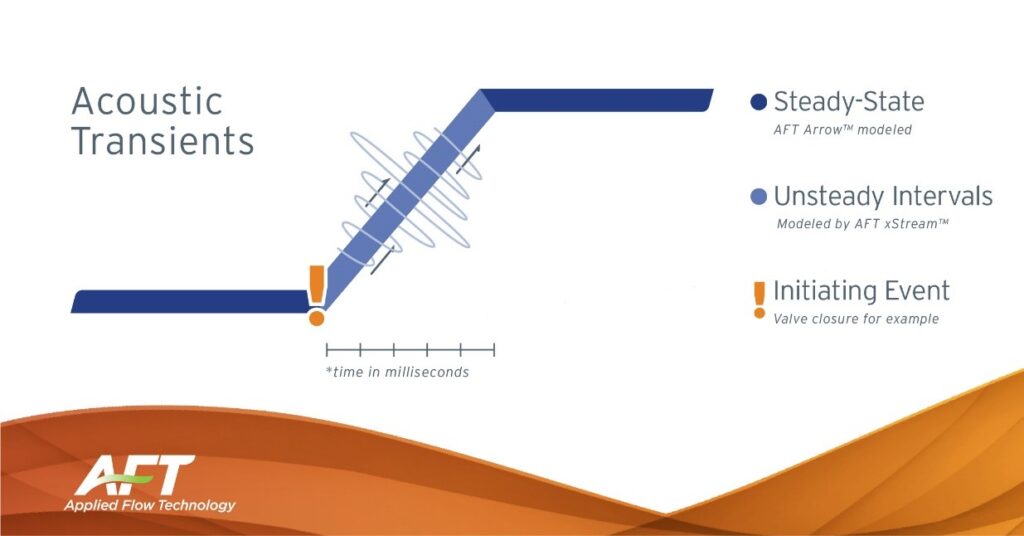

Engineering gas and steam piping systems within power generation facilities is a tough job. Balancing cost, effectiveness, and safety while anticipating changes to design requirements takes a lot of work. Analyzing the gas dynamics of a piping system often occurs exclusively at steady-state, but transient deviations from steady-state should face similar scrutiny in the design process.

Transient events create a cascade of effects on a piping system. A change in operating point could create unacceptable pressure spikes or vacuums, cause damage to fragile equipment, and in many cases create hazardous conditions or costly downtime.

Engineers using AFT xStream can determine, analyze, and mitigate the effects of harmful transient events by seeing how their system will react, preventing problems before they happen.

Despite potentially harmful transient events lurking in every piping system, transient analysis is often overlooked in the design process. Transient analysis takes significant time to explore what might happen and is often its own engineering discipline. Transient analysis of compressible flow is even more limited due to compressible fluid’s increased complexity.

Rather than perform a transient analysis, engineers might rely on excessively conservative (and therefore excessively expensive) design margins for their systems. Even worse, engineers may cross their fingers and hope these risky events never occur, and only investigating after a problem occurs.

This begs the questions:

- How do you know how your system will react to a transient?

- Are the mitigation strategies in place effective?

- Is your system safe during its worst-case scenario?

It’s time to stop the guessing games and address the compressible transient events of your system through software tools that make transient analysis flexible, intuitive, and efficient.

What is a compressible transient?

A compressible transient describes time-dependent deviations from standard steady-state operation of a gas or steam system where compressibility effects are significant. These compressible transient events include:

- Blowdowns and depressurization studies

- Turbine trip and start-up events

- Emergency shutdowns

- Relief/safety valve operation

Often these compressible transient events cannot be avoided, creating costly or dangerous concerns. These events require engineers to anticipate and develop mitigation strategies accordingly. However, this valuable transient analysis is often overlooked in the engineering design process because it has historically been difficult to perform.

Why is it difficult to analyze compressible transients?

For gases and steam, complex equations of state considering pressure, temperature, volume, and compressibility inform how a fluid flows in a pipe. Pressure losses, heat transfer, and sonic choking also impact the fluid’s flow.

Each of these factors can change with time during a compressible transient, which is a tall order for even the most experienced engineers. Since internal compressible transient tools are difficult to develop, the peace of mind to address transient concerns might instead come at the cost of excessively conservative design.

Luckily, a tool like AFT xStream captures these complexities for engineers, allowing them to focus on troubleshooting their system instead of troubleshooting their analysis tool. This enables engineers to refine their designs and cut cost with confidence.

What does compressible transient analysis look like?

Since ‘compressible transients’ encompass all deviations from steady-state operation, the analysis of different systems and their corresponding transient events can vary significantly.

