Two much-watched advanced nuclear fuel technology companies—Oklo and Lightbridge—will consider co-locating their commercial metallic fuel fabrication facilities to explore synergies and potentially accelerate innovation across the nuclear supply chain.

Under a Jan. 28–announced memorandum of understanding (MOU), the companies plan to conduct a feasibility study that will explore co-locating a Lightbridge Commercial-scale Fuel Fabrication Facility at Oklo’s proposed commercial fuel fabrication facility. The effort will also explore advanced fuel recycling opportunities.

“The potential co-location of our commercial fuel fabrication facilities could offer significant synergies in terms of upfront capital expenditures and ongoing operating costs,” said Lightbridge President and CEO Seth Grae. “Furthermore, exploring advanced fuel recycling opportunities with Oklo aligns perfectly with our commitment to sustainable nuclear energy solutions.”

The companies did not disclose a potential site for the co-located fabrication facilities, and Oklo confirmed it has not yet finalized a site for its planned commercial fresh uranium fuel fabrication facility. However, Lightbridge and Oklo, notably, have each separately explored Centrus Energy’s American Centrifuge Plant in Piketon, Ohio—where Centrus is producing high-assay, low-enriched uranium (HALEU) under a demonstration project.

Lightbridge last year set out to conduct a front-end engineering and design (FEED) study, led by Centrus, to add a dedicated Lightbridge Pilot Fuel Fabrication Facility (LPFFF) at the site, working to identify infrastructure and licensing requirements and an estimated cost and construction schedule. In 2023, Centrus and Oklo partnered to explore developing a comprehensive HALEU fuel cycle, including producing, deconverting, and fabricating advanced nuclear fuel for Oklo’s Aurora reactors while also making Centrus a potential power off-taker for Oklo’s planned microreactors in Southern Ohio.

A High-Stakes Fuel Alignment

The partnership marks another notable example of collaboration within the advanced nuclear sector as part of an urgent bid to secure a reliable supply chain, including for advanced nuclear fuel and related materials. In November, DeepGEO, a multinational spent nuclear fuel (SNF) repository developer, and Danish thorium reactor developer Copenhagen Atomics moved to align waste management solutions with next-generation reactor technologies.

At the core of the problem is that the U.S. nuclear fuel fabrication industry has seen little change in decades, and it largely remains rooted in a legacy designed to support light water reactors (LWRs). Today, fuel for the nation’s 95 commercial reactors is largely fabricated by industry heavyweights like Westinghouse, Global Nuclear Fuels (GNF), and Framatome, which primarily produce uranium dioxide (UO₂) ceramic pellet fuel with enrichments below 5% U-235, categorized as Category III material. The pellets are typically stacked into zircaloy tubes, assembled into fuel bundles, and shipped to power plants. While modernization has resulted in efforts to produce slightly higher enriched LEU+ fuel, and specialty facilities have emerged to supply advanced fuels for research reactors and naval propulsion, large-scale fabrication of advanced fuels remains elusive.

Burgeoning prospects for advanced nuclear reactors have introduced bold new demands on the fuel supply chain. Unlike traditional LWRs, many advanced reactors require higher enrichments (up to 19.75% U-235, Category II material) and innovative fuel forms, including metallic fuels, TRISO particle fuel, and molten salts. These fuels often involve intricate geometries, specialized coatings, and unique chemical processes, necessitating entirely new fabrication methods and infrastructure. With no commercial-scale infrastructure yet in place, advanced fuel fabrication faces steep challenges. Scaling up from pilot operations to full production will require significant investments in licensing, safety systems, material safeguards, and regulatory oversight. A lack of standardization in advanced fuel types also presents economic and technical hurdles. Industry has suggested multiple small-scale facilities will likely needed to accommodate diverse reactor designs until the market converges on preferred technologies.

