O&M

-

O&M

Dissimilar-Metal Weld Is a Misnomer

Most combined cycle professionals understand that a joint between grade 91 steel and an austenitic stainless steel is considered a dissimilar-metal weld. For that reason, it requires special welding

-

O&M

Using Rotor-In Major Inspections to Shorten Outages and Drive Safety

Today, some F-class operators continue to opt for rotor-out major inspections, which are cumbersome and inefficient. They involve complex lifts and moves of the rotor, as well as the need for substantial space

-

Connected Plant

The Future Is Now: Connected Power Plants Are Here

New technology is being used throughout the power industry to improve plant efficiency, predict trouble with degrading equipment, forecast weather trends, and train workers. A recent conference hosted by POWER

-

O&M

Reducing Cycling Damage to Combined Cycle Steam Turbines

Cycling a combined cycle plant places additional stresses on all equipment, but the impacts extend beyond the gas turbine and heat recovery steam generator. Plant owners and managers are beginning to see

-

Connected Plant

Facilitating Predictive Maintenance of Electrical Assets with Pervasive Sensing Strategies

Continuous condition-based monitoring of electrical conductors and insulation is an effective way to reduce required plant maintenance activities, cut operating costs, and prevent unplanned shutdowns

-

O&M

Enhanced Boiler Defense Strategies for an Aging Coal Fleet

Cyclic operating conditions can be problematic for many coal-fired power plants that were designed to run as baseload units. Implementing a combustion and boiler performance management program can help ensure

-

O&M

Strategies for Small Hydro Upgrades

Small hydro is becoming big business as ongoing technological advances make more small sites economic to exploit. Older plants can also see substantial output and efficiency gains by upgrading from decades-old

-

O&M

Simplify Outage Planning to Increase Collaboration

Many elaborate planning tools are available to help managers prepare for power plant outages. However, there is something to be said for keeping things simple. One modest tool that some NRG Energy facilities

-

O&M

The Oft-Neglected Isolated Phase Bus Deserves Your Attention

A power plant’s isolated phase bus is generally reliable, and therefore, maintenance is frequently overlooked. However, the system is too important to neglect. Assessing its condition during minor outages

-

Connected Plant

Cybersecurity: Keeping Current on a Moving Target

What it means to have a secure energy generating facility has changed in recent years as the threat of cyberattacks grows. As the nation’s energy sector becomes increasingly interconnected, it is more

-

Legal & Regulatory

U.S. Nuclear: From Hope to Despair

A decade ago, the annual Platts nuclear energy conference in Washington was brimming with optimism over a coming “nuclear renaissance,” as licensing requests poured into the Nuclear Regulatory Commission

-

Commentary

Reports of the Electric Grid’s Death Have Been Greatly Exaggerated

There have been numerous pronouncements recently about the upcoming demise of the bulk power grid as consumers are projected to move toward decentralized green energy sources. We don’t believe that the end

-

IIOT Power

New Approaches for Transformer Operation and Maintenance

Technology advancements and new regulatory requirements could reshape how power plant owners operate and maintain large power transformers. Experts outline emerging strategies and call attention to overlooked

-

O&M

Who Has the World’s Most Efficient Coal Power Plant Fleet?

A comparison of coal power plant fleets from China, the European Union (EU), Japan, and the U.S. by the International Energy Agency’s (IEA’s) Clean Coal Centre yields surprising insights into efforts these

-

O&M

Eddy Current Tube Inspections Efficiently Find Defects

Eddy current testing is a well-established method of nondestructive testing that is used to examine nonferrous/nonmagnetic materials such as condenser and heat exchanger tubes in power generation plants. Eddy current testing reveals discontinuities in tubing, provides plant engineers with an accurate assessment of a unit’s condition, and is a tool for predicting the remaining useful […]

-

Connected Plant

Protecting Critical Infrastructure

Society is highly reliant on the safety and stability of critical infrastructure. From boiling a kettle to maintaining national security, an interruption in the electricity supply can cause serious damage to

-

O&M

Cooling Towers: Efficiency Waiting to Happen

Cooling towers serve the vital role of cooling water for power plant heat exchange equipment. Sustaining excellent system performance is important because a one-degree increase in water temperature can cause a 2% increase in energy usage. Proper maintenance and a few upgrades could improve a cooling tower’s efficiency, while also saving water in the process. […]

