INL Achieves Fabrication of Commercial-Grade Specialized Nuclear Fuel Pellets

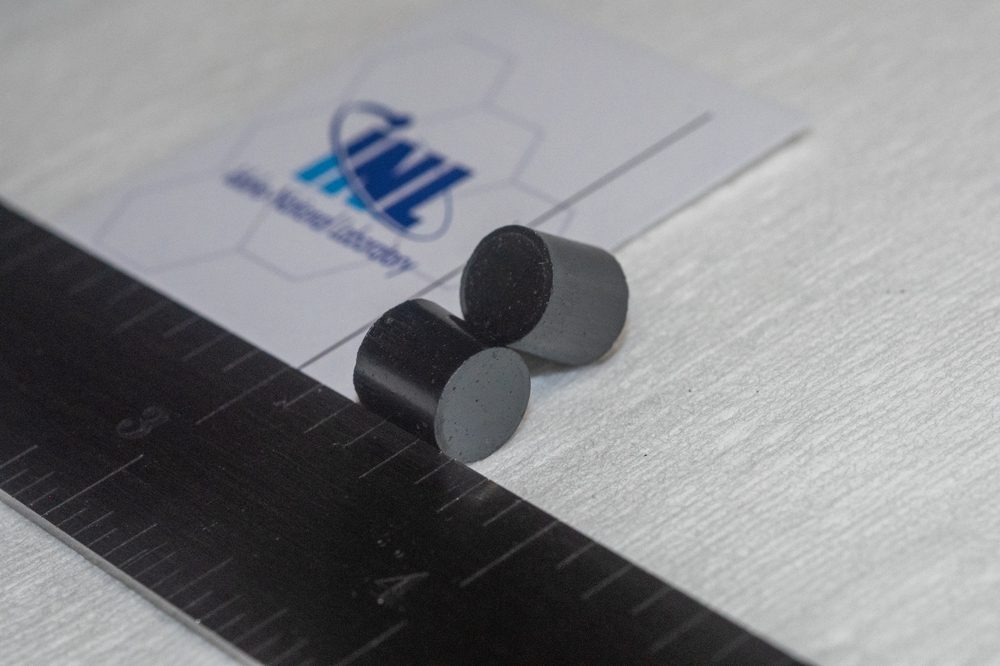

Idaho National Laboratory (INL) has fabricated roughly two dozen commercial-grade fuel pellets of high-assay low-enriched uranium (HALEU) uranium dioxide (UO2), the Department of Energy (DOE) revealed on Nov. 20. The milestone demonstrates the national laboratory’s “unique ability” to provide customized nuclear fuel for industry and government partners, the DOE said.

INL said researchers at the Experimental Fuels Facility at the Material and Fuels Complex in Idaho fabricated about two dozen pellets of UO2 HALEU in “early 2023.” The specialized pellets contain fuel enriched to 15% uranium-235.

While conventional light water reactor (LWR) fuels are typically enriched to less than 5% uranium-235—a limit allowed by most existing Nuclear Regulatory Commission (NRC) operating licenses—HALEU enrichment needs ranges of between 5% and 19.75%. Because HALEU is enriched higher, it may provide more power per volume than conventional reactors, and its efficiency allows for smaller plant sizes. The fuel type also promises longer core life and a higher burn-up rate of nuclear waste. Many advanced nuclear reactor designs, including nine of the 10 designs awarded under the DOE’s Advanced Reactor Demonstration Program (ARDP), require HALEU.

Another 100 to 150 Pellets Will Be Fabricated

INL fabricated its pellets using a traditional powder metallurgy process, “a pressure-less sintering technique similar to that used by industry to make light water reactor fuel,” it said. Researchers are now testing the fuel pellets to evaluate their properties and identify impurities.

Plans then call for the fabrication of another 100 to 150 pellets to support testing of a specialized cladding developed by General Electric’s Global Nuclear Fuels (GNF) in INL’s Advanced Test Reactor. The project, funded under the DOE’s Accident Tolerant Fuel Program, is expected to “improve the performance of existing light water reactors and future advanced reactors.”

But, according to INL, the milestone is more significant because demonstrating UO2 HALEU could pave the way for the development of other types of HALEU, including metallic and ceramic types. Testing fuel is an important precursor to obtaining NRC licensing, it noted.

“The pellets that we produced were extremely high density,” noted Jennifer Watkins, a nuclear fuels and materials scientist at INL, who led the project. “Our initial characterization efforts suggest they will meet all commercial standards for uranium dioxide.”

Firming Up the HALEU Supply Chain

The milestone also “highlights INL’s ability to tailor enrichments to customer and experiment requirements,” the lab said earlier this week. Demonstrating the capability to fabricate a commercial quality of HALEU UO2 “provides options for industry and other government agencies to make fuel samples with a wider range of enrichment without impacting existing operating licenses,” it added. The project’s success also “establishes INL as the go-to custom HALEU fuel fabricator for reactor companies,” it said.

INL’s announced achievement is the latest of a series of milestones in concerted efforts by the power industry and government to develop a HALEU supply chain. The DOE posits more than 40 metric tons of HALEU may be needed by 2030 to deploy a new fleet of advanced reactors in a timeframe that supports net-zero emissions targets by 2050.

Centrus Energy, a firm under a DOE contract to demonstrate production of HALEU with domestic technology, in October 2023 kicked off enrichment operations at its American Centrifuge Plant cascade in Piketon, Ohio—the nation’s only NRC-licensed HALEU facility. Earlier this month, the nuclear fuel and services firm delivered its first batch of HALEU uranium hexafluoride (UF6, 19.75% enriched) to the DOE.

That milestone marked the completion of the first phase of a multiphase agreement with the DOE awarded in November 2022. Phase 1 of the contract called for the completion of Centrus’s 16-centrifuge cascade and the start of operations to produce an initial 20 kilograms (kg) of HALEU UF6 (19.75% enriched) by December 31, 2023. Under Phase 2, Centrus plans to continue production for a full year at an annual production rate of 900 kg of HALEU.

Phase 1 included a 50% cost share requirement for Centrus, and the company and the DOE each contributed about $30 million of the $60 million overall cost. In Phase 2 of the contract, the DOE will pay Centrus on “a cost-plus incentive fee” basis for the HALEU the company produces. However, the DOE will own the HALEU produced from the demonstration cascade. The operation contract also gives the DOE options to pay for up to nine additional years beyond the base contract (though those options will be subject to the availability of Congressional appropriations).

However, Centrus is separately also exploring the possibility of scaling up the Piketon facility for expanded HALEU production. “The capacity of the 16-centrifuge cascade is modest—about 900 kg of HALEU per year—but with sufficient funding and offtake commitments, Centrus could significantly expand production,” the company noted. A full-scale HALEU cascade, comprising 120 centrifuge machines has a combined capacity to produce approximately 6,000 kg of HALEU per year (6 MTU/year). It “could be producing HALEU within 42 months after securing the necessary funding,” Centrus said. “With appropriate support, Centrus could add a second HALEU cascade six months later and subsequent cascades every two months after that.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).