Advanced Fuel Alignment: Lightbridge’s Progress

Lightbridge, founded in 1992 as Thorium Power, has transitioned from its early focus on thorium-based nuclear fuel technologies to become a pioneering developer of advanced metallic fuel for nuclear reactors. Its flagship product, Lightbridge Fuel, incorporates a patented design consisting of extruded metallic rods made of a zirconium-uranium alloy matrix within zirconium alloy cladding.

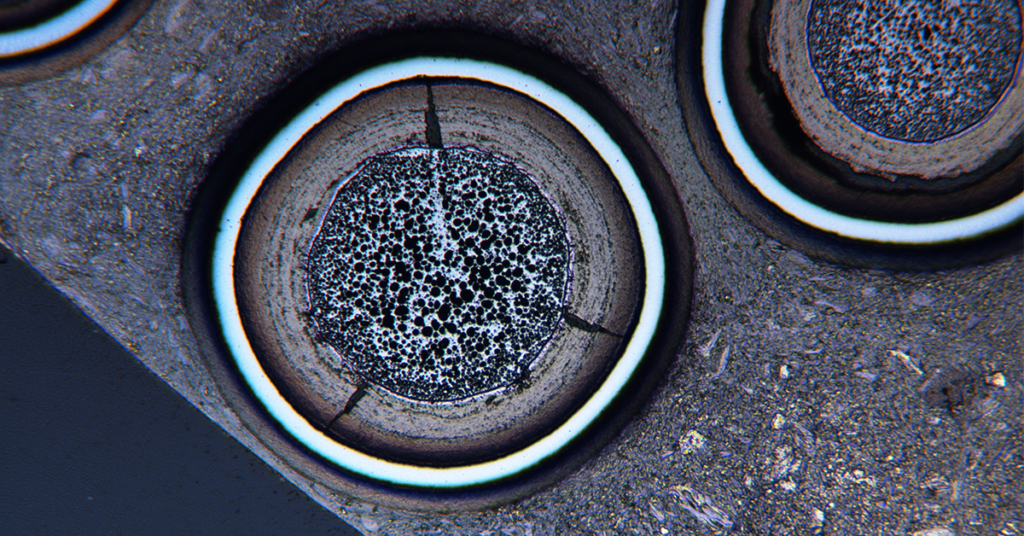

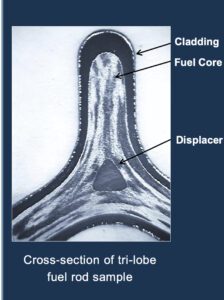

Compared to traditional ceramic pellet-in-tube designs, Lightbridge’s multi-lobed and helically twisted rod structure (inspired by decades of successful use of uranium-zirconium alloy fuel in nuclear-powered icebreaker ships) is designed to increase the surface area for heat transfer, allowing the fuel to run cooler and more efficiently, and the absence of a fuel-cladding gap further enhances safety by reducing mechanical failure risks and ensuring better thermal conductivity.

The alloy composition—approximately 50% uranium and 50% zirconium by weight—reduces the production of plutonium and other long-lived transuranics, but it can also use enrichments up to 19.75 wt% U-235—high assay low enriched uranium (HALEU)—“which has sufficient fissile material to support reaching high burnups and to enable power-uprates and cycle-length extensions,” the company says. A remarkable advantage of the fuel is that it is “expected to enhance the safety, economics, and proliferation resistance of nuclear fuel by operating about 1000C cooler than standard fuel, enabling power uprates and extended cycle lengths, and producing less plutonium than standard fuel,” the company says. In addition, the fuel is designed to work in both new and existing reactors.

So far, Lightbridge has made significant strides in refining its fabrication process for the innovative metallic fuel design. In March 2024, Idaho National Laboratory (INL) demonstrated the extrusion process for Lightbridge Fuel material composed of a depleted uranium-zirconium alloy. The crucial fabrication process involved casting ingots, assembling billets with central displacer materials, and co-extruding them through a specialized die to create helically twisted, multi-lobed metallic fuel rods.

