Ansaldo Energia Reports Hydrogen Breakthrough for Gas Turbine Sequential Combustion Technology

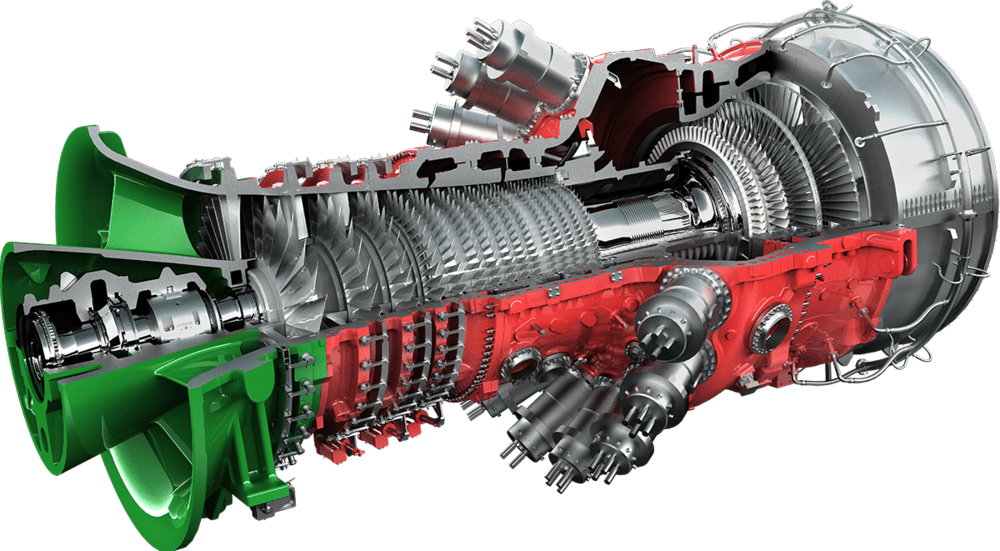

Ansaldo Energia has successfully demonstrated its constant pressure sequential combustion (CPSC) technology—designed for a novel, hydrogen-optimized combustor based on its flagship GT36 H-class gas turbine model—can flexibly operate with up to 100% hydrogen fuel.

The breakthrough announced on Feb. 13 marks a major triumph for the FLEX4H2 (or Flexibility for Hydrogen) program, a four-year European project seeking to design, develop, and validate an efficient and highly flexible 100% hydrogen-capable gas turbine combustion system for large heavy-duty gas turbines.

The Italian power generation solutions firm said the milestone was achieved after successful testing of GT36 combustor prototypes at a dedicated test facility in Cologne, Germany. “The tests highlighted the combustor’s ability to seamlessly switch between natural gas and hydrogen, demonstrating its remarkable fuel and operational flexibility,” the company said.

POWER has requested more details about the testing and will update this article as they are received.

Based on Ansaldo’s Constant Pressure Sequential Combustion Technology

A core FLEX4H2 effort has been to develop the novel combustor’s design based on Ansaldo’s CPSC technology, a second-generation combustion system developed for Ansaldo’s flagship GT36 H-class gas turbine (760-MW in combined cycle) combustors.

As POWER has reported, sequential combustion evolved from burner technology applied to Ansaldo’s GT26 F-class and GT24 gas turbines. In the GT26, sequential combustion is implemented with two combustion stages separated by a high-pressure turbine: the first stage (EV) operates at pressures greater than 30 bar, while the second stage (SEV) operates at roughly half of the EV pressure. In the GT36, no high-pressure (HP) turbine is implemented, but the sequential combustion concept is maintained.

“Due to the high-burning velocity and high-flame temperature, standard gas turbine combustion technology struggles at high hydrogen content with high [nitrogen oxide (NOx)] emissions and the risk of flashback,” Ansaldo noted. “This usually results in the necessity of power derating to comply with required standards. Based on two successive combustion stages, the GT36 recovers the derating of the first stage by shifting the fuel into the second stage. This allows for full operational flexibility, low NOx, and no derating.”

