Coal

-

Coal

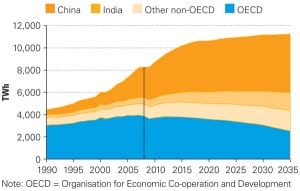

IEA: Global Power Demand to Surge 2.2% Annually Through 2035

Though electricity generation has entered a key period of transition—as investment shifts to low-carbon technologies—world electricity demand is set to grow faster than any other “final form of energy,” the International Energy Agency (IEA) says in its latest annual World Energy Outlook.

-

Coal

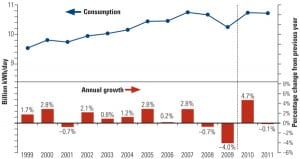

The U.S. Power Industry 2011: The Sequel

If Hollywood were scripting the power industry story for 2011, it would be a sequel to 2010—more of the same, but just not quite as good. Natural gas gets top billing and the accolades, wind power drops to a supporting role, and new nuclear answers the casting call but has yet to get a speaking part. Coal is like Mel Gibson—a talented Oscar winner unlikely to get another leading role. In this, our fifth annual industry forecast report, the story may be familiar, but the price of admission is going way up.

-

Coal

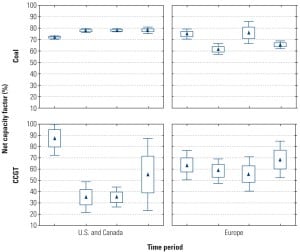

Coal Plants Challenged as Gas Plants Surge

European carbon trading is gradually pushing down coal-fired capacity factors, and operating costs are rising. The U.S. may not have a carbon market, but increasing regulatory requirements are having the same effect on coal-fired generation capacity factors and operating costs. In the meantime, gas-fired assets are enjoying increased usage and lower unit costs.

-

Coal

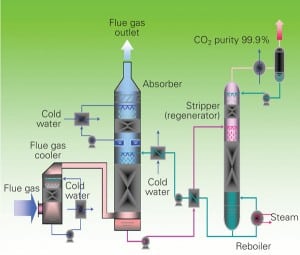

Oxy-Combustion: A Promising Technology for Coal-Fired Plants

For more than a decade Babcock & Wilcox Power Generation Group Inc. and Air Liquide have been developing oxyfuel technology with the goal of using it to concentrate CO2 from pulverized coal-fired power plants and achieve up to 90% CO2 capture and storage. This technology was recently selected for demonstration as part of FutureGen 2.0.

-

Coal

Spain Makes Headway in CCS Efforts

A 14-MW pilot plant built by energy firm ELCOGAS at its 335-MW integrated gasification combined-cycle (IGCC) facility at Puertollano in Spain in September captured its first metric ton of carbon dioxide. Now the company plans to begin tests to procure more technical and economic information about carbon capture and storage (CCS), including how efficient it is to co-produce hydrogen and power with carbon capture processes.

-

O&M

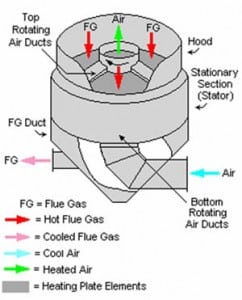

Power 101: Improving the Performance of Boiler Auxiliaries, Part I

Boiler auxiliary equipment often receives no respect for the role it plays in maintaining efficient boiler performance. In this second installment of our Power 101 series, we examine the design and performance of the air preheater.

-

Coal

Efficiency Favored in EPA Greenhouse Guidance To States

A long-awaited Clean Air Act regulatory guidance document released by the Environmental Protection Agency recommends that state air regulators strongly emphasize energy efficiency in determining the most cost-effective and technically feasible greenhouse gas control technologies that must be used by utilities and other major industrial emitters when expanding existing facilities or building new ones.

-

Coal

DOE Warns of Coal Plant Water Supply Shortages

With utilities already alarmed by looming federal regulations that could force construction of expensive cooling towers that would sharply increase water use, a report by the Energy Department’s Argonne National Laboratory warns that nearly 350 U.S. coal-fired power plants are vulnerable to potential water demand or supply conflicts over the next 20 years stemming from increased competition for dwindling water resources—particularly in the Southeast.

-

Coal

Peabody: China, India Leading Coal "Supercycle"

While U.S. coal production has been stagnant in 2010, demand for coal in China and India has sharply risen this year and could represent the early stages of a "long-term supercycle" for the global coal industry, according to Peabody Energy, the world’s largest private coal company.