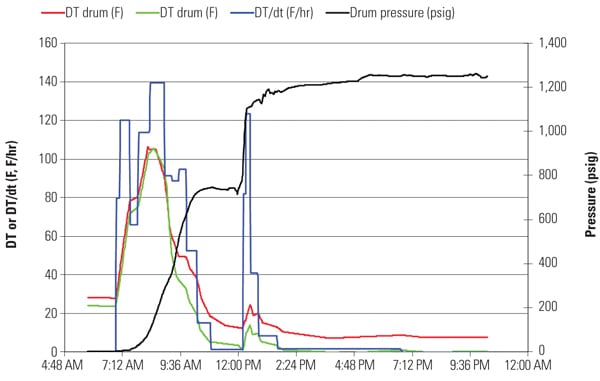

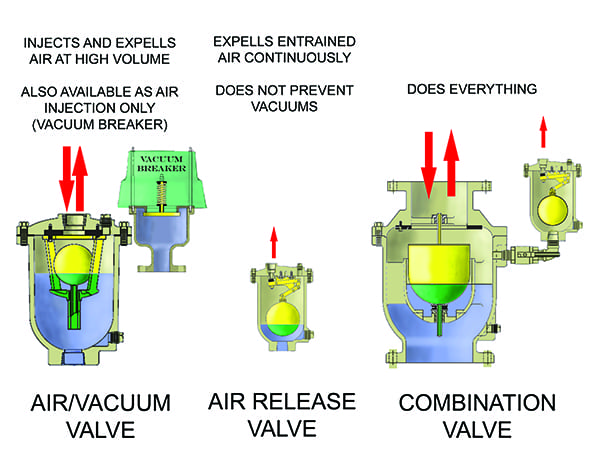

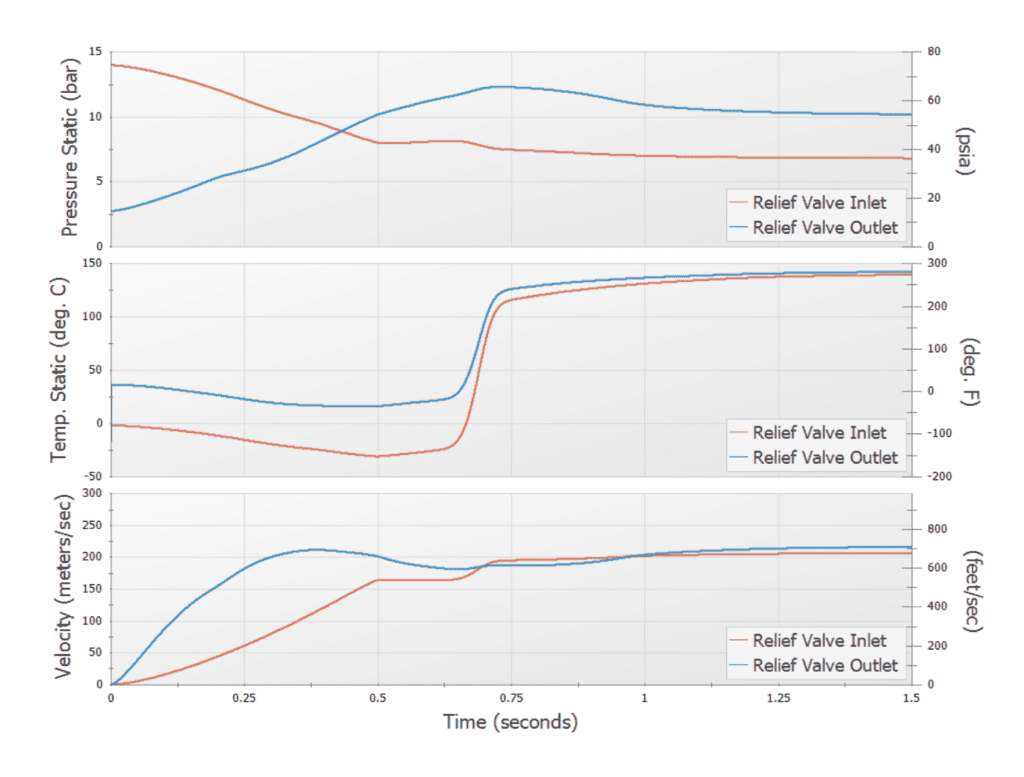

Safety Valve Analysis: Analyzing a safety valve system could explore the peak relief capacity and determine the time it takes to mitigate an overpressure event. A model could also determine the impact of a relief event on the larger piping system and complementary relief systems. The sudden pressure difference across a relief valve will also create significant forces, which can be analyzed in software and exported for pipe stress analysis.

Turbine Analysis: When analyzing gas or steam turbines, an engineer might explore disruptions in supply to ensure continuous turbine operation. Engineers could determine start-up and shut-down procedures to ensure smooth operation and confirm pressure rises are within the turbine’s tolerance. Turbine downtime is a costly headache that can be prevented with compressible transient analysis.

Pipeline Analysis: Gas pipelines face separate challenges to avoid service disruptions from compressible transients. Engineers might consider overpressure impacts like line pack from valve closures. Daily changes or long-term increases in consumer demand impact operating procedures, which engineers can plan for. Safety is also a significant consideration for gas pipelines, so depressurization studies or isolation cases due to blockage would also inform engineering decisions.

These systems and more benefit from precautionary transient analysis, anticipating and mitigating issues before they occur.

How does an engineer perform compressible transient analysis?

While the relevant analysis for engineers differs across systems and their corresponding transients, many of the approaches and tools to analyze these events are the same.

Transient analysis results in millions of data points for engineers to sift through. Software tools like AFT xStream rely on graphing and animation features for engineers to visualize their system’s response, isolating the relevant information to fundamentally understand the transient event. This makes system interactions between pressure, temperature, and velocity intuitive and approachable. Fundamentally understanding a system’s response allows engineers to either mitigate the cause of a transient or adequately address its effects.

This analysis can be expanded to a range of operating conditions, allowing engineers to consider what-ifs and design alternatives gracefully in a single file. Tools that enable intuitive analysis let engineers follow their curiosity and discover solutions for better, safer, and more reliable designs.

Compressible transient analysis has long been limited by high-cost, difficult-to-use, and esoteric analysis tools. Applied Flow Technology’s foray into the field has been long anticipated and builds upon AFT’s 27-year history of pipe flow modeling. Stop the guessing games and trust your compressible transient analysis to AFT xStream.

Want to talk to learn more about Compressible Transient Event Modeling, xSTream, or AFT? Fill out the form below and we’ll be in touch.