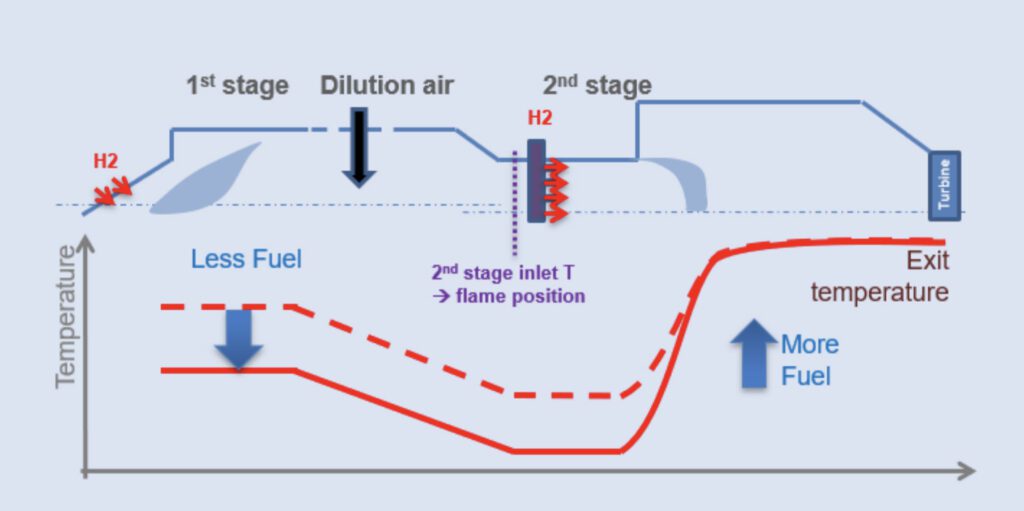

Turbulent flame speed (driven by equivalence ratio and fuel composition) defines the flame location of the first stage. In the second stage, flame location is more influenced by inlet temperature, along with the fuel composition, FLEX4H2 clarified. “In case of a major change in fuel reactivity—e.g. replacing natural gas with a hydrogen-based fuel—flames tend to flashback due to their faster flame propagation speed and shorter self-ignition time,” it said.

A CPSC system essentially tempers the effect of higher fuel reactivity by adjusting the fuel split between the first and second stages, it added. If the fuel’s reactivity increases, less fuel is allocated to the first stage to lower the equivalence ratio and maintain optimal turbulent flame speeds, while the second stage compensates with more fuel to recover any power loss from the first stage adjustments. A lower first-stage flame temperature produces a lower inlet temperature in the second stage, and this, in turn, balances the self-ignition time at optimum values and ensures the second-stage flame is at its designed location, it said.

A Triumph for FLEX4H2

According to Vasileios Stefanis, Ansaldo head of New Units & Service Technologies, FLEX4H2 chose CPSC as its core technology for the development of the improved combustion system, given its capabilities to maximize cycle efficiency while keeping emissions at very low levels.

As it stands, the GT36 can already combust 70% hydrogen in natural gas, Ansaldo has told POWER. However, the FLEX4H2 project has set out several challenging goals for its development and validation of the novel combustor. These include ensuring the 100% capable combustion system will be capable of operating at the most challenging hydrogen combustion conditions, such as H-class operating temperatures and pressures, which are required for the highest cycle efficiency. As crucially, the novel system must also meet stringent European emissions targets for NOx and carbon dioxide without the use of diluents.

“Modern gas turbines must target ultra-high firing temperatures, robust flame stabilization and the widest flexibility both in respect to engine operation and fuel type,” Stefanis recently said in an update published by ETN Global, a trade group comprising the entire gas turbine technology value chain. “Sequential combustion has demonstrated its advantages towards such extremely ambitious targets,” he said.

“The use of two combustion stages, one utilizing aerodynamic flame stabilization, driven by flame propagation, and the other stabilized by autoignition, provides outstanding performance in terms of both NOx emissions, turn-down capability, and fuel flexibility,” he noted. “The intrinsic flexibility of sequential combustion technology has already been shown to enable clean and efficient operation on a wide variety of fuels with very high hydrogen contents. NOx emissions can be brought down to very low levels thanks to the short post-flame residence time achieved in the sequential combustor as well as the advantage of an auto-ignition stabilized flame burning into the hot products of the first stage, characterized by lower oxygen content, thus inhibiting NOx formation.”

