Global demand for power is increasing. In order to meet that demand, we need fast, dependable options. Battery energy storage systems (BESS) are the fastest path to new capacity, thanks to their agile deployment and ability to support flexible interconnections.

These advantages, among others, have positioned storage as the most immediate solution to meeting growing global energy demand while also addressing the reliability requirements of large loads. That said, battery storage is only as good as its uptime, and ensuring that BESS is available when it matters most comes down to its software controls.

COMMENTARY

Battery software is also becoming increasingly important as the power landscape becomes more dynamic. Early BESS applications were primarily focused on single-value use cases, such as peak shaving and energy arbitrage. Now, evolving grid conditions and new large loads, such as for artificial intelligence and data centers, are giving rise to more complex and flexible battery storage operations, where advanced software must orchestrate various grid services and behind-the-meter load management needs. Hybrid sites, like solar-plus-storage, are also on the rise, and can benefit from advanced software to control and co-optimize multiple assets, reducing complexity and costs.

All of that is to say: battery storage isn’t the solution on its own. Power producers and large-load customers need storage paired with a modern energy management system (EMS) to deliver reliable capacity, serve dynamic AI-driven loads, and protect project economics.

Back to the Basics: Why the Right EMS Software Matters

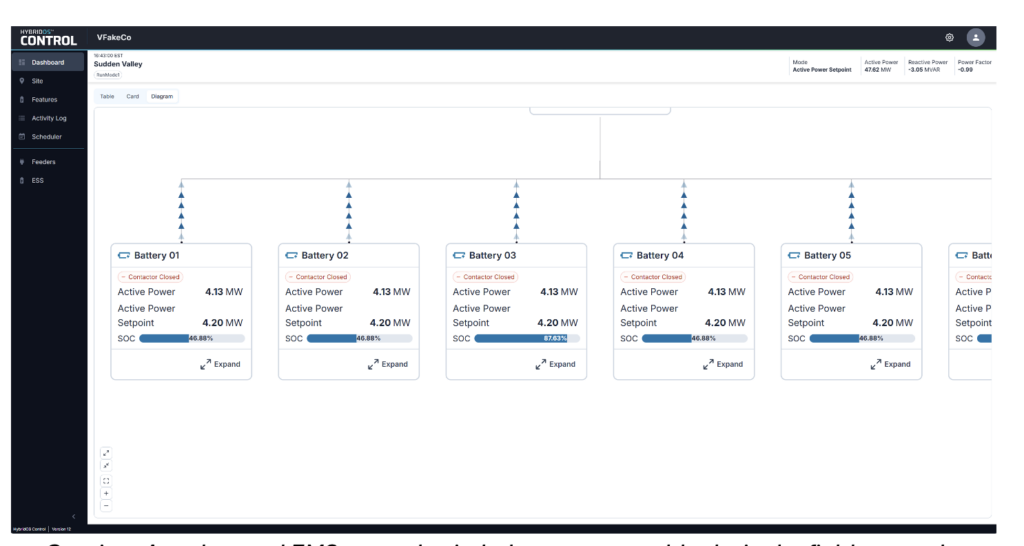

The EMS is the control layer that optimizes battery storage and other energy assets, ensuring the grid or customer gets the right services at the right times and that operators capture the most revenue opportunity. An EMS acts as the brain behind the battery, overseeing and communicating with all subsystems to dictate how and when to store or dispatch energy, respond in real-time to market demands, and share predictive analytics to maximize asset life. The EMS is a small portion of a project budget, yet choosing the right software plays an outsized role in a project’s return on investment (ROI).

To see why, let’s look at a hot summer day: two identical battery sites face the same grid conditions, but one runs on a bare-bones EMS and the other on a high-performance platform.

Mid-afternoon, the transmission operator calls to say your site is delivering 90 MW instead of its contracted 100 MW. With a basic EMS, the operator is stuck sifting through raw data, trying to isolate the issue while the clock is ticking on the highest-value hours of the year. After finally diagnosing the issue, a technician is dispatched to the site, and the project continues to incur lost revenue and potential penalties until the problem is resolved.

