

Among the foremost factors that could trigger a large quake is the existence of sufficient, preexisting tectonic stress — conditions that exist at The Geysers, because the geothermal field is located near the Pacific-North American plate (San Andreas fault) boundary. This would require a fault system large enough to allow significant slip — as well as forces present to cause this slip along the fault — and these forces must be larger than the forces holding the fault together. But even this wasn’t a reliable indicator because "What we observe at the Earth’s surface may not reflect what occurs at depth," he said. "Many significant quakes rupture faults that never rupture to the surface. So, it is possible that preexisting faults could exist in the target area of the EGS project."

The Marriage of EGS and CO2 Sequestration

EGS may have garnered much recent attention for its appeal as a renewable energy source, but as a relatively new technology, it continues to pose numerous technical challenges. Governments are injecting billions of dollars into its development, which could help solve some of the puzzles. The DOE in late October, for example, committed $338 million in funding from the American Recovery and Reinvestment Act of 2009 to advance geothermal technologies.

Yet industry experts like Dr. Subir K. Sanyal, president of the California-based geothermal consulting and services firm GeothermEx Inc., assert that it will take decades to reduce levelized costs of EGS power enough to make EGS commercial, even with federal support. In a 2007 paper, Sanyal put the total capital cost — including exploration and drilling, stimulation, power plant, and surface facilities costs — for all sizes and configurations of hypothetical EGS projects at higher than $4,000 per kilowatt of installed capacity. This compares to a typical cost of $3,500 per kilowatt for conventional geothermal projects.

Nevertheless, findings from federally backed projects could be beneficial and could even lead to the integration of EGS and another relatively new concept that uses similar technologies and has similar challenges: geologic carbon sequestration. Here’s how it might work.

The primary working fluid circulated through an EGS in a continuous loop is typically brine. Heat extracted from the deep subsurface system by the brine is brought to the surface and then transferred to a secondary fluid — typically isopentane — which is then expanded through a turbine-generator to generate power. But as research continues on this basic system, efforts are also under way around the world to develop an EGS concept that uses supercritical carbon dioxide (CO2).

Such a system is said to have many theoretical advantages: Not only would it help sequester the greenhouse gas, but it could also minimize water use and offer a greater power output with minimal parasitic losses from pumping and cooling, say scientists at the recently established Queensland Geothermal Energy Center of Excellence at the University of Queensland in Australia.

The center is developing an approach that circulates highly pressurized CO2 through superheated rocks within the subsurface reservoir to extract geothermal heat. The scientists say that supercriticaCO2 would behave like a liquid under pressure in the injection well and like a gas on the surface. The hot fluid will then rise as in a flash geothermal plant, and then — without an intermediate heat exchanger — expand to a gas at the surface to turn a turbine and produce electricity.

In theory, the center says, the thermal cycle efficiency of what it calls the "supercritical CO2 geothermal siphon system," could be 50% higher than the efficiency of a conventional geothermal binary power plant working between similar reservoir and ambient temperatures — an improvement that could make a big impact on the financial viability of a given EGS project.

Asked if using CO2 in the reservoir as opposed to water or brine could induce large seismic events, University of Queensland Professor Hal Gurgenci, who is also interim director of the Geothermal Center of Excellence, responded that CO2 in the reservoir would be at the current reservoir pressures, and that in terms of the pressure loading on the surrounding rock, there would be no difference between CO2 or water. "Therefore, as far as earthquake risk is concerned, there is no difference between water or CO2 as the geothermal heat exchange fluid," he said.

Do EGS and CO2 Sequestration Share a Fault?

The question of whether and how induced seismicity will affect the future of EGS is a question also being asked about geologic storage of CO2 .

The USGS, in a March 2009 paper evaluating CO2 storage, deems earthquakes a potential hazard from large-scale CO2 injection, ranking it as important a concern as contamination of shallow groundwater and transport of contaminants out of the storage formation.

Dr. Christian Klose, a geophysical hazards research scientist at Columbia University, says the risk of stored CO2 causing quakes is very real. "Carbon sequestration can trigger earthquakes of varying magnitudes [less than magnitude 5], as any fluid injection can do," he told POWER. Three processes could trigger seismic activity, large and small: pore fluid pressure changes; fluid mass (volume) changes, which can cause stress on the rock; and migration of theCO2 through the rock over decades to centuries. "CO2 is buoyant, since its density is [lower] than saline water deep in the crust," he said. "Thus it will come upward through cracks and fractures and faults — even in so-called cap rocks there are rock discontinuities that cause leakages."

The Earth Sciences division at LBNL disagrees, however, saying that there are too few large-scale injections of CO2 for sequestration to practically assess the risk. It also points out on its website that CO2 has been injected safely underground for years in many oil and gas reservoirs with little seismic impact, adding that the lessons from EGS-induced seismicity will particularly apply to CO2 injections into deep saline water formations and coal gas and shale formations.

Moreover, according to Traci Rodosta, a geological sequestration project manager for the National Energy Technology Laboratory, quake risk is well-assessed during research and development of any given project. "Potential sequestration reservoirs are thoroughly characterized prior to injection," she told POWER. "In order to eliminate and reduce the potential for fault activation and slippage along preexisting fractures that could be caused when injecting fluids at high pressures, regulatory agencies limit injection rates and pressure to avoid unintentional hydrofracturing. CO2 storage projects would operate under similar guidelines, and the risk [would be] managed through site characterization, injection design, and monitoring."

For Majer, the likelihood of seismic activity as it relates to carbon sequestration — even at larger volumes — would be minimal. "Most CO2 sequestration sites shouldn’t be near faults. In geothermal you don’t really have a choice, whereas in sequestration, you do," he explains. Perhaps what will be of more importance is to address with urgency — as for EGS — public perceptions of potential hazards as they apply to induced earthquakes. He points out that, unlike a geothermal plant, which provides a source of revenue and development for any given community, a carbon sequestration site may not. "With CO2 sequestration, if annoying seismicity starts, it may be more difficult to deal with than geothermal, because [the community is] not getting too much out of a particular project even though it’s suffering the annoyance," he said. "There won’t be too many jobs associated with it, they’re not getting any tax revenue from it — it’s really just helping us save the planet."

—Sonal Patel is POWER’s senior writer.