-

O&M

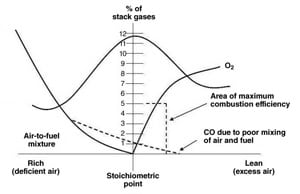

Flue Gas Analysis as a Furnace Diagnostic Tool

Combustion flue gas analysis has been used to optimize the boiler air/fuel ratio for decades. Measuring the amount of excess oxygen and/or carbon monoxide in combustion flue gases gives an indication of boiler efficiency and, thereby, plant operating economics. New sensors make those measurements simple and accurate.

-

Coal

EPA Regulations Accelerate Industry Shift from Wet to Dry Bottom Ash Solutions

Energy efficient and environmentally responsible dry bottom ash technologies will soon be required by regulation. Progressive companies will bring their plants into compliance early because it’s a good business strategy. Here are your compliance options.

-

Coal

Southern Co. Captures Carbon Dioxide at Plant Yates Pilot

The pilot-scale project at Georgia Power’s Plant Yates near Newnan, Ga.—the first step in one of the industry’s largest demonstrations of a start-to-finish coal-fired power plant carbon capture and storage system—reached a significant milestone this September, capturing the greenhouse gas for the first time.

-

Coal

Frog-Inspired Artificial Foam Could Help Trap CO2

In August, researchers from the University of Cincinnati who are working on creating an artificial foam that could absorb carbon dioxide (CO2) from the flue gas at power plants and convert it into biofuel won the grand prize at the 2010 Earth Awards in London.

-

O&M

Abrasion-Resistant Pipe Handles Ash Slurry

Steel piping systems are widely used at coal-fired power plants for a variety of purposes, including the conveying of coal ash slurry to nearby settling ponds, the transfer of limestone slurry to absorber spray towers for removal of SO2 and dilute hydrochloric acid from flue gases, and for transporting away the calcium sulfate by-product of the flue gas desulfurization process.

-

Coal

TVA Eyes Cleaner "Vision" with More Nukes, Less Coal

Responding to looming federal regulations to reduce power plant pollution, the Tennessee Valley Authority’s board signed off on a proposal to shut down 1,000 MW of older coal-fired generation and replace it with an equal amount of natural gas capacity while also pursuing 1,900 MW of demand response and energy efficiency programs and adding 1,140 MW of new nuclear generation by 2015.

-

Coal

EPA Boiler Regulations Will Strangle Construction of New Power Plants

An Environmental Protection Agency plan to tighten emission limits for new and existing industrial boilers has sparked alarmed protests from the biomass generation industry and electric utilities, who say the proposed regulations are so onerous they threaten to shut down existing biomass power plants and already are chilling deployment of new facilities.

-

Coal

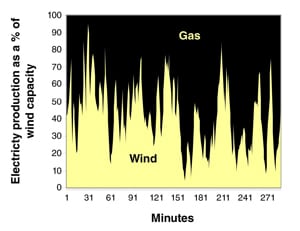

Overblown: Wind Power on the Firing Line, Part I

The conventional and oft-repeated truth is that wind generation directly reduces carbon emissions. Challenging the conventional wisdom has drawn much criticism from wind proponents, but the latest research has shown that wind has had, and will continue to have, negligible impact on the nation’s carbon emissions. The data are convincing and can no longer be ignored.

-

Coal

Overblown: Wind Power on the Firing Line, Part II

Wind electricity production must displace some existing generation. However, its relentless variability imposes daunting challenges for wind integration. Clever engineering schemes can mask the problem, but the data show that wind generation has and will continue to reduce carbon by negligible amounts, but at great expense.

-

O&M

Pulverized Coal Pipe Testing and Balancing

If you want the most accurate test results, it’s worth the extra effort to take isokinetic coal samples from coal pipes when collecting fuel and air measurements. Together, the data collected will allow more accurate balancing of coal pipes, measure fuel fineness, and improve the combustion efficiency of your steam generator.

-

Coal

EPA Air Regulations Shrinking Power Glut

Pending Environmental Protection Agency regulations to slash U.S. power plant emissions likely will lead to the closure of nearly 18% of the nation’s coal-fired generation capacity, trim demand for steam coal by 15% to 31% and boost demand for natural gas by 8% to 16%, a new Credit Suisse analysis concludes.