With a high-performance EMS, the same fault looks very different. The software continuously benchmarks expected versus actual performance, detects the deviation immediately, and quickly isolates a root cause. In many cases, it resolves the issue remotely or guides a fix before output drops far enough to trigger an operator call. Additionally, with fleet-level dashboards, real-time alerts, and site-specific controls, operators can keep availability high across dozens of projects to maximize revenue during the times it matters most.

Battery Availability is the Real Asset

That contrast between a reactive scramble and proactive control highlights how project value depends on battery availability, and the EMS is what ensures it. The best way for battery storage operators to protect their revenue is by minimizing unplanned downtime and ensuring that planned downtime, such as maintenance, doesn’t coincide with high-earning events. An advanced EMS supports this strategy in a few key ways.

First, preventative maintenance. Delays in maintenance can cause accelerated battery degradation, so an EMS that proactively identifies maintenance needs and optimizes maintenance schedules will keep batteries running at a high level for longer.

Second, rapid issue detection, so problems don’t escalate. An advanced EMS supports faster fault recovery and helps identify and resolve issues quickly, allowing a site to get back online and generate revenue. An EMS coupled with remote monitoring also provides operators with real-time updates on site performance, so that high-earning events are never missed.

And finally, proactive battery health insights. Advanced EMS functionality can also unlock more precise state-of-health diagnostics based on actual site conditions, rather than generic projections, so asset managers can more accurately plan for augmentation timelines and implement strategies that extend battery life.

The EMS Protects and Grows Storage ROI

ROI from battery storage is won by avoiding downtime and capturing market opportunities. Your revenue model assumes the system will deliver contracted output when called, pass performance tests, and respond within required timelines. A bare-bones EMS puts that at risk: faults take longer to diagnose, dispatch targets can be missed, and operators are forced into manual workarounds, like in the summer day scenario. The result is money left on the table because of under-delivery or penalties, plus the longer-term cost of losing trust with grid operators and offtakers. A high-performance EMS protects ROI by ensuring the asset reliably delivers on its commitments.

On the other hand, capturing upside hinges on being available during the few extreme peak events, such as summer heatwaves and winter cold snaps, that put the most stress on the grid, require the most agility, and drive a large share of annual earnings. If a battery is down in those windows, there’s a significant hit to yearly revenue. Advanced EMS controls keep systems healthy, schedule maintenance away from peak risk, and catch issues early so the project earns when it matters most.

In the long term, ROI also depends on staying adaptive over an asset’s lifespan, as market and grid priorities evolve, regulations change, and value streams shift. The EMS is how storage keeps up without expensive retrofits or constant retuning. ERCOT is a good example: grid service economics have moved quickly, rewarding operators who can update participation strategies in response. Or in Europe, where new markets are emerging while others become saturated, leading project owners to diversify their revenue streams. The right EMS doesn’t just improve performance today; it future-proofs profitability and supports scale over time.

Software Will Define the Next Phase of American Energy

As electricity demand rises, the grid needs highly available and reliable BESS that can come online quickly to meet demand challenges. Software optimizes batteries to meet these grid needs.

Operators that implement an advanced EMS, whether in new projects or retroactively in existing projects, and who work with hardware-agnostic EMS providers will see benefits: availability when it matters most, reduced downtime, preventative maintenance and predictive insights, and flexibility to meet evolving power needs. All of that translates to more revenue for owners, better support for large-load customers, and improved service to the grid as demand rises.

Historically, much of the power sector has been defined by physical infrastructure and steel in the ground, but now, the future of the power sector will be defined by advanced software to solve our biggest energy challenges.

—Hugh Scott is chief technology officer at FlexGen.

- Federal Power Act

- emergency orders

- baseload generation

- coal-fired power plants

- reliability must run

- power plant closures

- DOE

- Section 202(c)

- federal intervention

- utilities

- ratepayer costs

- grid reliability

- WECC

- energy policy

- MISO

- electric cooperatives

- resource adequacy

- power markets

- coal plant retirements

- electricity reliability