Lightbridge continues working with INL and the U.S. Department of Energy on irradiation experiments in the Advanced Test Reactor (ATR) and Transient Reactor Test (TREAT) facilities to generate performance data for regulatory licensing. Additional research includes a study with the Romanian Institute for Nuclear Research to explore the potential use of Lightbridge Fuel in CANDU reactors. The company is also collaborating with Texas A&M University and MIT to examine the fuel’s application in small modular reactors, including the NuScale VOYGR design.

According to CEO Grae, Lightbridge Fuel, for now, is positioned at a technology readiness level (TRL) of 4–5. “At this stage, Lightbridge Fuel has moved beyond theoretical research (TRL 1-3) and entered into the realm of validation in a laboratory environment (TRL 4) and initiation of validation in representative operating conditions (TRL 5),” he noted in a February 2024 letter to shareholders. “Achieving TRL 4-5 is an important milestone which validates the Lightbridge Fuel design thus far and sets the stage for subsequent development steps, moving us closer to commercialization and widespread adoption of our advanced nuclear fuel (TRL 8-9).” Over the next three years, Lightbridge will seek to advance its technology into the later stages of validation, with an emphasis on scaling up fabrication processes, expanding experimental testing, and generating regulatory data to pave the way for licensing and market entry, he said.

Oklo Exploring Fabrication in Tandem With Recycling

Oklo, founded in 2013, is meanwhile developing a suite of nuclear solutions under a “full value chain” approach that involves managing smaller reactors’ design, build, and operation through power purchase agreements (PPAs). It is targeting the first deployment of its flagship offering, the 15-MWe–100 MWe Aurora powerhouse—a compact passive fast-spectrum reactor—at Idaho National Laboratory (INL) by 2027. The company has already secured a customer pipeline of 2.1 GW, including agreements with major data center operators. In December, it partnered with Switch, a Las Vegas-based data center designer, builder, and operator, to deploy 12 GW of Aurora powerhouses through 2044 in a historic deal hailed as “one of the largest corporate clean power agreements ever signed.”

The company’s liquid metal-cooled, metal-fueled fast reactors will rely on advanced metallic fuel based on HALEU. Five metric tons of HALEU for Oklo’s first commercial powerhouse will be sourced from the former EBR-II reactor and fabricated at its Aurora Fuel Fabrication Facility at INL, a project currently under development. Pre-application activities for the facility began with the Nuclear Regulatory Commission (NRC) in 2023, and the DOE approved its conceptual design in October 2024.

In addition, Oklo is planning a commercial fresh uranium fuel fabrication facility to support its broader deployment goals. The planned facility is expected to play a pivotal role in scaling up fuel production to meet the needs of Oklo’s growing reactor fleet, including its 15-MWe and 100-MWe Aurora designs.

Separately, Oklo is also trailblazing in fuel recycling, seeking to convert SNF from LWRs (which is in the form of ceramic oxide) to usable metallic HALEU fuel. In July 2024, the company achieved a significant milestone by completing an end-to-end demonstration of its pyroprocessing technology in collaboration with Argonne National Laboratory and Idaho National Laboratory. This process involves separating valuable elements like uranium and transuranic materials through electrorefining in a molten salt environment. Oklo in Nov. 2024 moved to acquire Atomic Alchemy, a U.S. firm specializing in high-value radioisotopes, in a $25 million all-stock transaction.

Oklo is developing a commercial recycling facility targeted for the 2030s. While a specific site has not yet been announced, Oklo is actively collaborating with the NRC on aspects of the license application.

“Collaborating with Lightbridge represents a unique opportunity to accelerate innovation across the nuclear supply chain,” said Jacob DeWitte, co-founder and CEO of Oklo. “The potential to co-locate facilities and collaborate on cutting-edge technologies is aligned with our commitment to delivering cost-effective, carbon-free energy solutions. Together, we are exploring new frontiers in nuclear fuel development and recycling to ensure a cleaner and more sustainable energy future.”

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).