Successful Green Hydrogen Demonstration Project Is a Step Toward a Carbon-Free Future

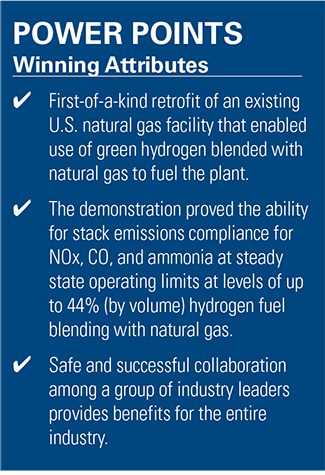

The New York Power Authority (NYPA) is leading the way in New York by piloting new technologies that can help accelerate the state’s clean energy transition. Among its accomplishments is a hydrogen demonstration project at its Brentwood site on Long Island, which was recognized with a POWER Top Plant Award.

It seems almost everywhere a person turns these days, someone is talking about hydrogen. In August, POWER and its sister publication, Chemical Engineering, hosted the HydrogeNext event, which is designed to help the power and chemical process industries understand the full hydrogen value chain, from production to distribution and end use. The event—part of Experience POWER Week and co-located with Electric Power Insights and the Distributed Energy Conference—brought professionals together to collaborate and learn about the fast-paced advances being made toward a hydrogen economy.

Among attendees at the event in Savannah, Georgia, were representatives from the New York Power Authority (NYPA), the Electric Power Research Institute (EPRI), and GE Vernova’s Gas Power business. The groups were there to accept a 2023 POWER Top Plant Award for a green hydrogen demonstration project completed at NYPA’s Brentwood Power Station on Long Island in Suffolk County, New York.

NYPA led the first-of-its-kind project in collaboration with GE Vernova, EPRI, Sargent & Lundy, Fresh Meadow Power, and Airgas, an Air Liquide company. NYPA said the project was the first retrofit of an existing U.S. natural gas facility to operate on a blend of green hydrogen to power the plant and generate electricity. NYPA and its industry collaborators demonstrated that the plant was fully operational while safely using the hydrogen blend. It said the project “informs New York and the power industry by demonstrating that hydrogen may be one valuable tool to help decarbonize power generation.”

A Suitable Site for Testing

The Brentwood site has a GE LM6000 PC gas turbine, which was commissioned in 2001 and utilizes a single annular combustor (SAC) combustion system. Over the past 20+ years, GE has made incremental reliability and performance improvements to the LM6000, and the company continues to sell this engine configuration for new unit installations today. All test results from the NYPA demonstration are also applicable to new LM6000 gas turbines with similar combustion configurations (Figure 1).

|

|

1. With more than 1,300 units shipped and more than 40 million operating hours, GE Vernova’s LM6000 aeroderivative gas turbine is a well-proven machine. It is reported to have greater than 99% start and operational reliability, and greater than 98% availability. Its five-minute fast-start capability and high cyclic life make it a great solution for complementing renewables or providing peak power. Courtesy: GE Vernova |

The effort to study renewable hydrogen in this application was part of New York’s comprehensive decarbonization strategy as outlined in the state’s nation-leading Climate Leadership and Community Protection Act. “The Power Authority is leading the way in New York by piloting new technologies that can help accelerate New York state’s clean energy transition and inform the power industry so that we can move toward a carbon-free economy,” NYPA President and CEO Justin E. Driscoll said in a statement when the results were announced. “Decarbonizing the power sector will require a collaborative, multi-pronged approach, including the use of new technologies and additional renewable power resources. NYPA is pleased to share the results of our hydrogen study with the industry and the public so that our key learnings can help illuminate future decarbonization efforts.”

The Brentwood site was chosen by NYPA because it is a single-unit site in a relatively remote location. The plant’s location and layout, combined with its relatively low capacity factor as a peaking unit, facilitated the temporary modifications required for the demonstration project. In addition to having the technology of interest for testing, the Brentwood plant also had the space and logistic support needed for hydrogen delivery and storage while testing.

The Fuel Blend and Results

The fuel blending ranged from 5% to 44% (by volume) hydrogen. The blend range was based on a recommendation by GE and was chosen based on several factors, including the capability of the engine at the site, the amount of hydrogen available, and site conditions.

With increased hydrogen blends, gas turbine NOx emissions for diffusion-style combustors, such as those at the Brentwood site, may be higher compared to natural gas because hydrogen’s adiabatic flame temperature is higher. However, the use of abatement technologies including water injection and the use of post-combustion after-treatment, such as selective catalytic reduction (SCR), were able to reduce plant NOx emissions.

