Though often lumped together under the term “energy storage,” the field is in fact a wide range of technologies ranging from well established to speculative, each with different functions, advantages, and drawbacks. The discussion below focuses on existing grid-scale (greater than 1 MW rated power) projects and is generally ordered by level of deployment.

Pumped Storage Hydroelectric (PSH). Electricity is used to pump water to higher elevation, where it is stored and released when generation is required. PSH makes up the lion’s share of installed capacity worldwide, around 99%. Most projects are connected to conventional hydroelectric plants, though some are standalone. PSH is best suited for time-shifting, as ramp times are fairly slow. All but one employ freshwater; one seawater PSH facility exists in Japan.

Thermal Storage (TS). Storage of thermal energy takes two forms: storage of chilled water or ice to increase efficiency of cooling systems (building or power plant), and storage of heat to allow time-shifting of plant output, typically solar. Approximately 20 projects of the latter type over 10 MW are in operation worldwide; the largest is the Solana Solar Generating Plant in Arizona. Ramp rates tend to be slow, so TS is mostly used for time-shifting.

Compressed Air Energy Storage (CAES). Air is compressed and stored, then released into an expansion turbine to generate power as needed. Only two large-scale projects exist, one in Alabama and one in Germany, and both are incorporated into gas turbine generating plants. The use of stored compressed air significantly increases efficiency and response time of the gas turbines. Though large amounts of energy can be stored with this method, CAES is handicapped by the problem of what to do with the heat generated by compression, which must be removed before storage and restored before use. Various methods have been proposed to capture and store the heat, but all are still in the research or pilot demonstration phases. CAES can ramp faster than gas turbine peaking plants, making it useful for peak shaving, but it is still used mainly for time-shifting.

Sodium-Sulfur Batteries (NaS). NaS batteries use molten sulfur as the positive electrode and molten sodium as the negative electrode, separated by a ceramic barrier that serves as the electrolyte. NaS batteries must be maintained at high temperature (greater than 300C) to keep the electrodes liquid. While the technology has been around since the 1960s, research and deployment has taken place almost entirely in Japan, which has around 1,600 MWh of NaS battery capacity installed. A related design employing sodium and nickel chloride was commercialized in the 1990s and is beginning to see testing at grid scale. The technology is useful for smoothing output from renewables, but lacks the response time to manage moment-to-moment fluctuations.

Lithium-Ion Batteries (Li-ion). This technology is actually a range of battery designs characterized by the transfer of lithium ions between various types of electrodes. In part because they are scaled up by combining individual cells, Li-ion batteries have been held back at grid scale by their high cost (though this also makes them highly customizable). However, Li-ion batteries have high energy density, low maintenance requirements, and among the fastest response times of existing methods, making them ideal for short-term on-site storage, such as for balancing output from remote wind and solar facilities. Recent advances have made larger battery arrays more economic, and containerized MWh-scale units are now commercially available and seeing increasing deployment. The largest, at 32 MW and 8 MWh, is installed at the Laurel Mountain wind farm in West Virginia.

Redox Flow Batteries. Unlike solid-state batteries, flow batteries store their energy in a liquid electrolyte rather than a solid electrode. Electricity is generated as the electrolyte flows across electrochemical cells and releases electrons; the process is reversed during charging. (Redox refers to the reduction and oxidation reactions taking place.) One advantage of flow batteries is that they can be rapidly recharged by replacing the electrolyte, and system energy can be scaled up by increasing the size of the electrolyte tanks. They are better suited to hours-to-days storage, as their response time is slower than Li-ion designs. Commercial battery systems employing vanadium cells have been in operation for about a decade, mostly in Japan. Another design employing zinc cells and bromine electrolyte is undergoing grid-scale testing.

Lead-Acid Batteries. The familiar car battery has seen relatively little use at grid scale despite its low cost because its low energy density and short cycle time make it poorly suited for most applications. Advanced designs intended to overcome these problems, for example by incorporating supercapacitors, have drawn substantial attention, but only one large-scale test project in Texas is currently operational.

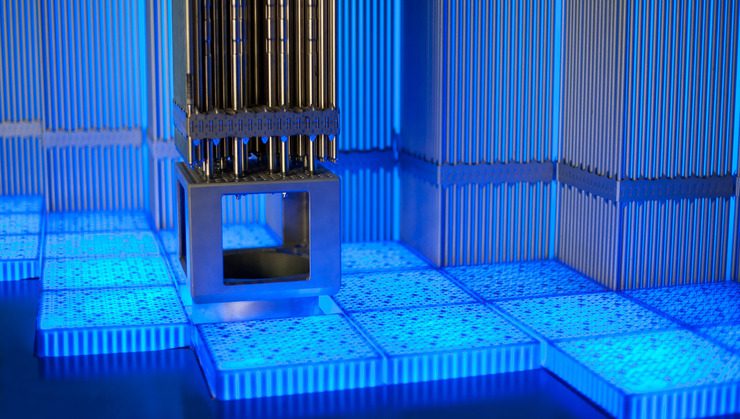

Flywheels. Electricity is stored as kinetic energy in a spinning rotor. Modern designs use magnetically suspended rotors spinning in a vacuum, making them nearly frictionless. The rotor is part of a motor-generator system that adds or draws off energy as needed. Their nearly instantaneous response time makes flywheels best suited for frequency regulation and other high power, low-energy applications. Only two grid-scale projects currently exist.

Power-to-Gas (P2G). Part storage and part manufacturing process, this method uses electrolysis to convert excess electricity to hydrogen and, with additional reactions, synthetic methane. When needed, the hydrogen or methane can be used in fuel cells or gas turbines. While P2G has the advantage of using existing gas infrastructure, there are challenges in moving economically to grid scale. Two 1-MW to 2-MW facilities are in operation in Germany.

Liquid Air Energy Storage (LAES). Air is compressed and chilled to a liquid state and then regasified in a turbine. One 350-kW, 2.45-MWh pilot project is in operation in the UK, with plans for future expansion to other sites.

This primer was prepared with assistance from the Energy Storage Association (www.energystorage.org).

—Thomas W. Overton, JD is a POWER associate editor.