Busy Week: News and Notes from the Power Industry (July 27, 2023)

A number of companies in the power industry revealed new projects and other interesting developments this week. The following are some the more noteworthy announcements that POWER has been monitoring.

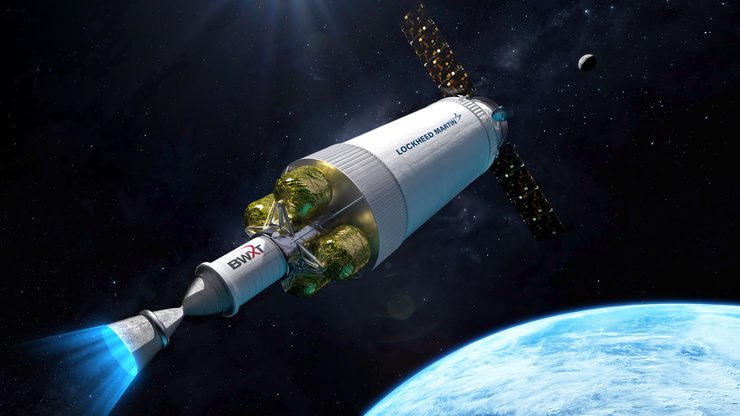

BWXT to Provide Nuclear Reactor Engine and Fuel for DARPA Space Project

BWX Technologies Inc. (BWXT) announced on July 26 that its reactor and fuel will be key components in the world’s first demonstration spacecraft using nuclear thermal propulsion. Working as part of a team led by Lockheed Martin, BWXT Advanced Technologies LLC will complete final design of the nuclear reactor, manufacture the reactor’s hardware and fuel, assemble the components, and deliver the fueled reactor as a complete subsystem for integration into the Defense Advanced Research Projects Agency’s (DARPA’s) Demonstration Rocket for Agile Cislunar Operations, known as DRACO (Figure 1).

“The award of this contract further demonstrates BWXT’s ability to design, manufacture, and deploy nuclear reactors and fuel on a scale that is unmatched elsewhere in the world today,” Joe Miller, president of BWXT Advanced Technologies LLC, said in a statement. “This partnership with Lockheed Martin working for DARPA adds another important dimension to BWXT’s already-impressive lineup of nuclear reactor designs for commercial and defense applications.”

The reactor’s energy will enable propulsion that allows DRACO to maneuver through space with great speed and agility for an extended period of time. BWXT said the nuclear thermal propulsion system is designed to be extremely safe and reliable, using high-assay, low-enriched uranium (HALEU) fuel to rapidly heat a super-cold gas, such as liquid hydrogen. As the gas is heated, it expands quickly and creates thrust to move the spacecraft more efficiently than typical chemical combustion engines.

The spacecraft is targeted for a 2027 launch from Earth in “cold” status (meaning that the reactor is turned off as a part of launch safety protocols) by a conventional rocket, and then the reactor will be powered on once the spacecraft attains an appropriate location above low earth orbit. Work on this program will be conducted primarily at BWXT’s Mt. Athos Road complex near Lynchburg, Virginia.

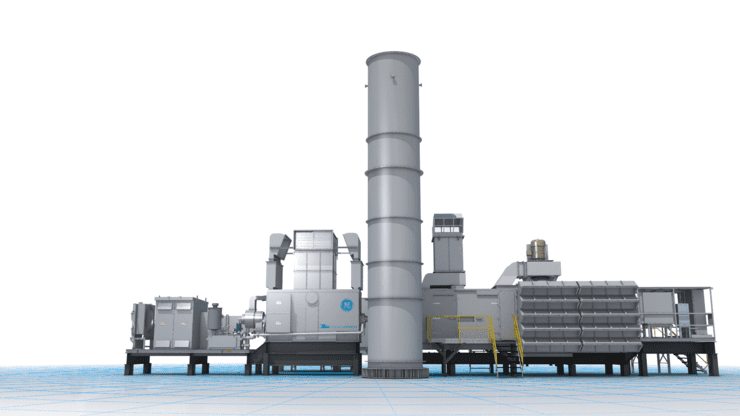

GE Vernova Secures Eight-Unit Aeroderivative Order from the Electricity Supply Board of Ireland (ESB)

GE Vernova’s Gas Power business announced on July 27 orders for both the supply and the operation and maintenance (O&M) activities of a simple cycle power plant consisting of eight GE LM2500XPRESS aeroderivative gas turbines (Figure 2) from the Electricity Supply Board of Ireland (ESB) for its facility in Shannonbridge, Ireland. The Shannonbridge Power Plant will be a new temporary reserve power plant designed to deliver up to 264 MW to support Ireland’s electricity supply. The Shannonbridge Power Plant is being constructed in central Ireland and is expected to start operation during the 2023–2024 winter season and serve as a reserve power plant through to the end of the 2026–2027 winter season.