The NOx emissions limit at the Brentwood site is 2.5 parts per million (ppm) at the stack. NYPA was able to get emissions permit exceptions for the purpose of the demonstration. Nonetheless, the team was able to maintain emissions within current permit levels during the testing thanks to the LM6000’s SAC water injected combustor and SCR system.

The short- and long-range impacts of higher hydrogen blends on the engine are a topic of current research. Results to date have been positive showing little durability and maintenance impacts based on laboratory analysis and short-term field testing. While the demonstration did not evaluate the effects of hydrogen on the engine and engine package components and materials, GE Vernova felt comfortable operating the LM6000 on hydrogen blends based on the extensive fleet experience of its current portfolio of aeroderivative and heavy-duty gas turbines operating on fuels with hydrogen content above 50% (by volume) and, in one case, with fuels that contain up to 94% (by volume) hydrogen. For future tests using higher hydrogen blends, sites may need to upgrade SCR systems and/or water injection systems to allow for higher water flows in order to maintain stack emissions similar to those obtained when firing on natural gas.

Overall, the gas turbine output, heat rate, NOx emissions, and CO2 reduction were in line with GE Vernova’s expectations. At 47 MW gross, CO2 mass emission rates were reduced by approximately 14% at 35% hydrogen cofiring, following the expected curve. With fixed water injection rates, NOx levels increased by 24% and CO levels decreased as the hydrogen fuel blend was increased, however, the NO2/NOx fraction decreased. Additional water injection was proven to maintain NOx emissions while maintaining and even reducing CO. This is a positive benefit in the impact on the efficiency and performance of some SCR catalyst formulations.

The demonstration proved the ability for stack emissions compliance for NOx, CO, and ammonia at steady state operating limits at the highest levels of hydrogen fuel blending (44% by volume). The reduction in CO emissions was about 85% versus natural gas, which was better than expected.

Fuel and Safety Challenges

From GE Vernova’s perspective, hydrogen availability and delivery were the largest challenges, as the amount of hydrogen required for the testing ended up being more than expected. For the demostration, about 1.3 million standard cubic feet of green hydrogen was used. If condensed to a liquid, that would be equivalent to about 11,680 gallons. It took the team a lot of planning and excellent on-site execution to align hydrogen availability with continuity of tests, resources, and data collection.

“The tremendous amount of hydrogen required was a challenge. This was overcome by spreading the test over a longer period of time so the hydrogen trucks could be replenished. In addition, the test was taking us into the unknown. There was no previous demonstration to refer to,” Alan Ettlinger, NYPA’s senior director of Research, Technology Development, and Innovation, told POWER.

“With several key collaborating companies on this project, it was important to align on our approaches and overcome any integration challenges during the early planning process,” Bobby Noble, EPRI’s program manager, said.

Running on hydrogen always comes with potential safety concerns. However, GE Vernova said design and plant-level hazardous assessment reviews identified all safety concerns, which were then addressed through equipment upgrades, re-calibrations, personnel training, and updated environmental, health, and safety (EHS) practices.

NYPA said the project followed New York state’s building and energy code, and all National Fire Protection Association (NFPA) requirements. Program managers also kept in close contact with the New York State Department of Environmental Conservation and local emergency services. “Every morning on testing days, all personnel were gathered to provide a safety brief and the Plan of the Day to ensure all personnel were briefed on the day’s events and protocols to follow,” said Tim Zandes, senior advisor of Asset Strategy with NYPA.

“The large number of teams involved were able to produce a design approach to ensure that all the safety and operational requirements were met,” Noble added.

Tasks, Findings, and Next Steps

Concerning the team and each group’s responsibilities, NYPA led the project, as previously noted. GE Vernova assisted in the building of the state-of-the art hydrogen/natural gas blending system. EPRI’s Low-Carbon Resources Initiative helped design the project and served as advisors on the technical evaluation. Airgas supplied the renewable green hydrogen for the testing. Sargent & Lundy was the original architect engineer of the Brentwood plant and provided engineering expertise as well as safety reviews. And last, but not least, Fresh Meadow Power developed the piping system that delivered the hydrogen to the GE-designed mixing skid and, ultimately, into the turbine.

According to NYPA, this cutting-edge research provides critical insights into the potential for blending clean hydrogen and natural gas, which is one potential use among many for clean hydrogen. This data provides more information to support continued discussions about the future of clean hydrogen that will leverage New York’s commitment to achieving a zero-emissions electric grid and the area’s unique geographies and abundant renewable resources.

GE Vernova is continuing to conduct testing in its combustion laboratory to expand the capability of SAC combustion systems with a goal of allowing emissions-compliant gas turbine operation on 100% hydrogen in the near term. In addition, GE Vernova is also developing next-generation DLE (dry low emissions) combustion technology to operate on 100% hydrogen without the need of water injection for NOx control.

—Aaron Larson is POWER’s executive editor.