FLEX4H2 will seek to demonstrate the system in a rig at “fully reproducing engine operating conditions,” including for mass-flows, temperatures, and pressures, Stefanis said. In addition, the improved combustor system “should be fully retrofittable to existing gas turbines, thereby providing significant opportunities for refurbishing existing assets.” Ultimately, the project seeks to achieve a technology readiness level (TRL) of 6, which should pave “the path towards commercial deployment shortly after project completion,” he said.

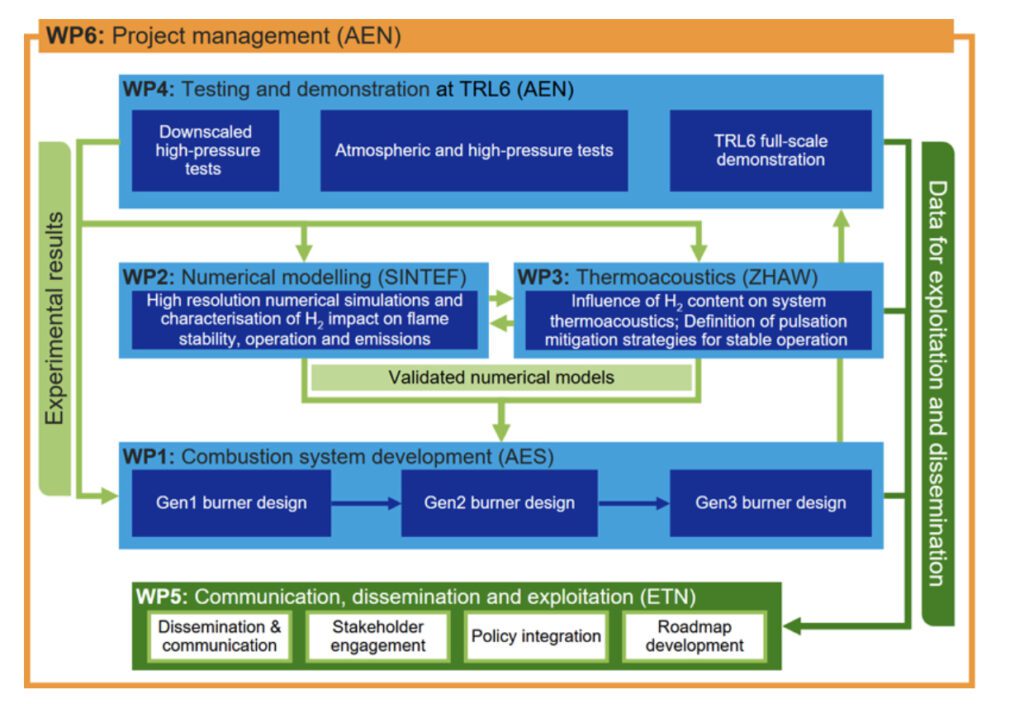

FLEX4H2, which is co-funded by the Clean Hydrogen Partnership—a European public-private coalition that supports hydrogen research and innovation, the European Union (EU), and Switzerland, kicked off in January 2023 and will run until December 2026. FLEX4H2 partners include entities from six European countries.

Along with Ansaldo, these include Arttic Innovation (Germany), Centre Européenne de Recherche et de Formation Avancée en Calcul Scientifique – CERFACS (France), Deutsches Zentrum für Luft- und Raumfahrt – DLR (Germany), Edison (Italy), ETN Global (Belgium), Sintef Energi (Norway), Ansaldo Energia Switzerland (Switzerland), Zürcher Hochschule für angewandte Wissenschaften – ZHAW (Switzerland).

Ansaldo, as the project’s coordinator, will integrate all activities. “The key to the success of this project lies in the very well-balanced multidisciplinary composition of the consortium, bringing together one of the world’s leading players in the sector of power generation plants with renowned leading research partners, a gas turbine industry stakeholder representative association as well as a major power plant operator,” Stefanis noted.

Ansaldo is leading two work packages, including the development of the combustion system design. “Additionally, Ansaldo Energia will develop the design for manufacturing and coordinate the production of combustor prototype hardware, as well as their tests and validation,” Stefanis said.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

Editor’s Note: This story is being updated as more details are received. We encourage you to revisit this article or check our website for the latest updates.