Vattenfall Pioneers Innovative Offshore Wind Foundations

The first commercial-scale suction bucket jacket foundation has been installed at Vattenfall’s 11-turbine European Offshore Wind Deployment Centre (EOWDC) in Scotland. The pioneering foundation, which weighs 1,800 tonnes, was installed in late March within only 15 hours, aided by a 25,000-tonne floating crane, the Asian Hercules III.

The development marks a major milestone for suction bucket jacket foundation technology in an offshore wind application, and Vattenfall calls it a “game changer.” Typically, offshore wind power foundations are driven into the seabed by piling, which anchor a structure’s foundation. But critics of the method say it causes a lot of noise and disturbance for sea mammals, fish, and nearby coastal communities. Instead of monopiles, suction bucket technology uses giant upside-down buckets paired with jacket substructures to anchor wind turbines to the seabed, the company explained. The technology is used fairly commonly in the oil and gas industry, but it has never been installed at a commercial scale at a wind facility.

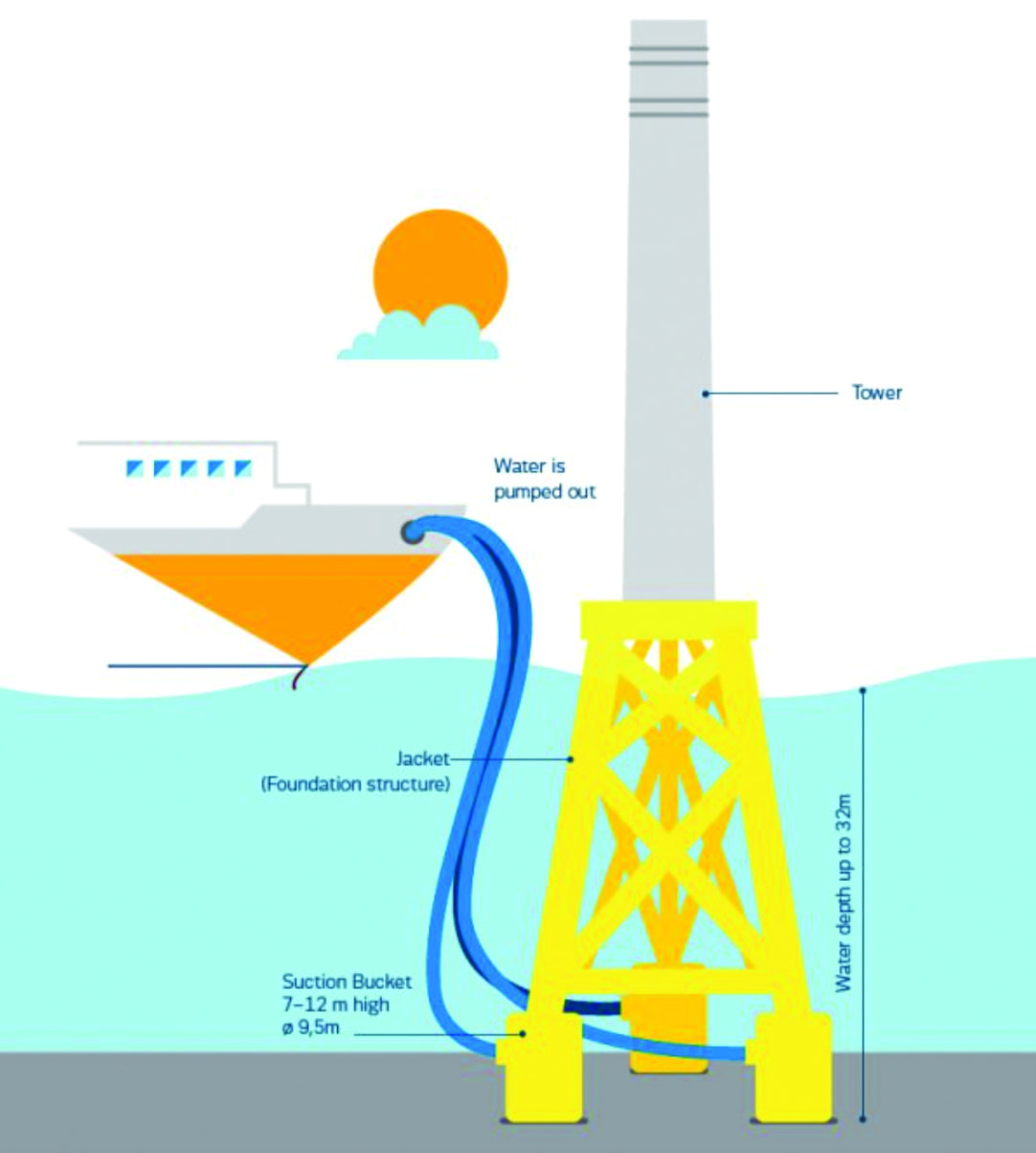

Installation of a suction bucket jacket foundation requires pumping water out of the buckets (Figure 5)—which are about 9 to 13 meters (m) high and have a diameter of 9.5 to 10.5 m—creating a pressure difference that essentially forces it onto the seabed. “In principle, pile drivers are replaced by water pumps,” Vattenfall said.

|

| 5. Suck and sink. As water is pumped out of the suction buckets, they sink into the seabed sediment. When the structures are decommissioned, water is pumped back in. Courtesy: Vattenfall |

“We believe that suction buckets may give us better options as the industry moves towards deeper water and larger turbines. The technology is especially suited where the soil conditions are not suitable for monopiles and it could open up new areas for offshore wind,” said Adam Ezzamel, project leader at the EOWDC in Aberdeen Bay (Figure 6). “By enabling faster and smarter installation, the technology will drive down offshore wind costs considerably, provide a further foundation option at challenging sites, whilst also allowing an easier and complete decommissioning.”