The Shannonbridge project follows GE’s recently announced 200-MW emergency power plant construction project at North Wall in the Dublin area. Similar to ESB’s North Wall Power Plant, which is powered by six GE LM2500XPRESS, the Shannonbridge Power Plant will not be available to the open electricity marketplace; instead, the project will only be operated against a specific instruction to support the Irish grid when needed.

“Emergency power plants, like Shannonbridge and North Wall, need to start quickly and run when electricity demand is high and generation capacity from other sources available on the system is at risk of not meeting demand,” Joseph Anis, president and CEO, Europe, Middle East, and Africa, at GE Vernova’s Gas Power business, said in a statement. “We’re proud to continue to work with ESB and to be bringing one of the best and most efficient aeroderivative packages and O&M services at the Shannonbridge Power Plant and contribute to the security of Ireland’s electricity supply.”

Babcock & Wilcox Awarded Contract to Study Bioenergy with Carbon Capture and Storage (BECCS) Conversion for Coal Power Plant in Michigan

Babcock & Wilcox (B&W) announced on July 26 that it had been awarded a contract by NorthStar Clean Energy to conduct a Bioenergy with Carbon Capture and Storage (BECCS) engineering study to convert a coal-fired power plant in Michigan to use biomass fuel and retrofit the plant with B&W’s SolveBright carbon dioxide (CO2) capture process.

“BECCS projects hold tremendous potential in helping the world achieve a goal of net-zero carbon emissions by 2050,” Joe Buckler, B&W senior vice president of Clean Energy, said in a statement. “Capturing CO2 from biomass combustion allows a plant to generate energy and be a net-negative emitter of greenhouse gases. This in turn allows the plant owner to offset emissions from other sources such as through the sale and trade of carbon credits.”

The study is the first phase of a commercial-scale project partially funded by the U.S. Department of Energy. Babcock & Wilcox Construction Co. LLC will manage construction and mechanical scope of the study and commercial phase.

NorthStar Clean Energy plans to eliminate CO2 emissions from the plant by converting the 75-MW TES Filer City Station power station in Filer City, Michigan, to use sustainable biomass as fuel. The plant is jointly owned by NorthStar Clean Energy (a subsidiary of Jackson, Michigan–based CMS Energy Corp.) and Houston, Texas–based Tondu Corp. The CO2 generated by the plant would be captured using B&W’s SolveBright post-combustion CO2 scrubbing process, which provides for flexibility in the regenerable solvent used to isolate CO2 for sequestration or utilization.

Westinghouse Awarded Trio of Grants from UK Nuclear Fuel Fund

Westinghouse Electric Company announced on July 27 that the UK government’s Nuclear Fuel Fund had awarded three grants to upgrade and expand the company’s Springfields Fuel Fabrication Facility (Figure 3) to support the UK’s next-generation nuclear reactors.

“This investment from the Nuclear Fuel Fund is a vote of confidence in the capabilities of our Springfields manufacturing site,” Westinghouse President of Nuclear Fuel Tarik Choho said in a statement. “We are excited for the future of nuclear energy in the UK and the role Westinghouse will continue to play in its success.”

Westinghouse said the three awards totaling £10.5 million “will future-proof the UK nuclear fuel industry by developing more variants of light water reactor fuels,” including for the AP1000 reactor and the AP300 small modular reactor. The funding also supports potential production of high-enriched, low-assay uranium-based (HALEU) advanced nuclear fuels for new Generation III and IV fission reactors. Additionally, Westinghouse said it will partner with Terrestrial Energy and the National Nuclear Laboratory to pilot supply of enriched uranium tetrafluoride (UF4) and molten salt fuel for use in Terrestrial’s Integral Molten Salt Reactor.

—POWER staff (@POWERmagazine).