-

Legal & Regulatory

A Comparison of ELG Compliance Options for Flue Scrubber Wastewater

Meeting the requirements of the Effluent Limitations Guidelines (ELG) means careful consideration of the various options. Both biological treatment and zero liquid discharge (ZLD) approaches have their place, but ZLD may offer more flexibility for the future. On September 30, 2015, the Environmental Protection Agency (EPA) issued the final effluent limitation guidelines (ELGs) rule for […]

-

O&M

Proper Scaffold Access Plan Helps Reduce Radiation Exposure

Pipes, valves, turbines, pumps, condensers, and other mechanical components in the radiologically controlled area (RCA, or hot side) of a nuclear power generation facility require routine inspection, testing, maintenance, and, eventually, replacement or repair. When technicians need to work at height, erecting a scaffold often provides the safest and most effective method of access. This […]

-

Legal & Regulatory

Counterfeit Parts: Why Authenticity Is Imperative

When it comes to running a power plant, it’s easy to take the little things for granted. Yet it’s the little things that often have the greatest impact on plant managers’ ability to deliver reliable service for their customers. Take power, for instance. Plant managers are focused on bringing power to their customers. But are […]

-

O&M

Six People Injured by Explosion at Ohio Coal Power Plant

An incident at J.M. Stuart Station—a 2,318-MW coal and diesel generating facility operated by Dayton Power and Light Co. (DP&L)—resulted in six people being treated for non-life-threatening injuries. Several media outlets referred to the event as an explosion, citing nearby residents’ accounts of the incident. At least a few people said they heard and felt […]

-

O&M

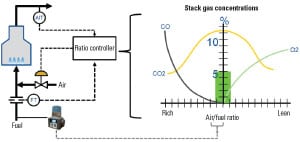

Gas Chromatographs Offer New Technology for Power Plant Burner Control

Background burner control is critical for power and industrial plants because it affects emissions, energy costs, and process efficiencies. For natural gas burners, variations in gas composition can have a

-

Legal & Regulatory

Leaked NRC Email Suggests Pilgrim Nuclear Plant Staff “Overwhelmed”

An email written by the team leader of an ongoing Nuclear Regulatory Commission (NRC) inspection being conducted at the Pilgrim nuclear power plant suggested that the facility’s staff were “overwhelmed by just trying to run the station.” The wide-ranging NRC inspection began on Nov. 28. It is the third and largest inspection conducted as part […]

-

O&M

Boiler Cleaning with Shock Pulse Generators

Increasing plant efficiency and reducing maintenance costs is important for economic power plant operation. One part of the task involves keeping the boiler heating surfaces as clean as possible, which increases heat transfer, reduces maintenance, and avoids unplanned standstills of the plant. Shock pulse generators (SPGs) are an innovative and efficient way to manage boiler […]

-

O&M

“Who Moved My Btus?” The Pitfalls of Extended Coal Storage

Many coal power stations have recently been operating at historically low capacity factors or have even undergone extended economic shutdowns. This can result in coal stockpiles that are exposed to the elements for much longer times than anticipated, resulting in a loss of usable coal energy by several mechanisms. This article explores the severity of […]

-

O&M

Technical Guidance Documents Provide Global Standards

The International Association for the Properties of Water and Steam (IAPWS) is an international nonprofit association of national organizations concerned with the properties of water and steam, particularly

-

O&M

TOP PLANT: Peach Bottom Atomic Power Station, Delta, Pennsylvania

Owner/operator: Exelon Generation and PSEG Nuclear/Exelon Generation When decision-makers choose to increase the maximum output of a nuclear power plant through an uprate, it sets in motion a process that can take many years and countless man-hours to complete. The success of Peach Bottom station’s extended power uprate project shows that all the long hours […]

-

O&M

Ultra-High-Pressure Cavitation Peening Offers New Way to Maintain Components in Operational Nuclear Reactors

To power generation professionals, the word “cavitation” typically has negative connotations, but a new process offers a way to control this normally destructive effect and deploy it as a cost-effective life-extension technique. As operators of commercial nuclear energy facilities consider subsequent license renewals and life extensions, finding new ways to safely maintain reactor components remains […]

-

O&M

Wind Turbine Repowering Is on the Horizon

The world’s first wind farms are reaching the end of their expected lifetimes. As they become outdated, or just inefficient, many developers are considering repowering. Here’s a look at where repowering activity is happening the most and why. Since the world’s first wind turbine used to convert wind energy into electricity was built by Professor […]

-

O&M

Understanding Boiler Code Compliance and Magnetic Level Gages

A magnetic level gage may be an excellent addition to a power plant boiler’s drum-level instrumentation. However, before any changes are made, owners must first understand the specific minimum requirements for water level instrumentation defined by the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. The code requires a functional water gage […]