Ezzamel noted that seabed conditions and water depths of between 19 to 32 m at the test and demonstration facility are ideal for the foundation concept. When completed in September 2018, the facility will have a total capacity of 92.4 MW.

The foundations will hold up V164-8.4MW turbines manufactured by MHI Vestas, which will also be pioneered at EOWDC. MHI Vestas, which says the turbines are the most powerful in the world, noted that the turbine model has an optimized rotor-to-generator ratio. Additionally, the facility will feature a high-voltage 66-kV interarray and export cabling. Conventionally, wind farms use 33-kV installations, and the advancement is expected to reduce power losses and installation costs, as well as result in “significant copper savings,” Ezzamel said.

The savings are essential for Vattenfall, which wants to make offshore wind widely competitive. The company on March 19 announced it had successfully submitted a subsidy-free bid for a separate project, the 700-MW to 750-MW Hollandse Kust Zuid offshore wind farm in the Netherlands, though it did not specify the technology it will use at that project. Under Dutch tender rules, which were amended last year to allow zero-subsidy bids, the project would need to come online by 2023. That would mean it will likely come online before three subsidy-free offshore wind projects proposed in German waters—a total 1.4 GW—which are expected to begin producing power between 2024 and 2025. Those projects were awarded licenses in Germany’s first competitive offshore wind auction in April 2017. They include EnBW’s 900-MW He Dreiht wind farm in the North Sea, and Ørsted’s 240-MW OWP West and 240-MW Borkum Riffgrund West 2. (For more, see “Offshore Wind Has Taken Off in Europe” in this issue.)

According to Gunnar Groebler, Vattenfall’s senior vice president of Business Area Wind, the bid for the 356-square-kilometer (km) Hollandse Kust Zuid project, which will be sited 22.2 km off the Dutch west coast, resulted from “continuous cost reduction efforts along our entire value chain and the solid track record and portfolio approach of our company.” Vattenfall said it is now making final preparations for the project, including design of the wind farm along with internal planning and finalizing the tender process for major components.

—Sonal Patel is a POWER associate editor.