-

Coal

Top Plant: ADM Clinton Cogeneration Plant, Clinton, Iowa

In the heart of corn country, Archer Daniels Midland is using seed corn that is no longer suitable for planting, along with coal, to power its 180-MW Clinton cogeneration plant. The cogeneration plant, which began operations in 2008, supports ADM’s Clinton corn processing plant, one of the largest corn wet mills in the world. It also supports ADM’s facility that produces renewable plastic from corn sugar. Firing up to 20% biomass along with coal, the new cogeneration plant is capable of providing 100% of the steam and electrical power needs of both facilities.

-

Coal

Top Plant: Brandon Shores Generating Station, Pasadena, Maryland

Constellation Energy Constellation Energy recently completed a series of air quality upgrades on both units at its Brandon Shores Generating Station that included flue gas desulfurization (FGD), baghouse, SO3 control, and mercury reduction by activated carbon injection. The plant’s unique arrangement required long duct runs to the air quality system and a mile-long conveyor for moving barge-delivered limestone to the plant. Treated municipal wastewater was used as wet FGD supply water, and effluent treatment included first-of-its-kind nitrogen removal before discharge to the Chesapeake Bay watershed.

-

Coal

Top Plant: Brunner Island Power Plant, York Haven, York County, Pennsylvania

The 1,456-MW Brunner Island coal-fired plant has implemented advanced environmental improvements in order to be a good neighbor to the residents of south central Pennsylvania. For example, between 2006 and 2010, PPL invested more than $860 million in pollution control upgrades for air, water, and solid waste treatment at the facility.

-

Coal

Top Plant: Dickerson Generating Station, Dickerson, Maryland

Owner/operator: Mirant Corp. Dickerson Generating Station, a 50-year-old facility servicing Maryland and Washington, D.C., was recently upgraded with a flue gas desulfurization system and a unique draft system that allows an electrostatic precipitator and a baghouse to share flue gas cleanup chores on each unit. In addition, state-of-the-art equipment monitoring and diagnostics keep plant reliability high for this baseload unit.

-

Coal

Top Plant: Isogo Thermal Power Station Unit 2, Yokohama, Japan

Unit 2 at J-POWER’s Isogo Thermal Power Station entered commercial service in July 2009. The 600-MW ultrasupercritical unit joins an earlier, similar plant built in 2002. Together, these two new plants replaced 1960s-vintage coal-fired plants and doubled power generation from the small project site. In addition, the new unit improves the plant’s gross thermal efficiency to about 45% while reducing air emissions to those of a gas-fired combined-cycle plant.

-

Coal

Top Plant: Oak Creek Power Plant, Elm Road Units 1 and 2, Milwaukee and Racine Counties, Wisconsin

Adding two 615-MW supercritical pulverized coal units to the 1,135-MW Oak Creek Power Plant is part of We Energies’ ongoing master plan to “Power the Future” of Wisconsin well into the 21st century. The new Elm Road Unit 1 went into service in February, and Unit 2 is expected to start operations during the fourth quarter of 2010. With operations marked by high efficiency and low emissions, these new units will provide large amounts of cleaner energy to the Great Lakes area.

-

Coal

Top Plant: Tolk Station, Earth, Texas

Located in a semi-arid region, this “Texas tough” coal-fired power plant uses a number of smart practices to increase water-use efficiency. For example, a pipeline was constructed to send blowdown water from nearby Plant X for treatment and recycling at the 1,080-MW Tolk Station, making both plants “zero-discharge” facilities. For its environmental stewardship and superior plant operations, the Powder River Coal Users’ Group named Tolk Station its 2010 Plant of the Year.

-

Coal

Map of Coal-Fired Generation in the United States

Courtesy: Platts Data source: POWERmap All rights reserved. No reproduction allowed.

-

Coal

U.S. Coal-Fired Power Development: Down but Not Out

Environmentalists renewed their attacks on coal-fired power development in 2010. At the same time, Congress dithered on cap-and-trade legislation while the Environmental Protection Agency marched forward rules to reduce carbon emissions from coal-fired power plants. Couple the regulatory uncertainty with lean economic times that have flatlined electricity demand growth plus low natural gas prices, and the result is predictable: New coal-fired plant construction is in the doldrums.

-

Legal & Regulatory

Coal Ash Regulation: Playing the Name Game

What’s in a name? Would coal ash labeled as “special” hazardous waste be as easily recycled as that labeled nonhazardous waste?